Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

BRCGS is the first ever food safety standards benchmarked by the GFSI organization.

The British Retail Consortium (BRC) is the first-ever standard benchmarked by the Global Food Safety Initiative (GFSI).

The organisation published their Global Standards in 1998 and benchmarked around 22,000 locations globally. The application of the standards exponentially grew from just applying to retail businesses in the UK to a global movement for industries such as food, packaging, and consumer products.

Securing a BRCGS certification is solid proof of a company's commitment to food safety and quality in the industry.

BRC, or British Retail Consortium, is a leading trade association that sets global standards for food safety, quality, and operational criteria across various industries.

BRCGS certification is a globally recognised accreditation that validates a company's commitment to strict standards for food safety, quality, and operational excellence within its respective industry.

Companies involved in food production, packaging, storage, and distribution, as well as those manufacturing consumer products and handling non-food items, benefit from BRCGS certification to demonstrate their commitment to high standards of safety, quality, and operational practices.

WHAT WE'LL COVER:

In this section, we also discuss the following topics:

BRC stands for British Retail Consortium. BRC meaning refers to the leading trade association in the UK that developed the BRC Global Standards (BRCGS), which are widely applied within the food manufacturing, packaging, storage, and distribution industries.

The BRC is of the very first set of standards that the GFSI benchmarked.

Suppliers and food retailers use the standards globally to commitment to food safety and meet customer demands for high standards in food safety and quality management.

The BRC sets out standards for proper food processing and retail.

The BRC Global Standards are internationally recognised and set a benchmark for best practices in these sectors. They focus on areas such as food safety, quality, legality, and operational criteria.

These standards are widely recognised and utilised across the globe, especially in the food industry. The BRC has different sets of standards tailored for specific sectors.

BRCGS are widely used globally and have been adopted by over 22,000 locations in more than 130 countries.

Some of the BRC standards include the following:

These standards are periodically reviewed and updated to align with the latest industry best practices, regulatory requirements, and changes in global supply chain management dynamics to maintain their relevance and effectiveness.

Compliance with these standards often involves undergoing food audits and assessments to obtain certification.

Fulfil one of the most critical legal requirements of BRC by using FoodDocs' smart Food Safety Management System. With the help of our software, you can get a comprehensive monitoring system that can record key operations in your business with customisable monitoring tasks.

The primary purpose of the British Retail Consortium (BRC) and its BRC Global Standards is to establish and maintain standards that ensure safety, quality, and operational criteria within various industries, especially the food, packaging, and consumer goods sectors.

Compliance with BRC standards assures customers of your commitment to food safety and continuous operations improvement.

In particular, here are some key significance of the BRC:

Continuous Improvement. The BRC standards evolve to keep pace with changing regulations, technologies, and best practices. They encourage companies to continually improve their processes, improving food safety, product quality, and operational efficiency.

By establishing standardised benchmarks, enabling continuous improvement, and instilling confidence in supply chains, the BRCGS elevates production, storage, and distribution standards and strengthens consumer trust.

The key changes to the BRCGS version 9 lie in the new requirements that further ensure the applicability of the standards on a global level. The changes to the standards were first published in August 2022 and are set to take effect on February 1, 2023.

Here are some of the new and revised items in the 9th edition of the BRC food safety certification scheme:

These revisions are just some of the key changes. You can find more information on the BRCGS website.

The BRC Global Standard (BRCGS) certification is a widely recognised accreditation in the food supply chain.

The BRC Global Standards cover various sectors such as food safety, packaging, storage, distribution, and consumer products.

The BRCGS certification is obtained through assessments and audits conducted by accredited third-party certification bodies.

It signifies that a company complies with the established food standards and practices, demonstrating a commitment to maintaining high levels of safety and quality throughout the production, storage, and distribution processes.

Becoming BRC-certified refers to a company or facility that has successfully undergone an audit and assessment according to the standards set by the British Retail Consortium (BRC).

Achieving BRC certification indicates that the company or facility complies with strict food safety and quality criteria. It also shows that the business has complete operational control over a wide range of food processes.

BRCGS-certified logos are granted to companies that have successfully achieved certification according to the BRCGS standards, and they are authorised to use these logos on their products, packaging, websites, and marketing materials. It serves as a mark of food quality and having passed the fundamental requirements of the program.

The BRCGS logos visually represent a company's certification status and commitment to meeting the tough requirements set by the BRCGS. These logos vary based on the specific standard for which the company is certified (e.g., Food Safety, Packaging, Storage & Distribution), and they often include the BRCGS name or symbol alongside the certification level or standard achieved.

BRC Global Standards offer different certification levels based on the outcome of the audit and the compliance level with their standards. The levels generally represent the degree of compliance and achievement in meeting the requirements of the specific BRC standard.

The levels awarded by BRC include the following:

Lower grades, such as C and D, are given to companies that require major attention.

The certification levels can vary depending on the standard being applied, and the criteria might differ slightly between each specific BRC Global Standard.

The levels are based on the audit outcomes, the adherence to the requirements, and the management of the facility's processes following the standard's guidelines.

If the auditor finds critical non-conformance in your operations, you may be awarded a lower grade. Despite this, you will be given enough time to apply corrective actions for major non-conformance.

Essentially, any food business within the food industry that values and prioritizes high standards of food safety may seek BRCGS certification.

This demonstrates their commitment to these principles and to establishing trust with their customers, suppliers, and stakeholders.

Businesses that often seek BRCGS certification include the following:

Food Manufacturers. Companies involved in food production and processing, including those handling perishable goods, beverages, and other consumables, often seek BRCGS certification to demonstrate their commitment to food safety and quality.

Packaging Manufacturers. Businesses involved in producing packaging materials used in food and other industries opt for BRCGS certification to ensure the safety and quality of their products.

Storage and Distribution Centers. Warehouses, logistics, and distribution facilities handling food, consumer products, and even non-food items may seek certification to guarantee these goods' safe handling and storage.

Retailers and Suppliers. Retailers and suppliers often require their vendors and partners to have BRCGS certification as a condition for doing business. A supplier approval process ensures the safety and quality of the products they sell or distribute.

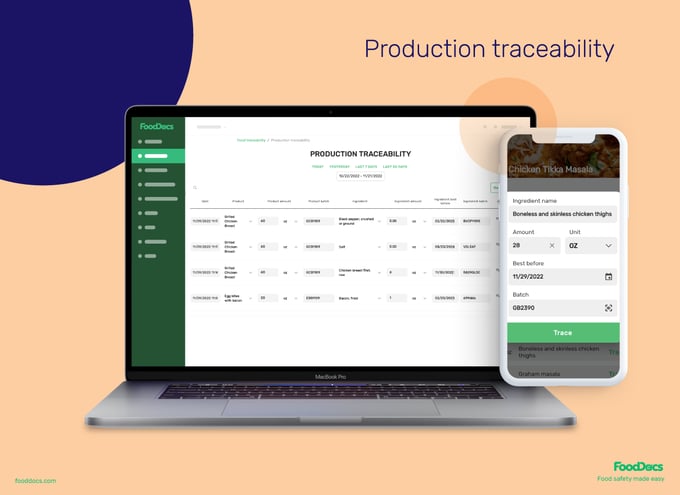

Food businesses can easily get BRCGS certification with the help of FoodDocs' smart Food Safety Management System. Using our software, you can establish a monitoring system complete with a Traceability System in one.

Log all information about your operations and ensure food safety compliance with the help of our intuitive software.

Obtaining a BRCGS certification involves several steps leading to a strong food safety system.

Working with a dedicated team, possibly involving quality assurance, operations, and management, is crucial to achieving and successfully maintaining BRCGS certification.

Here are 10 steps for you to get BRCGS-certified:

Understand the standard. Familiarise yourself with the specific BRCGS standard for your industry or business. Each standard has its requirements; understanding these is crucial before the certification process begins.

Prepare and assess. Evaluate your current processes, procedures, preventive actions, and systems against the BRCGS requirements. Identify product control areas that need improvement to meet the standard's criteria.

Train your team. Conduct food safety training for your staff and implement necessary changes to ensure legal compliance with the BRCGS standard. Document all processes and procedures to maintain consistency and traceability within the range of training courses.

Choose a certification body. Select an accredited certification body recognised by BRCGS to conduct your audit. This body will assess your facility and operations against the BRCGS standard.

Pre-audit assessment. Some companies conduct a pre-audit or mock audit to identify any potential deviation from requirements or areas for improvement before the official certification audit.

Schedule the BRCGS food safety audit. Coordinate with the chosen certification body to schedule the official certification audit. The auditors will review your systems, procedures, and facilities to ensure compliance with the BRCGS standard.

Facilitate the audit: During the audit, any non-conformities or areas for improvement will be identified. You will be provided with a report, and if there are any non-conformities, you'll need to address these through corrective actions.

Certification decision: Once corrective actions are completed, the certification body will review the evidence and determine whether to award BRCGS certification.

Maintain and renew certification: Once certified, it's essential to maintain compliance with the BRCGS standard. Periodic audits will be conducted to ensure ongoing adherence. Certifications typically need renewal after a set period.

Remember that the BRCGS food safety standard for a business in the packaging industry will always vary from those for the retail industry. Understanding the key legal obligations you must fulfil is key to securing a BRCGS certification.

Ensure that your team is well-prepared and your business has a high level of facility management for the certification evaluation by using FoodDocs' AI-powered Food Safety Management System.

Using our smart software, you get a comprehensive food safety system and can also perform internal audits. Use our smart auditing tools to assess your operational conformance with BRCGS food safety standards. Incorporate the key elements of the certification program into your audit checklists and find key areas that need improvement.

Implementing the BRCGS standards does more than ensure food safety. It also ensures that a business has the tools and systems to fight food fraud and boost its safety culture.

Having been considered one of the longest-running benchmarked standards by the GFSI, the BRCGS certification ensures that your business is holistically safe from food safety hazards and other key issues in the food industry.

Preparing and establishing a comprehensive system for your food business are keys to ensuring a successful certification process. Use FoodDocs' intuitive Food Safety Management System to fulfil BRCGS requirements with the help of the following features:

Ensure that your business is compliant with BRCGS standards by implementing FoodDocs' intuitive Food Safety System. With our software, you can get automatically generated monitoring tasks that can be used to monitor compliance with food safety tasks.

Get monitoring tasks for recording critical information about your operations, such as cooking temperature, storage conditions, and personal hygiene. Here are some examples of the tasks that you can get.

Customisable monitoring tasks from FoodDocs software

Moreover, you can also further improve each task according to your business needs, as all monitoring tasks are customisable. Incorporate unique information and parameters by editing the monitoring tasks or creating new forms from scratch.

Use the information you gather as proof of your compliance with BRCGS standards.

One of the essential elements in obtaining BRCGS certification is establishing a robust system to oversee raw material and finished product movement in the food chain.

Our innovative Food Safety Management System serves the dual purpose of monitoring and tracing safe products. Utilise our system to efficiently log and retrieve detailed information about product batches and their ingredients.

Our Traceability System ensures easy access to historical data during crucial periods such as food recalls or other legal issues, significantly enhancing production management. Furthermore, our system boasts advanced search features that swiftly locate specific product-related documentation, streamlining processes and ensuring efficiency.

Traceability system from FoodDocs software

Utilise FoodDocs' comprehensive system to prepare your team for the BRCGS certification journey. Easily upload existing audit checklists or create new ones from scratch, facilitating in-house assessments through any mobile device.

To ensure that your team and operations are ready, perform internal audits in preparation for the BRCGS scheduled audit. Quickly pinpoint key areas that need more information using our auditing tools.

Integrate insights garnered from gap analysis into your existing audit checklists, assessing the team's efficacy in resolving identified issues. These versatile tools empower proactive measures, ensuring a more streamlined path toward certification.

Food safety audits from FoodDocs software

BRCGS certification highlights a company's ongoing commitment to keeping its processes safe and top-quality. It means they continuously work to improve how they handle food, ensuring it's safe at every step.

The certification program shows a company's dedication to top-notch food safety, quality, and good operations. Prepare your team for an upcoming audit for the BRCGS certification and secure continuous improvement with the help of FoodDocs' intuitive Food Safety Management System.

Book a free demo to understand how our system can help you secure a BRCGS certificate and more.

BRC certification in the UK is a quality assurance recognition, ensuring that companies operating in various industries, notably food production, adhere to stringent safety and quality standards set by the British Retail Consortium (BRC).

The BRC standard is a set of guidelines developed by the British Retail Consortium, focusing on food safety and quality. It outlines best practices in manufacturing, packaging, storage, and distribution within the food industry.

The most recent BRC standard was the BRC Global Standard for Food Safety Issue 9, encompassing updated guidelines and criteria for ensuring food safety and quality.

The distinction between BRC and BRCGS is more a matter of terminology evolution. BRCGS (BRC Global Standards) refers to the same standards. Still, the change in naming reflects a shift to emphasise the global nature and broader applicability of these standards beyond the UK market.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...