Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Become a food-freezing pro that your business can depend on.

Freezing food plays a critical role in the food industry, particularly for those working in commercial kitchens, restaurants, and food production. It helps preserve food, prevent waste, and ensure that food remains safe for consumption.

Whether you're managing a large kitchen or simply preparing meals at home, understanding the ins and outs of freezing food is key to keeping things running smoothly and safely.

If shipping food, pay careful attention to proper packaging, required shipping duration, food-safe labeling and regulations (e.g., if using dry ice)

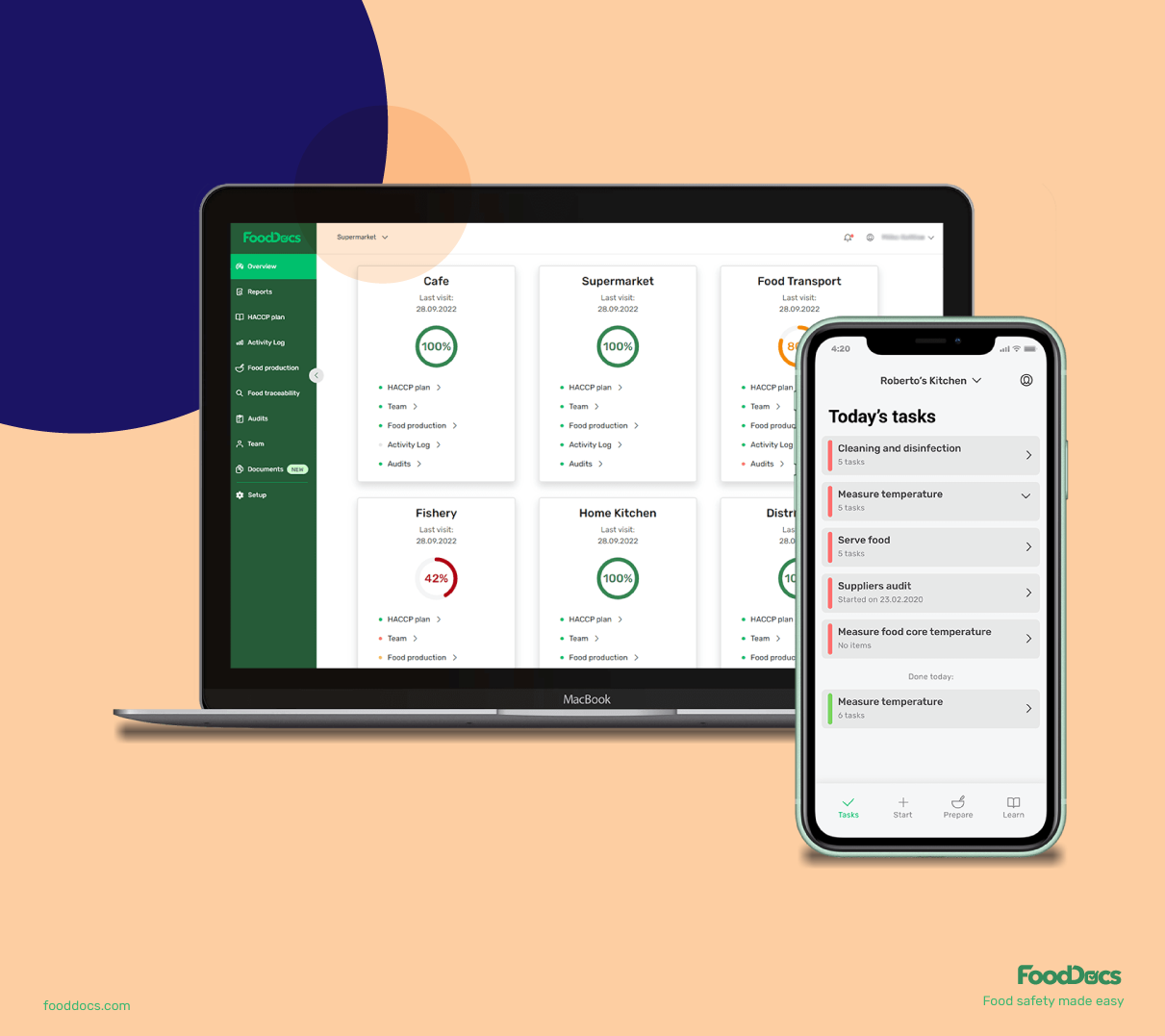

FoodDocs is an easy-to-use Food Safety Management software that helps businesses with food safety monitoring tasks such as logging freezer temperatures more consistently, accurately, and quickly.

Freezing food slows down the growth of harmful bacteria and mold, keeping food fresh for extended periods of time. It's one of the most effective ways to preserve the flavor, texture, and nutritional value of food without compromising safety.

Freezing provides multiple benefits:

Freezing extends the life of food products far beyond their natural expiration dates. For food businesses, this means fewer instances of spoilage, lower costs due to waste, and the ability to purchase products in bulk.

When teams freeze food properly, they can create more flexibility in their inventory and better meet demand without constantly worrying about restocking.

Food waste is a major issue in both home kitchens and commercial environments. Freezing surplus food allows businesses to save product that would otherwise go to waste, especially during off-peak seasons or when there’s overproduction.

This is crucial for cutting costs and maintaining sustainability practices, a growing concern for many consumers and regulatory bodies alike.

Proper freezing halts bacterial growth, keeping food safe for months. It also preserves taste, texture, and nutritional value, which is particularly important in restaurants and food production where food quality affects customer satisfaction.

Ensuring that frozen food remains high-quality can differentiate a business from its competitors, making proper freezing techniques a vital part of any operation.

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

Freezing food does not kill bacteria; instead, it simply prevents bacteria from growing while the food remains frozen. As soon as the food is thawed, bacteria can become active again.

According to the USDA Food Safety and Inspection Service (FSIS), “While freezing does not kill most bacteria, it does stop bacteria from growing.” This means that businesses should handle thawed food as carefully as they would fresh food to avoid contamination.

The FSIS also highlights that proper freezing temperatures are key, stating that food should be kept at 0°F (-18°C) or below to ensure safety and longevity.

Different freezing methods offer various benefits:

Flash freezing rapidly reduces the temperature of food using very cold air or liquid. This method is ideal for food businesses like restaurants or catering services where maintaining the food’s texture and freshness is key.

Flash-frozen items are less likely to develop large ice crystals, which can damage food cells and alter texture upon thawing. For busy kitchens, it allows for higher-quality products and less food preparation time before cooking.

In commercial and industrial settings, cryogenic freezing uses liquid nitrogen or carbon dioxide to freeze products at extremely low temperatures in a matter of seconds. This is commonly used for mass production of items like frozen seafood or prepackaged meals.

The main benefit for large food producers is that it allows for bulk freezing without compromising food quality, making it an efficient solution for those managing large-scale food storage.

Slow freezing, often used in home or smaller commercial kitchens, takes longer and allows for the formation of larger ice crystals. While it’s a more economical option, slow freezing can sometimes degrade the quality of food, especially for delicate items like fruits or vegetables.

For small food businesses or chefs working in smaller production kitchens, slow freezing can be acceptable for bulkier products like meat but may not yield the best results for more sensitive frozen ingredients.

Yes, frozen food can go bad if it’s not stored properly or kept for too long. Over time, even frozen food items can develop freezer burn or lose flavor and texture, though they typically remain safe to eat.

Labeling and dating each item is essential for proper inventory management in commercial kitchens. It prevents confusion and ensures a “first in, first out” system, where older items are used before newer ones. This reduces waste and avoids the potential for food to spoil unnoticed at the back of a freezer.

Additionally, clear food labeling ensures compliance with food safety guidelines and facility audits.

Using airtight metal or plastic containers or vacuum-sealed bags for food items can significantly reduce the risk of freezer burn. For food businesses, this means preserving the texture and flavor of items like meat and fish, which are often expensive and sensitive to air exposure.

Using a vacuum sealer or insulated containers will result in well-sealed items that offer extra protection, while maximizing freezer capacity.

By freezing food in portion sizes appropriate for daily use, restaurants and production kitchens can avoid the need to thaw large quantities of food that might go unused. This practice cuts down on waste and ensures that thawed items remain fresh until they’re ready to be used.

Portioning also makes it easier for kitchen staff to handle and use food efficiently during busy service times.

Fluctuating freezer temperatures can lead to partial thawing and refreezing, which can affect food quality and safety. Ensure your freezer is set to 0°F (-18°C) or lower and check it regularly.

Implementing routine freezer checks as part of food safety risk management is key to maintaining compliance and avoiding product spoilage.

Overloading your freezer space can prevent air from circulating properly, causing some items to freeze unevenly or not freeze at all. In a commercial kitchen setting, this can lead to a loss of product or unsafe food.

Aim to leave space between items for optimal airflow, and make use of a freezer organization chart to manage space effectively.

Proper thawing is just as important as proper freezing. Thaw frozen food in a refrigerator or use safe methods like cold water thawing rather than leaving it out at room temperature. This minimizes the risk of bacterial growth, ensuring food stays safe to eat.

Many of those frozen food storage tips are in the context of properly freezing food in-house to reduce the risk of foodborne illnesses. But what about those businesses which need to ship frozen food products? Keep scrolling to find out.

Shipping frozen food requires meticulous planning to ensure that the products remain within the correct temperature range throughout transit.

Different types of frozen foods, such as perishable goods like meats and seafood or non-perishable frozen items like pre-packaged snacks, require slightly different handling procedures. Let’s break it down:

For perishable frozen items (e.g., meat, seafood, and dairy products), maintaining a temperature below freezing is crucial to prevent spoilage during shipping. Using specialized packaging and selecting the right shipping service are key to ensuring that the food arrives safely.

Proper packaging: You’ll need insulated shipping containers or coolers with adequate thickness to maintain temperature for the duration of the shipment. Materials like Styrofoam (i.e., insulated foam containers) or thermal bubble wrap work well to keep cold air in and prevent external heat from entering. Pack the food with dry ice or frozen gel packs, depending on the shipping duration. Dry ice is particularly useful for maintaining temperatures below freezing, but it must be handled carefully, as it is a hazardous material.

Shipping duration: Shipping perishables should be done via overnight or two-day shipping to minimize the risk of temperature fluctuations. Companies like FedEx and UPS offer services designed specifically for frozen or refrigerated goods. For example, according to FedEx’s guidelines, using FedEx Priority Overnight or FedEx First Overnight ensures the food reaches its destination while remaining frozen. UPS recommends its Next Day Air service for perishable items to minimize transit time and ensure delivery during the day to prevent spoilage.

Labeling: Improper packaging includes improper or missing labels. Clearly mark the package with labels like “Perishable – Keep Frozen” to alert handlers. This ensures proper care during transit and storage until delivery.

Dry ice regulations: If you’re shipping with dry ice, you must follow shipping carrier guidelines for hazardous materials. FedEx allows shipments with up to 5.5 pounds of dry ice without special paperwork, while UPS requires you to mark packages containing dry ice and indicate the amount being used.

Shipping perishable frozen foods involves careful consideration of packaging, shipping speed, and cooling materials. Choosing the right service and following specific shipping guidelines ensures that your business can deliver frozen food in perfect condition and minimize the risk of spoilage or quality loss.

Compared gel packs and dry ice, it's clear why frozen cubes of ice, conventional ice packs, or thermal liners are inferior methods for shipping frozen food.

We hope the comparison table below helps businesses choose the most effective method depending on the types of frozen food their working and regulations they need to stay compliant with:

| Cooling method | Pros | Cons | Best for |

|---|---|---|---|

| Gel packs |

Safe and non-hazardous Reusable and less expensive Keeps food cool for up to 48 hours |

Only maintains cold temperature slightly below freezing Heavier than dry ice, increasing shipping costs |

Short-duration shipping Non-perishable frozen items Items that need to stay cold, not frozen |

| Dry ice |

Maintains sub-zero temperatures Excellent for keeping food completely frozen Lightweight compared to gel packs |

Hazardous material requiring special handling Dissipates over time (usually within 24-48 hours) Strict carrier regulations |

Perishable foods (frozen meats and seafood) Long-distance or international shipping |

| Regular ice | Readily available and inexpensive |

Melts quickly, causing leakage Only keeps items cold, not frozen Increases weight and potential for damage |

Temporary cooling Local shipments |

| Insulated thermal liners |

Lightweight and reusable Prevents external heat from entering the package |

Does not actively cool, only slows temperature change Requires additional cooling methods for long periods |

Supplementing gel packs or dry ice Short shipping distances with minimal temperature fluctuations |

In short:

There are even large shipment containers for items such as food or pharmaceutical goods. For example, the va-Q-tainer and Envirotainer RKN t2 which aim to provide larger businesses with tools to ship frozen and chilled products safely.

Between properly storing frozen food items and knowing how to ship them so that no one gets anything like food poisoning, managing food safety is challenging. Especially if your food safety system is paper-based.

FoodDocs' digital Food Safety Management System makes food safety easy by digitizing daily monitoring and traceability tasks. Try it free for 14 days!

During the Monitoring system setup, you can use automatically generated logs to get set up fast as well as create custom temperature logs based on your business's specific freezers and freezer conditions.

Between smart notifications and corrective action prompts in the FoodDocs mobile app, your team will log freezer temperatures with far less human error. How?

If your business uses freezer temperature sensors, FoodDocs also sensor integration partners and an API that can help automate the freezer temp monitoring process.

The real-time overview dashboard will be a key part of the Supervisor, Food Safety, or Quality Manager's day. It offers a high-level view of each business unit's or department's food safety compliance.

That way, you can easily spot non-conformities and quickly address them before they become food safety incidents.

Our digital food safety system's Verification features also gives you the option to set up monitoring food safety tasks that always need to be verified once team members complete their entries. This feature is essential for food establishments that hold their food safety operation to very high standards.

If you're wondering, "Why is food freezing in my fridge?" there could be a few factors at play, such as temperature settings being too low or blocked vents inside the fridge. It’s common in busy kitchens when the refrigerator is overfilled, preventing air from circulating properly.

Always freeze food before it spoils, and make sure it’s packed in airtight containers to avoid freezer burn.

Avoid freezing foods with high moisture content like lettuce, cucumbers, and raw potatoes, as they become mushy when thawed.

Yes, freezing cooked food is perfectly healthy as long as it’s done correctly—cool it first and use appropriate containers.

Properly stored, most foods can last 3–12 months in the freezer, depending on the type of food.

Bacteria can survive freezing but remain inactive. Once thawed, they can become active again, so handle with care.

Freezing doesn’t actually kill bacteria; it only pauses their growth.

No, freezing food such as raw meat does not kill bacteria. It halts their growth but doesn’t eliminate them.

Freezing helps preserve nutrients, reduces waste, and saves money by allowing bulk purchases without spoilage.

No, putting hot food directly in the freezer can raise the temperature inside, leading to other foods defrosting or spoiling. Always let food cool first.

One risk is freezer burn, which happens when food is exposed to air, causing dry spots and loss of quality.

Freezing food for seven days at 0°F or below can help eliminate parasites in foods such as fish, according to FDA guidelines.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...