FREEZER ORGANIZATION CHART | FREE DOWNLOAD

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

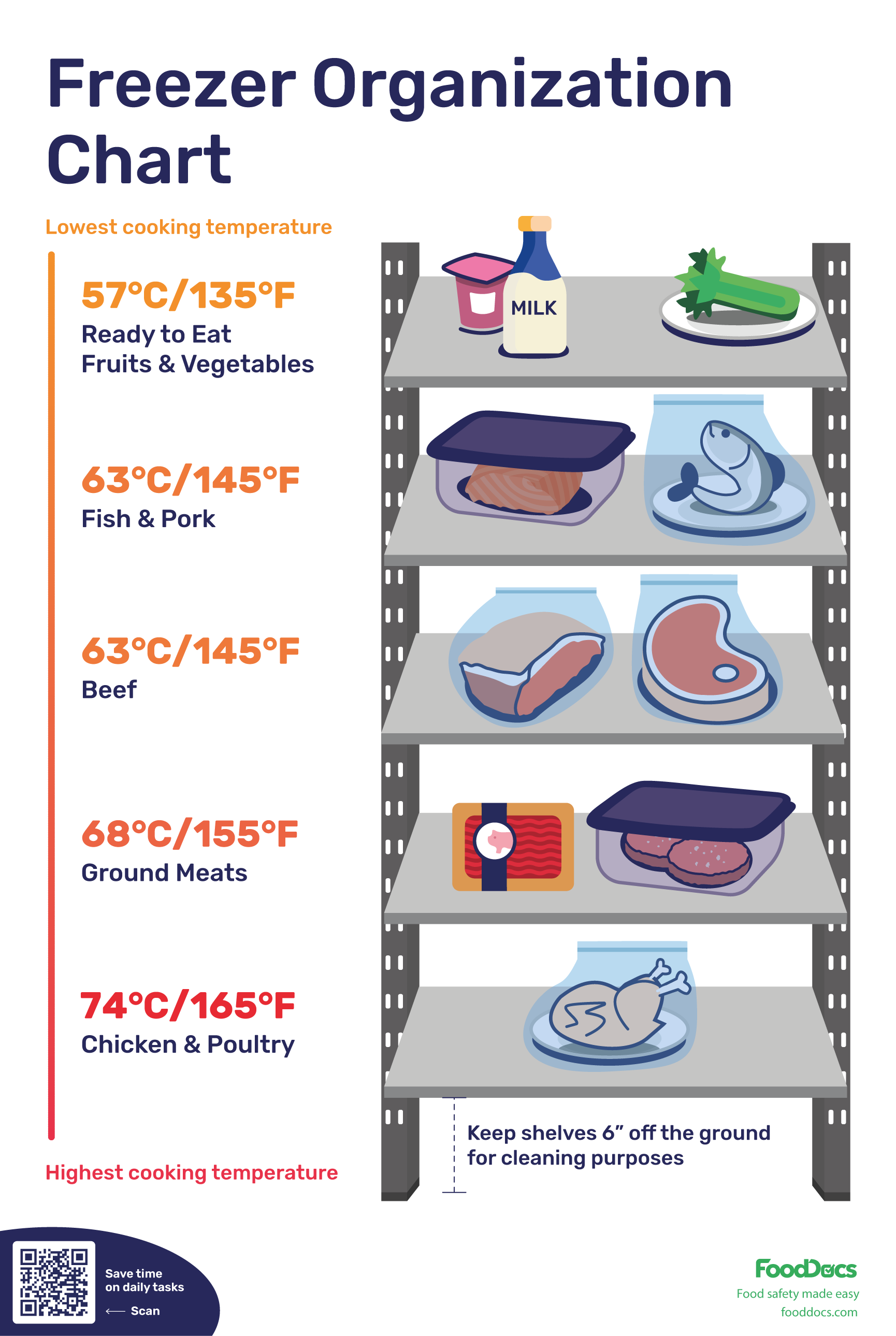

Maintaining proper freezer organization is about much more than just convenience. It’s crucial for ensuring food safety, quality, and compliance with health standards.

A freezer organization chart offers an efficient way to manage cold storage, minimize risks of cross-contamination, and optimize the use of space in busy commercial kitchens and food production facilities.

Interested in our other free cold food storage charts and posters? Check these out:

- Freezer temperature chart

- Cold food storage rules

- Cold holding food temperatures

- Fridge organization chart

- Fridge temperature chart

- Fridge layout food safety poster

- Vacuum-sealed food shelf life chart

- How long can a fridge and freezer go without power?

- Proper freezer storage times chart

Whether it's the printable freezer storage chart or any of these other printable posters, download them for use in your kitchens to keep team members sharp!

What is a freezer organization chart?

A freezer organization chart is a visual or written plan that designates specific zones within a freezer for different types of food. In other words, a freezer map. It helps kitchen staff quickly understand where to store raw meats, ready-to-eat items, bulk ingredients, and more, based on food safety protocols.

This system is particularly important for food establishments that heavily use freezers, such as restaurants and food manufacturing plants.

Unlike a fridge organization chart, which deals with perishables stored at higher temperatures, a freezer chart focuses on managing long-term food storage. The chart promotes proper food handling, reduces the risk of freezer burn, and ensures that older freezer inventory is used first.

Who needs a printable freezer storage chart?

Any commercial operation that relies on frozen food storage should implement a freezer organization chart. It's simply a proper food storage practice. This includes:

- Food manufacturing plants: In facilities producing frozen meals, ingredients, or desserts, freezer organization helps ensure food safety compliance with health regulations and streamlines production processes.

- Restaurants and cafés: Where freezer space is shared by multiple employees, a clear organization chart prevents errors like improper storage of raw and ready-to-eat foods.

- Catering services: When dealing with large volumes of frozen items, it’s critical to keep everything organized to avoid contamination and food waste.

Why is freezer organization important?

Freezer organization, along with proper temperatures, plays a critical role in maintaining food safety and optimizing kitchen workflows. Here's why it matters...

Freezer organization prevents cross-contamination. In a commercial kitchen, improper storage of raw meats alongside ready-to-eat foods can cause serious contamination risks and even lead to foodborne illnesses. Proper freezer organization helps mitigate these risks by creating clearly defined storage zones.

It also preserves food quality. Organizing your freezer prevents freezer burn, which occurs when food is exposed to air. Freezer burn not only affects taste and texture but can also result in food being thrown away, leading to unnecessary waste.

Lastly, proper freezer organization improves efficiency. In a fast-paced kitchen environment, having organized freezers allows staff to find ingredients quickly, reducing downtime and improving overall kitchen efficiency.

What are the benefits of a freezer organization chart?

Incorporating a freezer organization chart into your kitchen workflow offers four key benefits:

- Food safety compliance: Proper food storage is key to meeting food safety regulations. A well-implemented chart helps ensure that all freezer items are stored according to the highest safety standards.

- Reduced food waste: Keeping track of items’ placement and ensuring older stock is used first (First In, First Out), will help reduce the chances of spoiled or forgotten food.

- Streamlined operations: Clear food labeling and designated storage zones mean that food handlers can locate ingredients faster, leading to smoother kitchen food safety operations during busy periods.

- Minimized risk of contamination: Separating raw meats from other food categories reduces the risk of growth of bacteria and contamination that can result from improperly stored items.

3 Best practices for freezer organization

Alongside your freezer organization chart, follow these best practices to maintain food safety and quality:

- Label and date all items: Clearly label each item with the date it was frozen and its use-by date. This helps staff or family members identify older items and reduces the risk of using spoiled food.

- Avoid overpacking: A deep freezer (or any freezer for that matter) that’s too full won’t circulate cold air properly, leading to uneven freezing and potential safety issues. Leave enough space between items to allow for proper airflow.

- Regularly inspect and clean: Check your freezer weekly for any expired or improperly stored items. Failing to do so could lead to unnecessary foodborne illness. Clean any spills or frost build-up to maintain a safe and organized space.

Essential sections for a freezer organization chart

To get the most out of your freezer, use a freezer organization chart to define storage zones based on food type and safety priorities. Here's a breakdown of key sections you should include:

Top shelves: ready-to-eat foods

Place pre-cooked meals, frozen vegetables, and ready-to-eat food items on the top shelves. These foods are less likely to drip or cross-contaminate other items. Organizing them at eye level also makes it easier to grab what you need quickly, especially during busy service times in a commercial kitchen.

Middle shelves: cooked foods or semi-cooked food items

Foods that require minimal further cooking like frozen entrees or partially prepared meals belong on the middle shelves. Keep these separate from raw food ingredients to ensure no unintended cross-contact happens.

Bottom shelves: raw meats and seafood

The bottom shelves should always be reserved for raw foods such as frozen meats, poultry, and seafood. Even in freezing temperatures, before any type of meat is frozen, raw juices can drip and contaminate other foods if they are not stored properly. Use leak-proof containers or well-wrapped packages to minimize this risk.

Freezer drawers: bulk ingredients and long-term storage

Bulk items like frozen grains, doughs, or larger cuts of meat can go in the lower drawers or deep freezer compartments. This section is ideal for long-term storage, where products will be kept for longer periods without frequent access.

Door storage space: not recommended for perishable items

This is more relevant for home freezers. Many commercial freezers will not have door compartments as they're designed to always keep frozen food inside (i.e., if you open the freezer door at home, food is technically outside of the freezer).

The freezer door experiences the most temperature fluctuations, making it less suitable for perishable foods. Instead, store non-essential items like ice packs, butter, or unopened spices that won’t suffer from slight temperature changes.

How to create a freezer organization chart

Creating a freezer organization chart for your food establishment's commercial kitchen doesn’t have to be complex. Follow these steps to design an effective system:

-

Map your freezer zones: Start by identifying different sections of your freezer, including top shelves, middle shelves, bottom shelves, and drawers. Assign each section based on the type of food being stored (e.g., raw meats on the bottom, ready-to-eat foods on top).

-

Categorize food by safety levels: As a rule of thumb, always store raw meats, poultry, and seafood on the lowest shelves to prevent juices from dripping onto other foods. Ready-to-eat and pre-cooked items should be placed higher up.

-

Label shelves and items: Label both the freezer sections and the individual items. Include information like the date of freezing food and the use-by date to track food freshness and ensure proper stock rotation.

-

Implement First In, First Out (FIFO): Use the FIFO method to keep track of stock. This way, older items are used before newer ones, reducing waste and ensuring product freshness.

-

Train your staff: A freezer organization chart is only effective if staff members are trained on its importance and proper use. Regularly review procedures to ensure food safety compliance and understanding. (Use this Food Handlers Test Questions and Answers PDF!)

A well-planned freezer organization chart is essential for maintaining food safety, operational efficiency, and compliance in any commercial kitchen or production facility.

Simplify and streamline freezer temperature monitoring and cold storage with FoodDocs

FoodDocs is a Food Safety Management software that makes food safety easy by digitizing daily monitoring and traceability tasks. Try it free for 14 days!

Save time on logging freezer temperatures and similar daily tasks

At the beginning of your food safety monitoring system setup, you can choose to use automatically generated logs and get set up fast! You can also create custom temperature logs based on your business's specific freezer conditions.

There are two features that especially make life easier for team members who are responsible for logging temperatures:

- Smart notifications: Team members responsible for food safety tasks such as logging freezer temperatures during a shift will get timely notifications so they never miss another log again.

- Corrective action prompts: If a team member inputs a freezer temperature that's outside of your pre-defined acceptable range, the FoodDocs mobile app will immediately prompt them with corrective action instructions according to your food business's standards.

If your business uses freezer temperature sensors, FoodDocs also sensor integration partners and an API that can help automate the freezer temp monitoring process.

Know your business's food safety compliance status at any time with a real-time overview

Whether you're on-site or remote, the real-time overview dashboard offers a high-level view of each business unit's or department's food safety task completion.

This is a perfect tool for Supervisors or Food Safety/Quality Managers who can easily spot non-conformities and quickly address them before they become food safety incidents.

Our digital food safety system's Verification features also gives you the option to set up monitoring food safety tasks that always need to be verified once team members complete their entries. This feature is essential for food establishments that hold their food safety operation to very high standards.