Why Is Food Safety Important In Healthcare? Healthcare Leaders Guide

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Master restaurant sanitizing with clear steps for kitchens and dining areas.

Maintaining a spotless, sanitary environment in a restaurant is critical for safety, compliance, and your business’s reputation. In the United States alone, an estimated 48 million cases of foodborne illness happen each year. Often, these get traced back to lapses in cleanliness. A single outbreak or failed health inspection can tarnish everything you've built and put customers at risk.

Consistent sanitizing, by contrast, protects your patrons' health and keeps your business aligned with health regulations. Restaurant managers, and chefs need to treat sanitizing as a top priority to prevent cross-contamination, avoid foodborne pathogens, and ensure diners have a safe experience. Because mastering restaurant sanitization is foundational to running a successful food service operation.

While people often relate sanitizing with hands, front- and back-of-house restaurant sanitation also includes high-touch surfaces (sanitized many times per day), food-contact equipment and utensils, equipment controls and touchpoints, cleaning tools, and restroom-related surfaces.

To properly sanitize, you must clean first (soap plus water), rinse, then apply sanitizer. Never skip or reverse those steps.

The most common sanitizing methods in restaurants are chlorine-based solutions and quaternary ammonium compounds, plus heat from dishwashers.

Any food-contact surface must be cleaned and sanitized between uses, especially when switching from raw proteins to ready-to-eat foods.

For utensils washed by hand, you should use the three-sink method: wash, rinse, then soak in sanitizer and let them air dry.

In front-of-house areas, sanitize tables, chairs, menus, condiment containers, and all high-touch surfaces after each use or daily at minimum.

A structured sanitizing checklist with daily, weekly, and monthly tasks helps ensure nothing gets overlooked, even during busy shifts.

Regular deep-cleaning of harder-to-reach equipment like hoods, grease traps, and refrigeration interiors prevents microbial buildup over time.

During health inspections, inspectors will check that you use correct sanitizer concentrations, test strips, and documented cleaning logs.

A well-trained team that understands why sanitizing matters and how to do it right is your best defense against foodborne risk.

Digital food safety tools like FoodDocs that send reminders, train your team, and track completion, can streamline sanitation accountability.

Cleaning means removing visible dirt, food debris, and grease from surfaces, usually with soap or detergent and water. Sanitizing, on the other hand, means using chemicals or heat to kill the germs and bacteria on a surface after it's been cleaned.

Research shows that even surfaces that look clean to the eye can harbor millions of microbes if not properly sanitized. For this reason, all food-contact surfaces must be washed, rinsed, and then sanitized after each use.

Some key sanitizing best practices include:

Also remember that cleaners and sanitizers aren't the same product. Don't mix them together, as this can be dangerous and reduce effectiveness. Understanding these differences and rules with help your team ensure that cleaning and sanitizing are both done properly in the correct order.

Most restaurants rely on chemical sanitizers because they're effective, inexpensive, and easy to use.

Chlorine-based solutions, basically bleach and water, are the most common. They're often mixed to around 50 to 100 ppm for dishes or 100 to 200 ppm for surface wipes. Quaternary ammonium compounds, called quats, are another widely used option, especially in spray bottles or sanitizer buckets for wiping down prep areas.

Heat is also used in some cases. Commercial dishwashers that reach 171°F in the rinse cycle sanitize without chemicals. Each method is acceptable, provided it meets local health code requirements and is used correctly.

Employees’ hands are just the starting point of restaurant sanitizing. The following areas and items are also important to have clear sanitation instructions for:

Multiple staff touch these surfaces frequently, which act as cross-contamination bridges between raw food, clean food, and staff (and are easy to forget during a busy service).

These must be cleaned and sanitized between tasks, not just at the end of the day, because the surfaces have direct contact with food. This makes them a primary focus during inspections.

These are easy to overlook because they don’t touch food directly.

Dirty cleaning tools spread contamination instead of removing it.

These are among the highest-risk contamination points in the entire facility and, as a result, require strict and frequent sanitizing.

Sanitation can be both time-based and/or event-driven. Here are a few of the most common restaurant activities that should trigger sanitation:

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

Sanitizing the kitchen involves systematic, thorough cleaning followed by targeted sanitizing of all food-contact surfaces, equipment, and utensils. A kitchen sees constant activity, so a "clean as you go" approach combined with scheduled restaurant deep cleanings is essential. Here's how to approach sanitizing your kitchen step by step.

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

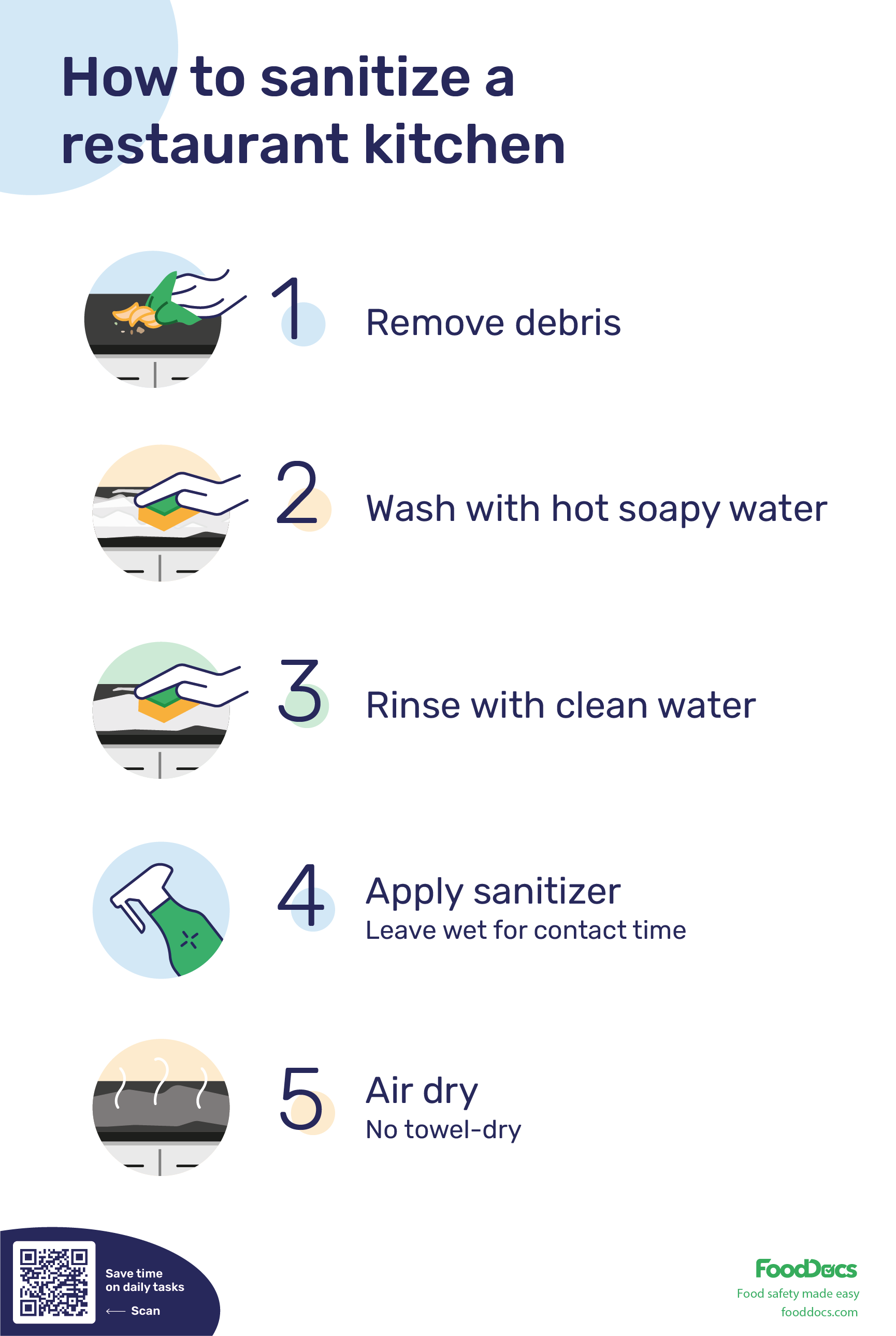

For any food prep counter, cutting board, or equipment surface, use this procedure:

Teams should perform these steps throughout the day on critical surfaces and especially after handling raw meat or allergens to prevent cross-contamination. Sanitizing isn't just for end-of-day. Make it routine between tasks. For example, a chopping board used for raw poultry must be cleaned and sanitized before using it for vegetables or another dish.

Dishes, cookware, and utensils must also be sanitized after cleaning. And, on the flip side, utensils should not be dried with a dish towel due to the risk of cross-contamination and bacterial growth.

In many kitchens, a commercial dishwasher handles this using either high heat or chemical sanitizing in the final rinse. If washing dishes by hand, the three-compartment sink method is recommended: wash in the first sink, rinse in the second, then soak in a sanitizer solution in the third sink, followed by air-drying.

For a chlorine bleach sanitizing dip, a typical concentration is 50 to 100 ppm of chlorine, made by a small amount of bleach in water, and the items should remain submerged for at least 1 minute before drying. Always let dishes and tools air-dry. Don't towel-dry them after sanitization.

Large kitchen equipment and stationary appliances like stoves, grills, fryers, and mixers also need regular cleaning and sanitizing. Each night, after service, equipment should be cooled, then broken down and cleaned of all food residues. Wipe down equipment exteriors with a food-safe degreaser, then sanitize surfaces that directly contact food.

Restaurant hood filters, range tops, and griddle surfaces, for example, should be cleaned and sanitized daily or as frequently as used. Kitchen sinks and refrigeration units, including shelves and door handles, likewise require sanitizing as part of the routine.

Many appliances have specific cleaning procedures. Always follow manufacturer guidelines, and include those tasks in your cleaning schedule.

To ensure no area gets overlooked, it's helpful to use a checklist for kitchen sanitation tasks. Below is an example of key back-of-house daily cleaning and sanitizing tasks that should be on your list:

In addition to these daily tasks, schedule deep-cleaning for certain equipment weekly or monthly. For example, each week you might de-scale faucets and sinks, boil out the deep fryer, run a cleaning cycle on the ice machine, and thoroughly clean refrigeration units. Ventilation hoods and grease traps might be serviced monthly. By adhering to a consistent cleaning schedule, you'll minimize the risk of bacteria buildup and ensure your kitchen stays inspection-ready.

Customers directly see and experience the front-of-house cleanliness, so sanitizing here is just as important. Dining rooms, service areas, and restrooms have many high-touch surfaces that can spread germs. Key areas to focus on include tables, chairs, menus, countertops, door handles, and restroom facilities.

During service, tables and chair arms and backs should be sanitized after each party finishes dining. Train your staff to wipe down the table thoroughly with a food-safe sanitizer before resetting it for the next guest. Don't forget chair backs or booth seats where people touch. If you use reusable menus or placemats, these need to be cleaned and sanitized daily, or switch to single-use or digital menus. Condiment bottles, salt and pepper shakers, and table caddies are handled by every guest. These should be wiped and sanitized routinely, ideally between each customer or at least daily.

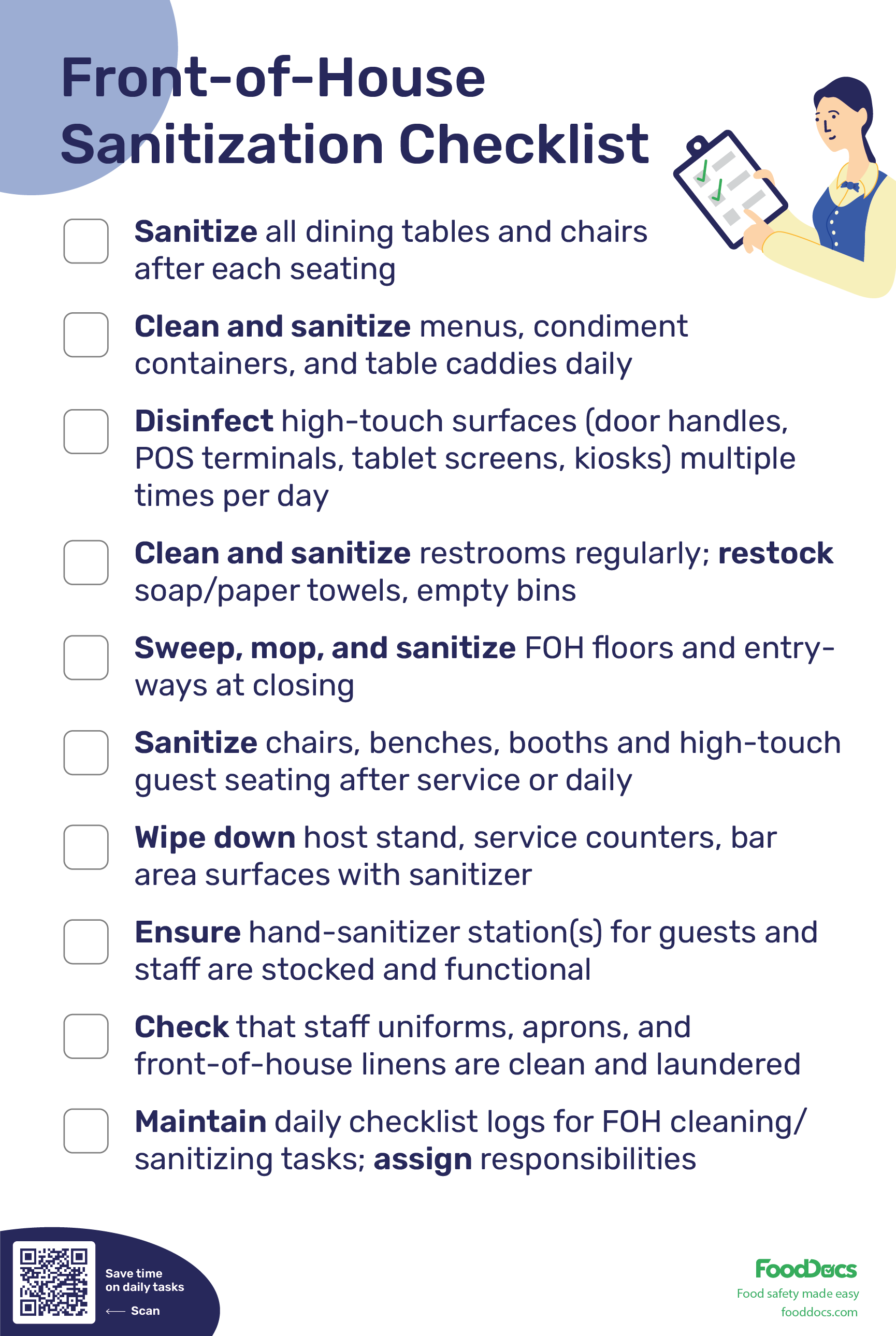

Here's an example front-of-house daily sanitizing checklist with essential tasks:

In the bar area or self-service stations, apply similar diligence. Sanitize the bar top and stools, beverage dispenser nozzles, coffee station surfaces, etc., on a routine schedule. Frequent sanitation of customer-facing areas not only keeps people safe but also reassures guests that your establishment is hygienic.

Don't forget hand hygiene for everyone in the front of house. Consider placing hand sanitizing stations at the entrance and other convenient spots for customers to use. Touch-free hand sanitizer dispensers in the lobby or near the restroom encourage guests to sanitize their hands, adding an extra layer of protection. Likewise, make sure hosts, servers, and bussers wash their hands frequently and use hand sanitizer, especially after clearing tables or handling payments. A culture of cleanliness should extend to every employee and patron interaction.

A sanitizing station is a designated area or setup that provides staff with easy access to sanitizing solutions and tools. Most kitchens keep sanitizer buckets with cloths at each prep station, so workers can quickly wipe down surfaces during shifts.

The sanitizer solution should be at the correct concentration, checked with test strips, and replaced often throughout the day to remain effective. In the dining area, some restaurants set up sanitizing stations with hand sanitizer dispensers for guests, especially near entrances and restrooms.

Having clearly marked sanitizing stations ensures staff and customers always have the means to reduce germs at the point of contact.

Every food safety leader needs to have an overview of the sanitizing checklists because, if left unchecked, your patrons can get sick and inspections can fail. This problem becomes an even bigger one when there are several locations and big teams.

The most effective way to ensure all cleaning and sanitizing tasks get done consistently is to implement an ideally digital checklist and cleaning schedule. Also, let's add that that's why usually bigger companies turn to digital solutions to save time on supervision - instead of driving from one location to another, they have an instant overview.

Breaking tasks down by frequency, like after each use, daily, weekly, or monthly, and assigning responsibility to specific staff members will keep your team organized and accountable.

Many restaurants post daily cleaning checklists in visible areas of the kitchen to be checked off as tasks are completed. Great establishments are increasingly using digital monitoring checklists that remind your team to fill checklists on time, are faster to fill and come with a completed timestamp perfect for recordkeeping.

Key elements of a sanitizing schedule include:

Maintaining structured daily, weekly, and monthly cleaning checklists, and training your staff in these sanitation routines, is key to systematically staying on top of health and safety compliance. Managers or shift supervisors should monitor these checklists and perform walkthroughs. This promotes accountability.

And if you have a health inspection coming up, your records of completed cleaning schedules and SOPs can demonstrate your diligence. In fact, keeping a cleaning log is often part of regulatory compliance.

Finally, remember that written procedures and checklists only work if your staff are well-trained and motivated to follow them. Emphasize training from day one. Every employee should know the proper cleaning and sanitizing procedures for their station. For example, teach kitchen staff exactly how to mix sanitizer and use test strips, and teach front-of-house staff how to correctly sanitize tables without contaminating nearby items.

Reinforce key hygiene practices like frequent hand washing with soap, especially after handling raw foods or using the restroom, for all employees. When your team understands why sanitizing is so important and sees it as non-negotiable, they're more likely to execute the cleaning plan consistently.

Health inspectors pay close attention to how restaurants clean and sanitize.

In the U.S., inspectors check that sanitizer solutions are mixed correctly, that test strips are available, and that surfaces and utensils are sanitized as required. In the UK and Ireland, Environmental Health Officers, or EHOs, expect documented cleaning schedules and evidence that sanitizing is part of daily routines.

Failing to properly sanitize can lead to lower food hygiene ratings, fines, or even closure. Consistent sanitation practices not only protect guests but also demonstrate compliance during inspections, which strengthens your restaurant's reputation.

Mastering restaurant sanitizing is an ongoing commitment, but it's one that pays off through safer food, healthier customers, and a stronger reputation. When you clearly understand cleaning versus sanitizing, implementing rigorous routines with checklists, and possibly utilizing digital tools for support, restaurant managers and staff can create an environment where cleanliness is second nature.

Food safety leaders and executive chefs are increasingly turning to digital solutions to help manage their food safety and sanitation programs. There are now apps and software that can send cleaning task reminders to staff, track completion of sanitizing duties, and store digital records of your hygiene checks. Leveraging such technology can save time up to 10 hours weekly and give managers peace of mind that nothing's slipping through the cracks.

FoodDocs is a digital restaurant food safety platform that enables leaders to achieve monitoring tasks that get done, easily train their staff with step-by-step on-demand instructions, and save time on management.

It allows you to create customized cleaning checklists (or does it for you!), then sends automatic notifications to staff when tasks are due. All tasks are tracked in a real-time dashboard, using a simple traffic-light system to flag any misses. With a tool like this, you can instantly see if the lunchtime sanitizer bucket check or the end-of-day floor mopping was completed on time.

FoodDocs even provides built-in monitoring checks for common cleaning and sanitation Standard Operating Procedures, from equipment cleaning routines to personal hygiene practices, which you can easily customize to your specific restaurant operations with photo and video aids built in.

If managing an ever-growing stack of cleaning checklists and food safety forms feels overwhelming, consider exploring solutions like FoodDocs to help.

You first clean, which means remove visible debris with soap or detergent and water. Then you rinse to wash away soap and loosened soil. Only afterward do you sanitize by applying a chemical or heat method that reduces microbes to safe levels. Skipping or reversing steps weakens effectiveness.

Any food-contact surface like cutting boards, utensils, or slicers must be cleaned and sanitized between uses, especially when switching from raw animal food to ready-to-eat items. If contamination is suspected, re-clean and sanitize immediately.

A reliable multi-step sanitation routine improves consistency. For example:

Always use food-grade sanitizers approved for food-contact surfaces. Never mix different chemicals, like bleach plus ammonia. Prepare fresh sanitizer solutions daily and label them clearly. Use test strips to verify the concentration in ppm. Be aware that cleaners may need rinsing before sanitizing since residual detergent can interfere with sanitizer action.

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...

Boost your retail food safety with essential practices and digital tools to protect customers and your brand. Plus a free Retail Food Safety Leader...