HEALTH INSPECTION CHECKLIST TEMPLATE

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

How to use the Health Inspection Checklist

Although your local health inspector may look intimidating, these inspections must not be feared! A great tool to prepare your team for such inspections is a trusted Health Inspection Checklist.

Here are the steps to complete your Health Inspection Checklist PDF:

- Download the checklist. Enter a valid email address and click on "Download." The checklist will be automatically saved in your downloads folder.

- Fill each line with the relevant health inspection checklist items (and print more pages if needed).

- Familiarize your team with the key areas of a health inspection. Include food safety regulations.

- Organize each task according to key areas.

- Review and add more tasks to the existing template.

- Review the list periodically to make sure it's up-to-date

Prefer a pre-filled, customizable version? Check out our health inspection checklist tool.

Key points covered:

- A Health Inspection Checklist is a detailed document used to guide food handlers on key areas that need to be reviewed for compliance.

- Health inspections evaluate the level of food safety of your business and correct any oversight.

- Tasks in a restaurant health inspection checklist must be done almost daily to ensure compliance with health requirements.

- As a food business owner or manager, you can initiate in-house inspections to prepare your employees for a surprise health inspection.

- Health inspections focus on food sanitation, employee hygiene, pest control, waste management, and core food handling practices.

- Health inspections can be graded through a number, letter, or point system.

- FoodDocs' digital Food Safety Management System can automatically generate a customizable digital Health Inspection Checklist.

WHAT WE'LL COVER:

- 8 Tips for Using This Health Inspection Checklist

- Health inspection checklist meaning

- Food businesses that need a health inspection checklist pdf

- Benefits of Health Inspection Checklist

- How to create a Health Inspection Checklist

- Preparing for a health inspection

- Health inspection grading scales

- Should I digitize my health inspection checklist?

- Digital solutions for health inspections

- Health inspection checklist to ensure compliance with food safety principles

- Customizable system to fit your business needs

- Step-by-step instructions to help train food handlers

- Real-time overview to save time from supervision

- Frequently Asked Questions

8 Tips for Using This Health Inspection Checklist

Using a health inspection checklist effectively means more than just ticking boxes. It’s about making the checklist an active tool for daily food safety management. Here are some practical tips on filling out the checklist items and avoiding common mistakes:

1. Verify each item with a physical check

For every line on the checklist, go and inspect that item or practice in real life before marking it. Don’t rely on memory or assumptions. For example, if the checklist asks “Are all refrigerators at 40 °F (4 °C) or below?”, actually check the thermometer reading of each unit.

A common mistake is to assume cooling units are fine because they were last time – only to find a unit has drifted out of safe range. Always measure and record (e.g. “Fridge #3 at 38 °F, OK”).

Similarly, if an item says “Handwash stations stocked with soap and paper towels,” do a quick walk to each station to confirm supplies, rather than assuming your staff refilled them.

2. Use clear yes/no or N/A answers and notes

Follow the checklist format. Typically you might check “Yes” (compliant) or “No” (needs attention) for each line. If something does not apply (N/A) to your operation (for example, you have no salad bar to monitor), mark it as such to avoid confusion. For any “No” response indicating a problem, add a brief note about what was wrong and what corrective action you took.

For example, if you mark “No” for “Food properly labeled & dated” because you found an undated prep item, your note might be “One container of soup in walk-in missing date – discarded.” This documentation shows that you not only identified an issue but also addressed it on the spot.

A frequent mistake is failing to note corrections; inspectors appreciate seeing that problems are recognized and fixed promptly, even during your self-audits.

3. Don’t pencil-whip the checklist

“Pencil-whipping” refers to the bad habit of hurriedly checking off items without actually doing the verification – often to save time or avoid hassle. This defeats the whole purpose of the checklist and can lead to blind spots in your food safety.

Avoid rushing. It’s better to spend an extra 10 minutes doing the checklist properly than to have an incident or violation later because an issue was overlooked. Emphasize accuracy over speed when training staff on using the list.

Using the checklist diligently can catch minor issues (like a sanitizer bucket that’s lost strength or a thermometer in need of calibration) before they escalate into major violations.

4. Provide examples and clear criteria

When filling out the checklist, ensure everyone understands what “compliant” looks like for each item. For instance, simply stating “No cross-contamination” on a list is abstract. You might clarify in training that this means raw meats are stored below ready-to-eat foods, separate cutting boards are used, and sanitizer is used on surfaces between tasks.

Giving specific examples (“e.g., raw chicken must be on bottom shelf in cooler, with a pan to catch drips”) helps your team know exactly what to check for and how to mark the checklist. If possible, attach reference images or brief guidelines to certain checklist items – a photo of a correctly organized cooler or a properly set up handwash sink can serve as a visual standard.

5. Leverage visual aids for training

To get your staff comfortable with the checklist, use visual examples during training sessions. Consider showing a sample completed checklist – essentially a filled-out form that illustrates how each section should look when done right. Walk through it with the team, explaining why each item was marked a certain way.

Visuals are powerful and help staff retain information better when they see a concrete example. You might even conduct a mock inspection as a demonstration, with one person acting as the “inspector” and another filling out the checklist, so everyone can observe the process.

Many trainers recommend using demonstrations and even photos or screenshots as part of food safety training, since these visual aids make abstract rules more concrete. For example, during orientation you could display a photo of an actual dry storage area and have trainees identify what is correct or not (expired labels, items on floor, etc.), then show how that corresponds to checklist items.

Tying the checklist to real-world scenarios helps employees learn to see what the checklist is asking for.

6. Make it part of the routine

The checklist shouldn’t collect dust on a clipboard – integrate it into daily work schedules.

For example, you might assign the opening manager each day to run through a subset of the checklist (verifying that critical items like refrigeration, hot water, and sanitizer levels are in order before service). Mid-shift, a supervisor could spot-check a few items, and at closing, another brief walkthrough ensures everything is left in compliance.

Folding these checks into existing routines (like during pre-shift meetings or kitchen shutdown procedures) turns compliance into a habit rather than a scramble. Some restaurants even incorporate a quick “food safety huddle” – a short team meeting – once a day or week to review any issues found on checklists and reinforce important points.

The key is consistency. When staff members see that management is reviewing the checklist every day, they understand its importance. Over time, this builds a culture where meeting the checklist becomes second nature, greatly reducing anxiety when an official inspection occurs.

7. Use the checklist as a training tool

Especially for new hires, use the health inspection checklist as a roadmap of what they need to learn. For instance, if one section of the checklist is “Personal Hygiene”, a trainer can go through each bullet (clean uniform, hair restrained, handwashing, no jewelry, etc.) and demonstrate the expected standard, checking off as the trainee practices or demonstrates understanding.

This way, the checklist doubles as a skills checklist during onboarding. Encourage employees to ask questions if they are unsure how to evaluate something on the list – for example, “How do I know if the sanitizer concentration is correct?” – so you can teach them (with tools like test strips in this case).

Training each role on their relevant checklist items will empower staff to maintain standards autonomously.

8. Retain the completed checklists for your records

Whether you use paper forms or a digital app, keep past checklists archived. These can be reviewed to spot trends (e.g., if “freezer temperature” is often an issue on Mondays, maybe the defrost cycle needs adjusting) and will also be invaluable in demonstrating due diligence to health inspectors.

If an inspector sees months’ worth of diligent checklist logs, it builds confidence that your team stays on top of food safety even when they’re not there.

Health Inspection Checklist PDF: Understanding the Critical Points of Focus

Regular health inspections are critical to food safety and public health because they serve as the frontline defense against foodborne illness. In the United States alone, the CDC estimates that roughly 48 million people get sick from foodborne diseases each year, with 128,000 hospitalizations and 3,000 deaths. Many outbreaks are traced back to restaurants and food outlets, with about 800 foodborne outbreaks reported annually, many of which happen in restaurant settings.

By routinely inspecting food businesses, health officials can catch issues early (e.g. unsafe cooking practices or improper refrigeration) and enforce corrections before those issues harm customers. That's why restaurant inspections are one of the main tools for preventing foodborne illness in the community.

Health inspection checklists highlight the critical points of focus that inspectors (and food operators) must monitor to keep food safe. These typically cover areas like food storage temperatures, cooking and reheating procedures, employee hygiene, cleaning/sanitation of equipment, pest control, and waste management.

There’s good reason for this focus: mistakes in these areas can directly lead to contamination or bacterial growth. For example, failing to keep poultry at the right temperature or employees not washing hands can introduce pathogens that cause illness. Meanwhile, many common violations found during inspections involve general sanitation and maintenance. Studies have found that the most frequently cited issues are things like unclean equipment surfaces or dirty floors/walls (which might not directly spoil food but indicate poor overall hygiene).

Critical violations (such as unsafe food temperatures or cross-contamination) tend to be less common, but when they do occur, they are treated very seriously because they pose an immediate risk. This is why inspectors devote so much attention to these core areas: any lapse in a critical control point can have severe public health consequences.

Beyond protecting public health, passing inspections consistently is vital for a food business’s reputation and success. Customers today are very aware of health scores. About 70% of diners say that health code violations would deter them from choosing a restaurant. In places with grading systems, a low grade or a history of violations can drive patrons away and even make local news.

On the flip side, maintaining high standards (often by using checklists to self-audit and stay prepared) not only prevents outbreaks but also signals to customers that your establishment is trustworthy.

One study in Los Angeles found that restaurants with an “A” grade for hygiene had measurably higher sales compared to those with poorer grades. Underscoring that food safety isn’t just a regulatory issue, it’s also good business. In short, regular inspections backed by diligent daily practices protect your guests from getting sick and protect your business from the fallout of failed inspections.

As part of the common restaurant health code mandates of many food safety agencies and environmental health offices worldwide, health inspections of food businesses must be conducted. When these inspections are performed, most employee teams become too nervous to function and mess up the process.

How health inspectors use inspection checklists

During a health inspection, inspectors use standardized checklists to assess compliance with food safety regulations. Each checklist item corresponds to a specific regulatory requirement and is evaluated through observation, measurement, and record review.

Inspection findings are commonly categorized as:

-

Critical violations, which pose an immediate risk to food safety or public health

-

Non-critical violations, which relate to maintenance, cleanliness, or procedural issues

While checklists help standardize inspections, final inspection outcomes are determined by the enforcing authority, not by the checklist alone.

What is a Health Inspection Checklist?

A health inspection checklist or health inspection form is used to evaluate the safety of a food service facility setup, cleaning routine, operational practices, employee health status, and personal hygiene. It is a comprehensive and structured document restaurant health inspectors use to evaluate food safety compliance in the food industry.

It is used to reduce contamination risk factors and prevent food service establishments from releasing hazardous foods to any consumer or from committing common health code violations.

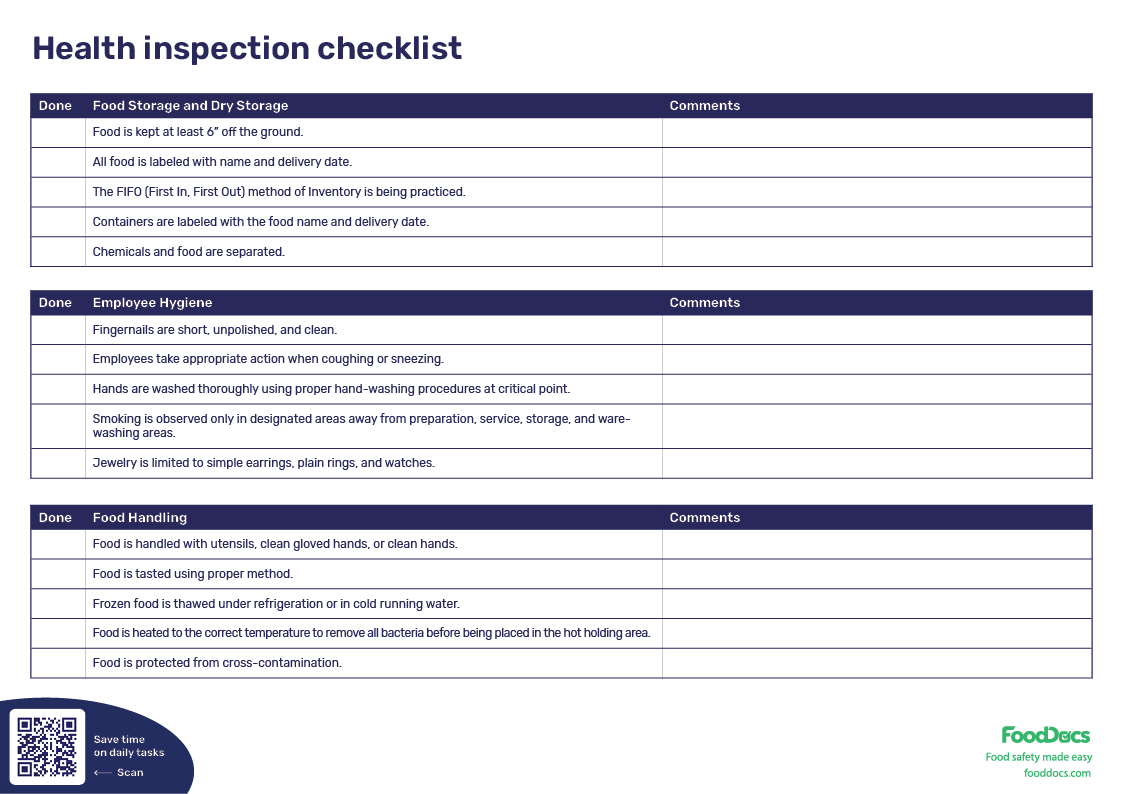

A health inspection checklist covers various aspects of food safety in the facility, such as food handling and storage practices, sanitation, employee hygiene, equipment maintenance, and overall safety protocols.

Checklists are commonly done through pen and paper as part of food safety plans. To help you ensure accurate food safety compliance, consider trying food safety software like FoodDocs. Our easy-to-use intuitive software features automatically generated health inspection checklists that can be fully customized based on your specific operations.

What are the key areas of a health inspection?

During an inspection, inspectors focus on several key areas to ensure the well-being of individuals and the community. These key areas typically include food handling and storage practices, sanitation and cleanliness measures, and the implementation of proper health protocols, all aimed at maintaining a safe and healthy environment for employees, customers, or residents.

Some of the key areas and corresponding tasks included in a health inspector checklist include:

- Food storage

- Storage parameters for hot food and cold food

- Cleanliness of food equipment storage areas

- Correct temperature control of storage areas

- Refrigerating perishable foods (e.g., ground meat and poultry)

- Correct storage of cleaning chemical products

- Employee hygiene and health

- Proper hand-washing procedures of food handlers

- Wearing of proper dress code

- Proper action when coughing or sneezing

- Proper use of gloves

- Food handling practices

- Cooking thoroughly to the correct internal temperature

- Preventing cross-contamination

- Ensuring a clean food preparation process

- Proper rotation of food inventory (FIFO method)

- Cleaning and sanitation

- Mop sink, clean bathroom stalls, and cooking stations

- Cleaning of utensils

- Sanitizing food surfaces

- Food prep tools must always be cleaned in between uses

- Cleaning supplies are stored in a dedicated area

- Dedicated area in the kitchen for employee hand washing

- Dedicated 3-compartment sink for sanitation

- Waste management

- Emptying garbage bins or garbage cans

- Pest control

- Proper methods for rodent control

- Removal of signs of pest infestations (e.g. droppings and chewed wood)

- Documentation and recordkeeping

- Organizing monitoring tasks and checklists

- Keeping food allergen info for products

A restaurant health inspection checklist can be routinely used in your food business to reduce the risk of contamination. All involved activities in a cleaning checklist for restaurants and other food establishments are designed to outline the standards for cleanliness in a food business to protect community health.

Who needs a Health Inspection Checklist PDF?

Health inspection checklists will benefit every team of food handlers in a food business in preparation for any inspection, whether surprised or announced. Business owners or food safety managers can use this tool to evaluate and maintain food safety standards regularly.

Health inspections are common for businesses, such as:

- restaurants,

- food trucks

- commercial kitchens,

- food retail,

- food production, and

- institutional food service.

Food businesses require constant compliance with food safety regulations and one of the best ways to ensure this is to conduct health inspections. Food safety and health agencies conduct such inspections to help protect public health from cases of foodborne illnesses.

What are the benefits of a Health Inspection Checklist?

Health inspection checklists can be used for in-house evaluation of operations. They are effective for maintaining compliance with food safety regulations and can help protect consumers from potential hazards. This type of checklist requires constant changes and improvement.

A restaurant or any other food business would have an objective list of food safety standards and health indicators when using a healthy inspection checklist.

This inspection checklist usually contains a definitive list of food safety guidelines by the local health department to prevent poor health outcomes due to food contamination. They can be mainly used to ensure that you are producing safe food items and that public health is protected from foodborne illnesses or any related injuries.

In addition to preventing food safety issues, a health inspection checklist offers several other benefits:

Standardization of procedures

A checklist turns abstract regulations into a concrete list of tasks. By following a standardized health inspection checklist, your team ensures all critical areas are checked consistently (from kitchen to storage to bathrooms). This reduces the chance of something being overlooked.

Every shift and every location (if you have multiple outlets) will adhere to the same benchmarks, so you don’t rely on memory or individual judgment for what to clean or monitor. Standardization is crucial in training new staff as well. They have a clear reference for what “compliant” means in daily practice.

Early detection and prevention

Using the checklist regularly helps in early detection of potential hazards or violations. It essentially forces you to inspect yourself frequently. If something is starting to go wrong, e.g., a fridge is trending warm or you start seeing mouse droppings in a storeroom, the checklist will surface that issue in your routine checks so you can fix it long before an inspector (or a customer) would notice.

This proactive approach can prevent minor issues from snowballing into serious problems. It’s always easier (and cheaper) to address a risk on your own timeline rather than during a crisis or failed inspection.

Improved focus on key principles

Health inspections cover many aspects of operations, which can feel overwhelming. A good checklist helps you prioritize and focus on what matters most for safety.

For instance, it will highlight critical control points (e.g., cooking, cooling, handwashing) so you can allocate time and resources to those first. Less critical tasks (like maybe some general maintenance) are on the list, too, but the checklist structure can guide your team to tackle high-risk issues with urgency.

This focused approach not only helps with passing inspections but genuinely makes the environment safer.

Accountability and team training

A health inspection checklist is ultimately an accountability tool. By assigning checklist items to employees or requiring initials, you create responsibility for each safety task. Team members know their names are effectively tied to certain duties (e.g., the opener who checked the sanitizer logs). This transparency motivates staff to actually complete the task, not just skip it, since it’s clear who is responsible.

Over time, this builds a sense of ownership in the team; they become proud of keeping things up to standard. Moreover, the checklist doubles as a training outline. It reminds staff what they need to know and do. New hires learn faster when they have a checklist to follow, and veterans stay sharp because the checklist keeps them from getting complacent.

In short, it institutionalizes food safety knowledge among your staff.

Streamlined management and delegation

For managers, a health inspection checklist makes it much easier to delegate tasks and monitor completion. Instead of verbally telling five different people what to do (and possibly forgetting something), you can rely on the checklist to communicate those expectations.

Managers can quickly review the checklist at end of day to see if everything was signed off, which areas had issues, etc. It’s a quick visual report of how well your team is adhering to protocols.

This not only saves time but also helps in scheduling (you can plan specific times for checklist tasks) and ensures continuity. If one manager is off, another can step in, and the checklist guides them on what to verify that day.

Cost-savings and legal protection

Perhaps one of the biggest benefits, though often overlooked, is that a checklist helps you avoid the costly consequences of non-compliance. Health violations can lead to fines, legal penalties, or even temporary closure of your business. Diligently using a checklist significantly reduces the likelihood of missing a critical requirement and ending up with a failed inspection.

Remember that even a single critical violation (like unsafe food temperatures or a pest infestation) can get your restaurant shut down on the spot until fixed in many jurisdictions. Repeated or egregious violations may incur hefty fines or lawsuits, and in extreme cases, permit revocation.

For example, operating without hot water or with serious pest problems is often met with immediate closure notices and financial penalties. A checklist, used properly, acts as your insurance against these outcomes by keeping you in line with the law day by day.

In the long run, this is hugely cost-saving – it’s far cheaper to spend a few minutes on preventive checks than to pay thousands in fines or lost revenue from a shutdown. Some businesses have sadly learned the hard way that neglecting food safety can even result in litigation (if customers get sick).

Using your checklists and keeping records of them shows “good faith” and due diligence, which can be a critical defense if something ever does go wrong.

Reputation and performance improvement

Consistent use of a health inspection checklist can tangibly improve your inspection scores over time, which boosts your restaurant’s reputation. As an example, consider the case of Chipotle Mexican Grill after their well-publicized food safety incidents in 2015. In response, Chipotle invested heavily in food safety protocols – they introduced rigorous daily checklists and even designated a Food Safety Leader on each shift to review a 13-point HACCP log every day.

These moves, essentially making sure every critical item on their safety checklist was verified constantly, helped Chipotle regain trust. In the years following the outbreaks, the company significantly enhanced its food safety programs and rebounded in both compliance and public perception. This illustrates how a strong checklist system, coupled with training, can lead to remarkable improvements.

On a smaller scale, many independent restaurants have seen similar turnarounds. For instance, a local café that struggled with mediocre health scores adopted a daily health checklist and an internal audit routine and, by the next inspection cycle, they went from a “C” grade to an “A”. The checklist instilled discipline that not only impressed the inspector but also created a cleaner, more efficient workplace.

Such success stories show that investing time in proactive inspections (with checklists) yields better official inspection results. A top health grade or a track record of zero critical violations becomes a selling point to customers (often posted proudly in the window) and spares you the negative press of any “dirty dining” reports. In short, the checklist approach doesn’t just keep you out of trouble; it actively enhances your restaurant’s quality and standing.

How to create a Health Inspection Checklist?

A health inspector usually arrives at the doorstep of your restaurant, clutching a clipboard with a checklist on it.

These checklists contain the specific areas you need to brush up on before an inspection occurs. As such, your checklist must be clear, comprehensive, and complete.

To guide you on how to make a complete health inspection checklist, here is a list of things you have to do:

- Take notes from your previous inspections. If your food business has been around for quite some time, you must have experienced a health inspection before. Draw information from the previous conclusion that the inspector has provided you with and include necessary tasks from it and add it to your checklist.

- Organize items in your checklist. Categorize all items to check based on major classifications such as sanitation, food safety practices, and employee health and hygiene. This will help your in-house team tick off the tasks from the checklist more efficiently.

- Highlight areas you are experiencing difficulties. In some food businesses, there may be high-risk points and key safety issues in your production process that may need extra attention. You can highlight these points to give emphasis and allow employees to ensure that they are correctly accomplished.

- Customize your checklist. As we have mentioned, some food businesses will have tasks or points specific to them. An example would be the case of a food production company. A checklist for such a business may include checking dedicated handwashing areas, kitchen zones, and preparation booths.

You can use our free Health Inspection Checklist template. All you have to do is customize the provided template by adding specific areas and practices in your operation and printing it accordingly. If you want a more intuitive solution, use a Food Safety Management System.

How to prepare for a restaurant health inspection?

Health inspections are standard evaluations conducted by authorized food safety agencies. The results of an inspection are a reflection of how well your team commits to food safety and serving quality food products.

Here are a few steps that you can do to prepare for a health inspection:

- Know the regulations. Your entire team must know food regulations specific to your location and business type.

- Conduct in-house inspections. In-house inspections are based on previous health evaluations conducted by authorized agencies. Use an established restaurant health inspection checklist. This step promotes accountability among team members.

- Train your team. Food safety training is a critical part if you want to ace a health inspection. Food handlers must be not only knowledgeable but also skilled when it comes to the proper handling of food products.

- Maintain proper documentation. Keep all necessary records and documentation in order. This includes monitoring forms, licenses, permits, food safety certifications, cleaning schedules, and food temperature logs.

- Review employee hygiene. As a manager, it is your task to communicate and evaluate proper hygiene among food handlers. Emphasize the importance of personal hygiene among your staff. Enforce proper handwashing, the use of gloves, and appropriate work attire.

- Address previous violations. A health inspector will provide you with the results of an inspection through a comprehensive health inspection report. In case of violations, you will be given enough time to comply. Use the evaluation pointers given to your by the inspector to improve your operations.

- Stay Calm and Cooperate. On the inspection day, remain calm and cooperate with the health inspector. Answer their questions truthfully and provide any requested documentation promptly.

Although health inspections can be scary at times, they are performed to help you serve safe foods. During an inspection, the health inspector must see that your team is well-formed and prepared. Food business teams are encouraged to consider health department inspections a learning and accountability system for better food service.

By proactively preparing for a health inspection, you increase the likelihood of receiving a favorable review, maintaining compliance with regulations, and ensuring the health and safety of your customers and staff.

Health inspection checklist for food trucks

Health inspections for food trucks and other mobile food units follow the same food safety principles as restaurant inspections but include additional operational considerations due to mobility and limited space.

A health inspection checklist for food trucks commonly includes checks related to:

-

Food preparation and storage inside mobile units

-

Temperature control during transport and service

-

Approved commissary use and documentation

-

Potable water supply and wastewater disposal

-

Equipment stability, ventilation, and power sources

Because requirements for mobile food units may differ from fixed establishments, food truck operators should ensure their checklist reflects local mobile food regulations in addition to general food safety standards.

Using checklists for inspection preparation

Health inspection checklists are designed to support food safety management, not replace regulatory guidance or official inspections. Regular self-inspections using a checklist can help identify gaps, reinforce safe practices, and improve overall inspection readiness.

How does the health inspection grading scale work?

A health inspection grading scale is a system used to indicate the result of a recently concluded evaluation of a food business facility in terms of compliance with safety regulations.

The grading scale varies by region or jurisdiction, but the general idea is to provide the public with an easy-to-understand rating that indicates the establishment's overall compliance with health and safety standards.

Grading scales can be represented in different ways:

- Numerical scale: This scale often ranges from 1 to 100, where higher scores mean better compliance.

- Letter-grading scale: Some agencies use letters, such as A, B, C, and D, with corresponding grade ranges for each letter. The letters can also indicate compliance grades, such as "excellent" or "with minor violation."

- Color-coded system: In some areas, health departments use color-coded placards or stickers to display the inspection grade. Each color may indicate different levels of compliance or status.

- Point system: In certain places, health inspections are scored using a point system, where each violation is assigned a specific number of points based on severity. The total points determine the grade.

Depending on the regulations of an agency, the final evaluation or health inspection score may be required to be displayed in a noticeable location. This regulation aims to help consumers understand how your team takes food safety seriously.

Learn more about how scores affect consumer perception and how digital solutions can help you achieve higher ratings in our detailed case study.

Publicizing the health department rating motivates establishments to maintain high standards and gives customers the confidence that they are dining in a safe and compliant environment.

Why should you digitize your health inspection checklist (and other food safety tasks)?

Going digital with your health inspection checklist can amplify its effectiveness and make life a lot easier. In the modern food industry, many businesses are swapping their clipboards and filing cabinets for tablets and cloud-based apps. Here are some actionable tips on how to digitize your health inspection process:

Scan or upload your paper checklists to the cloud

If you’re currently using paper forms, start by creating digital copies of your checklist. Simply scanning completed checklists into PDF and saving them on a secure cloud storage (like Google Drive, Dropbox, or a restaurant management platform) will ensure you have a backup of all records. This way, nothing gets lost or coffee-stained, and you can retrieve past logs in seconds by date or keyword search. (No more rifling through binders when an inspector asks for last month’s sanitation logs.) Keep a well-organized folder system (e.g., year > month > date) so that any manager can quickly find the needed documents.

Assign a staff member or manager to scan the week’s checklists every Friday, so it becomes routine. Even though this is a simple step, it demonstrates diligence and transparency. Some health departments appreciate when an operator can pull up digital records on the spot.

Use digital checklist apps or software

Scanned PDFs are a start, but the real benefits come from using dedicated digital food safety tools. There are Food Safety Management System (FSMS) software and mobile apps that allow you to recreate your inspection checklist in electronic form.

For example, FoodDocs offers automatically generated digital checklists that you can customize to your operations. With a digital checklist, staff can tick off items on a tablet or smartphone as they complete them. These entries can be time-stamped, and even include photos as evidence (some apps let an employee attach a photo of, say, a cleaned fridge or a thermometer reading).

Going paperless means you’ll never “lose” a record, and it also prevents falsification since the data is recorded in real-time. Using a well-designed app can nip the “pencil-whipping” issue in the bud – if an item is skipped or done late, many systems will flag it.

Most digital solutions will archive all submissions, so preparing for an audit or analyzing trends is far easier than with stacks of paper. You can typically filter or search your data (e.g., check all entries where “No” was marked to see which issues recur most).

Integrate with your existing systems

Look at ways to integrate the digital checklist into tools you already use, such as your POS or scheduling system. Some POS or restaurant management systems have modules or add-ons for task management. For instance, your POS could pop up a reminder for the cashier to do the dining room bathroom check at 2 PM, or for a chef to do a line check before dinner service.

If those systems don’t support it, even setting simple calendar reminders or alarms on a shared device can help ensure the digital checklist gets filled at the right times. The idea is to embed food safety tasks into the daily tech workflow.

Employees might already use a tablet for taking orders or managing tickets. Having the inspection checklist on the same device (maybe as a bookmarked app or an icon on the home screen) can prompt them to complete it.

Integration can also mean that your temperature monitoring devices (if you have smart sensors in coolers) feed data into your digital logs, or your purchasing/inventory system flags if a product recall needs to be added as a checkpoint on your list.

Advanced FSMS platforms allow API integrations where, say, a corrective action triggered in a digital checklist (like recording a fridge at high temperature) can send an alert to managers by email or SMS.

While that level of integration may not be for everyone, even basic linking of systems, such as storing your digital checklists on the same Google Drive that corporate uses or exporting weekly summary reports to email, can streamline your operations.

Take advantage of automation and reminders

One big benefit of digital solutions is automated scheduling and reminders. Set up your digital checklist tool to send notifications to the responsible persons. For example, at 10 AM a phone notification could prompt, “Time to do the mid-morning health check – complete the Opening Checklist now.”

If the task isn’t checked off by a certain time, some systems will escalate it (maybe notify a manager that it’s overdue). These automated nudges ensure that even on busy days, critical food safety checks aren’t forgotten.

Digital systems can often auto-generate tasks when certain criteria are met. If an entry is marked “No” (problem found), the system might create a follow-up task for maintenance or a re-check.

Embracing these features takes a lot of the mental load off managers trying to remember everything. It helps turn the checklist into a living process that runs in the background, rather than a static sheet someone might ignore. Many users report that digitizing their checklists speeds up oversight and response times because they can address issues faster and with less managerial micromanagement.

Ensure data is searchable and backed up

When digitizing, make sure the solution you choose allows you to easily search and analyze your records. One drawback of merely scanning to PDF is that, unless you OCR them, you can’t quickly query the data. A good digital checklist platform will let you filter by date, category, or even specific question responses.

This means you can quickly answer questions like, “How often in the past month did we have sanitizer concentration issues?” or “Show me all notes related to pest sightings.”

Having searchable, well-organized digital data can be a lifesaver for demonstrating compliance. If an inspector or auditor asks for proof of something (say, your last time you cleaned the grease trap), a quick database search beats flipping through a logbook.

Additionally, always ensure your data is backed up (most cloud-based systems do this automatically). Redundancy is key. If a device is lost or there’s a network outage, you should still be able to access your records from another login or have exports saved.

The peace of mind from knowing your food safety history is safe and accessible is a huge advantage of digital systems. It also aids legal compliance, as you can readily produce required records and even forestall potential litigation or fines by demonstrating your diligence.

Use analytics to improve

Once your checklists are digital, you unlock the power of analytics. Review the collected data periodically using whatever reporting tools are available. You might discover patterns, e.g., one location has more issues than others in a chain, or certain days of the week have more missed items (maybe when a particular manager isn’t on duty).

You can use these insights to improve operations, target training, or adjust staffing. Essentially, the data gathered can guide you to strengthen your HACCP plan or risk management by pinpointing where things tend to go wrong.

Some digital solutions will even provide dashboards or trend reports. This transforms the checklist from a compliance task into a proactive management tool. It’s not just about avoiding violations but continuously upping your game in food safety.

How to ace a health inspection using FoodDocs

We understand the importance of acing an official health inspection and possibly getting poor health inspection results. It can make or break your food business's reputation.

Our food safety experts at FoodDocs have devised a way to help you stay compliant with all the most important food safety regulations and health inspection activities with our digital Food Safety Management and avoid health inspection violations. With this solution, you will no longer need paper forms for your health inspections.

Health inspection checklist to ensure compliance with food safety principles

You can get an automatically generated digital Health Inspection Checklist designed for your food business. These checklists are versatile and can be adapted to your operations by customizing them.

Use this Health Inspection Checklist to ensure that your business is consistently compliant with food safety principles and regulations. With this feature, you can quickly pass an official inspection and get a great score.

Customize the inspection checklist by adding key areas to evaluate. You can choose from a numerical grading system or a done/not done format.

Customizable system to fit your business needs

What makes our software system great is that it can be further customized to fit your operations and accommodate suggestions from inspectors. Once you sign up, our system automatically generates monitoring tasks based on your business profile with the help of artificial intelligence and a machine learning program.

You can improve all monitoring tasks by incorporating your unique operations. You can also upload your own checklists and turn them into digital monitoring tasks.

Step-by-step instructions to help train food handlers

To help food handlers accurately perform food safety practices all the time, our monitoring tasks and checklists feature detailed instructions. Managers can use these instructions to train new food handlers,

Similarly, employees can use the instructions as a reference during operations. Users can upload their own versions of the instructions as images or videos. With this feature, you can ensure that every task in a health inspection checklist is done accurately.

Real-time overview to save time from supervision

Our smart software features a real-time dashboard that gives you a report of the progress of your daily food service operations. This feature will help you focus on which sections of your food safety system your operations are lacking in.

The real-time dashboard can help managers identify which areas are non-compliant and address them promptly. The team can use information from the dashboard to develop better strategies to fulfill health inspection checklist tasks.

Switching your food safety management system has never been this easy! As promised, it will only take you an average of 15 minutes to answer our questions and confirm your automatically generated FSMS.

Ace all health inspections and impress your local food safety inspector with the help of our smart software. Make all your monitoring activities easier and more accessible with FoodDocs.

Frequently Asked Questions (FAQs)

What is a point of focus during a health inspection?

Health inspectors focus on key areas during a health inspection, including food safety, hygiene practices, facility sanitation, equipment maintenance, pest control, and compliance with health regulations.

What do health inspectors look for?

Health inspectors primarily look for proper food handling and storage practices, including temperature control and avoiding cross-contamination. They assess the cleanliness and sanitation of the facility, employee hygiene and handwashing practices, proper equipment maintenance, and the presence of pests or signs of infestation. Inspectors also check for accurate documentation and compliance with relevant health and safety regulations.

How to pass a health inspection audit for a restaurant checklist

To pass a health inspection for a restaurant, implement a rigorous checklist that covers all areas inspected by health officials. You can ensure compliance with food safety regulations by implementing a comprehensive food safety management system.