Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

The Safe Quality Food (SQF) program is considered a gold standard for food safety and quality in the entire food supply chain.

The SQF is a GFSI-benchmarked certification program that ensures a globally-recognized level of food safety and quality standards.

The SQF program is based on the principles of the HACCP system and incorporates deeper food safety management programs.

You can satisfy all the requirements of the SQF certification program and build a HACCP-based food safety system using our digital solutions at FoodDocs.

The main efforts of the food industry to protect customers from foodborne illnesses are seen through the strict food safety standards that experts established. A well-known proof and example of this is the SQF program, otherwise known as the Safe Quality Food program.

The globally-known food safety certification model is a sign of a certified business' commitment to protecting and serving consumers. The program aims to show how food safety is very important in the industry. The SQF program requires an extensive compilation of documents regarding the policies adopted by a food business and how the team implements them within everyday operations. The program ensures that every gap and hazard in a food business is properly identified and analyzed to protect consumers from food safety problems and quality complaints. SQF-certified food businesses are expected to be more globally competitive and have a better reception from food providers all over the world.

Find out what does SQF mean and how to establish a HACCP-based food safety management system, which is the main requirement of an SQF program, with the help of FoodDocs.

Here is a list of the topics discussed in this piece:

WHAT WE'LL COVER:

SQF means Safe Quality Foods. The SQF program started as a food safety standard that was developed in Australia in 1994. Currently, the program is considered an internationally recognized certification system for food safety and quality management.

The SQF food safety program is managed by the Safe Quality Food Institute (SQFI), a subunit of the Food Marketing Institute. To date, the SQF certification program is considered a Global Food Safety Initiative (GFSI) benchmark for auditing food businesses worldwide. The GFSI is a privately owned organization that manages auditing bodies and sets criteria for food safety management systems all over the world.

In the food industry, the SQF meaning is synonymous with a very high food safety system.

Food business owners would benefit significantly by understanding what is SQF and how can it improve food safety. The SQF program applies to all sectors of the food supply chain, whether food manufacturing, service, or retail of food products.

Companies audited by an SQF-certified body can assure their customers that the business is operating under a well-structured and strict food safety management system. The goal of a GFSI-recognized program, such as the SQF, is to ensure that food businesses are well-equipped with the required food safety measures.

The SQF program covers food safety and quality controls for all areas of the food supply chain. The program requires controls from farming up to the distribution of food products to the customers.

The program can specifically offer food companies the following benefits when established:

An SQF certification opens doors for any certified food business. It serves as a written confirmation that your team follows the highest food safety standards known in the industry.

Did you know that food safety statistics of food facilities that implemented a GFSI-recognized program saw 34% fewer cases of recalls?

The SQF offers modular programs on basic food safety as well as additional modules that cover specific food safety programs, such as the Food Safety Modernization Act of the U.S.

The SQF certification program is a voluntary auditing system. Although voluntary, it covers the majority of the regulatory requirements established by federal government agencies, such as the U.S. Food and Drug Administration and Canada's Canadian Food Inspection Agency.

The Safe Quality Foods standards are applicable to all food businesses starting from the farm level up to the distribution channels of food products, such as retail stores.

The SQF program offers modules for the different sectors of a food production system. Some of the areas covered by the most recent version of the SQF program include the following:

Food businesses dealing with any of the mentioned sectors can take the certification program.

The Safe Quality Foods standards can be summarized into three basic principles. Certification under the SQF standards reflects the commitment of a company to food safety based on the following principles:

The SQF standards are established to ensure that a food company correctly and efficiently manages food safety risks through a comprehensive food safety management system.

The SQF standard programs are subdivided into three different levels for food business teams. Each level addresses different food industry requirements with increasing degrees of criticality.

Establishing a HACCP food safety plan covers the majority of the SQF standard requirements. Having a comprehensive HACCP plan can help ensure your compliance with an SQF certification program easily.

Using FoodDocs' digital solutions, you can get both a digital HACCP plan and a HACCP-based food safety management system in one. Our system can automatically generate a comprehensive digital HACCP plan with automatically defined CCPs that you can further customize and a food safety management system based on this safety plan. You can satisfy all of the requirements and ace the audit process with our solutions.

Use our free 14-day trial to experience how we can make your certification compliance easier!

The SQF Code Edition 9 is the latest version of the SQF standards. Major changes in manufacturing categorization and auditing point system were established for the SQF code edition 9. More specific fields of manufacturing were explained in detail and guidelines were set for each field.

Effective last May 2021, all certification audits under the SQF program will be performed according to the 9th edition. The changes created under the SQF Edition 9 made the program applicable to other GFSI-recognized standards.

The previous editions of the SQF Code highlighted manufacturing fields in groups. The SQF Code Edition 8.1 covered plants, livestock, and aquaculture in one module, whereas the 9th edition laid out separate guidelines for each field.

To highlight the most significant SQF Code changes from the 7.2 and 8.1 editions, check out this list:

Businesses transitioning from Code Edition 8.1 to the 9th Edition can start by performing a gap analysis and a further assessment of their food safety programs.

The SQFI provides clear guidance documents for transitioning and implementing the food safety and quality codes of the new SQF Code Edition.

The SQF audit serves as the verification part of the program after establishing a food safety management system following their guide. The audit ensures that your food business is compliant with the most current edition of the SQF Code and that your team is following the applicable food laws.

To date, SQF audits are conducted in two parts, which consist of a remote document audit and an on-site audit. The entire SQF audit process works like a regular food safety audit.

A certified auditing body representative will send an audit plan to your team for a scheduled visit. During the audit, the inspector will systematically analyze your documentation and on-site operations based on the SQF Code. After the process, a report will be provided to your team for review. All suggested corrective actions must be applied within the deadline specified by the auditor.

Your team will earn a certification once the audit is passed and the food business is now "SQF-certified."

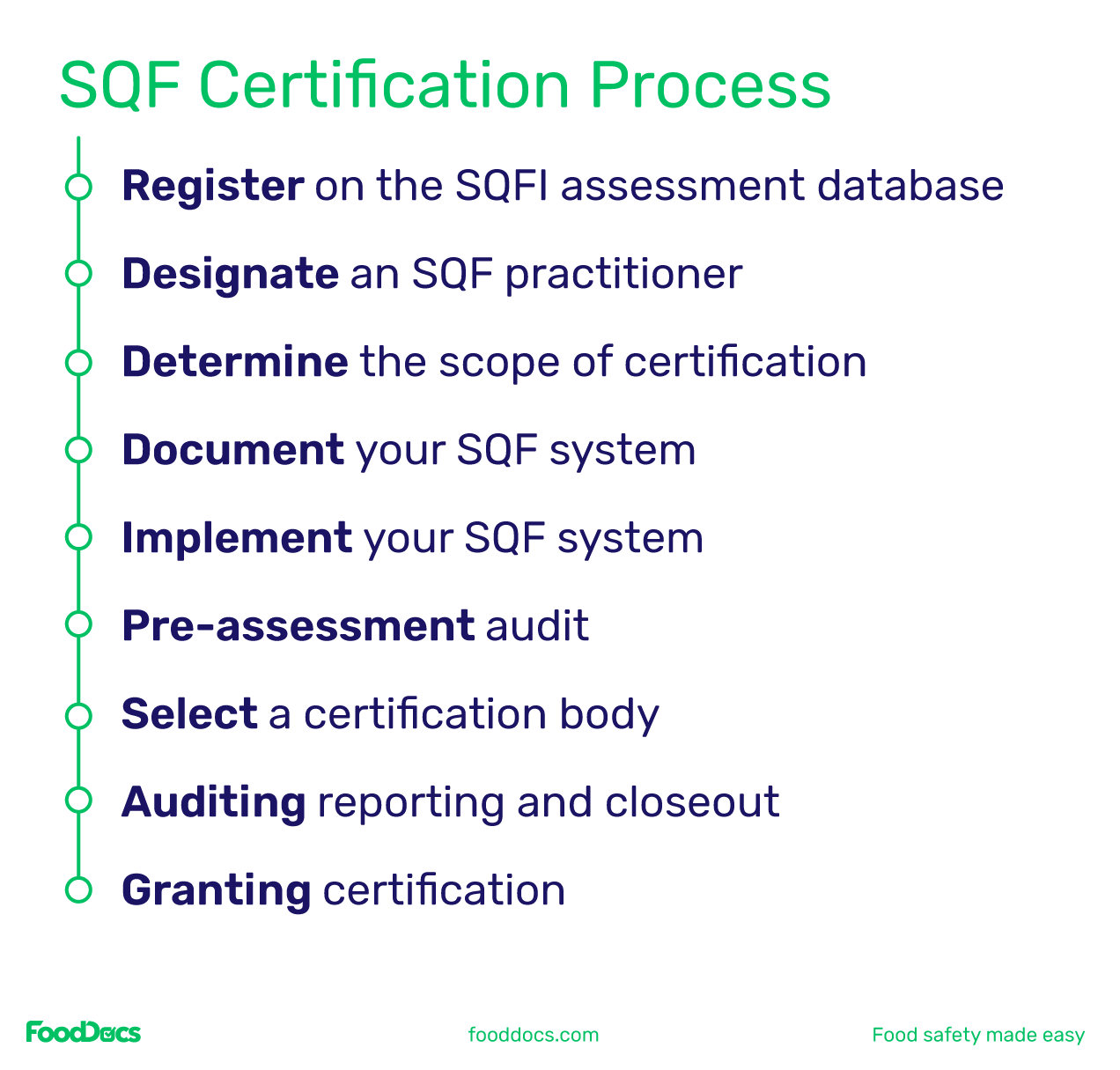

SQF Certification Process

The SQF certification program significantly varies depending on the process being audited. Guidelines for sites for inspection and document control requirements are provided by the SQFI.

The certification process involves ten detailed steps as described by the SQFI:

Determine the most appropriate classification of program and certification costs fit for your business.

The selected SQF practitioner will represent the site management and ensure the effectiveness of the food safety system. A designated practitioner must meet the following requirements:

Choose the level of certification appropriate for your food operations and target certification.

Review the latest SQF Code and document the necessary and applicable guidelines in your operations. Document all systems, work operations, and policies of your processes.

Implement all documented policies into your everyday operations.

Perform an in-house assessment with an assigned SQF practitioner to identify any potential gaps in your program.

Choose an SQFI-accredited certification body that offers a program suitable for your facility's needs.

The certification body will perform document and on-site reviews on the scheduled date and time.

All non-compliance and major points for improvement are collected and reported to the team for correcting.

If the auditor evaluated your food business as compliant with the necessary requirements and all corrective actions are applied, your food business will be declared Safe Quality Foods certified.

The SQFI also provides training to prepare food business teams for the actual audit. The auditing process usually takes 3 to 4 days to conclude, with an additional allotted time for preparation. The process will take more time depending on the number of corrective actions suggested.

The certification process can easily conclude if your food business already has a HACCP plan in place. Implementing the HACCP features covers the majority of the SQF Code.

Establish your own HACCP plan in just 1 hour with the help of our digital HACCP plan builder and get SQF-certified fast. By simply answering a few questions about your operations, our system can automatically generate a comprehensive HACCP plan template that you can further customize to fit your business.

The tasks involved in an SQF audit depend on the program you are getting certified for. To help you cover the basic parts of the SQF audits program, use this SQF audit checklist we prepared:

More detailed and specific checklists based on the certification program you are aiming for are provided by the SQFI. You can also check out our free internal SQF audit checklist!

SQF training refers to the programs offered by the SQFI or certified companies that help prepare businesses for the certification process. The SQFI itself provides training programs for SQF practitioners and in-person training for business teams.

An SQF practitioner training program includes modules for courses that discuss the implementation scheme of the SQF. The training program discusses the fundamentals of SQF and how it can help food businesses. It also includes the major changes in the SQF Code Edition 9.

The Safe Quality Foods program is based on the HACCP principles. Establishing a comprehensive HACCP plan is an essential first step to passing an SQF certification audit. SQF certification is a strict program that will need a lot of your time as a food business owner.

Once your team has established a HACCP plan, the SQF program will still require you to document the entire food safety management system. At FoodDocs, you can get both objectives done in record time. With our digital solution, you can get a customizable HACCP-based food safety management system that satisfies the SQF program.

Using our built-in customizable HACCP plan builder, you can get a comprehensive HACCP plan template in just 1 hour. All you need to do is describe your operations to our system, and it will automatically generate a detailed template for you.

Our digital HACCP plan builder will provide the following sections of your food safety plan:

.png?width=1065&height=924&name=HACCP_template%20(1).png)

HACCP plan Template from FoodDocs

Using artificial intelligence and a machine-learning program, our system can quickly create all the essential documents needed for a HACCP program. You can even further customize the HACCP plan according to the additional requirements of the SQF Code.

Store all your HACCP-related documents and easily share them with the SQF practitioner with the dedicated cloud file storage for your team.

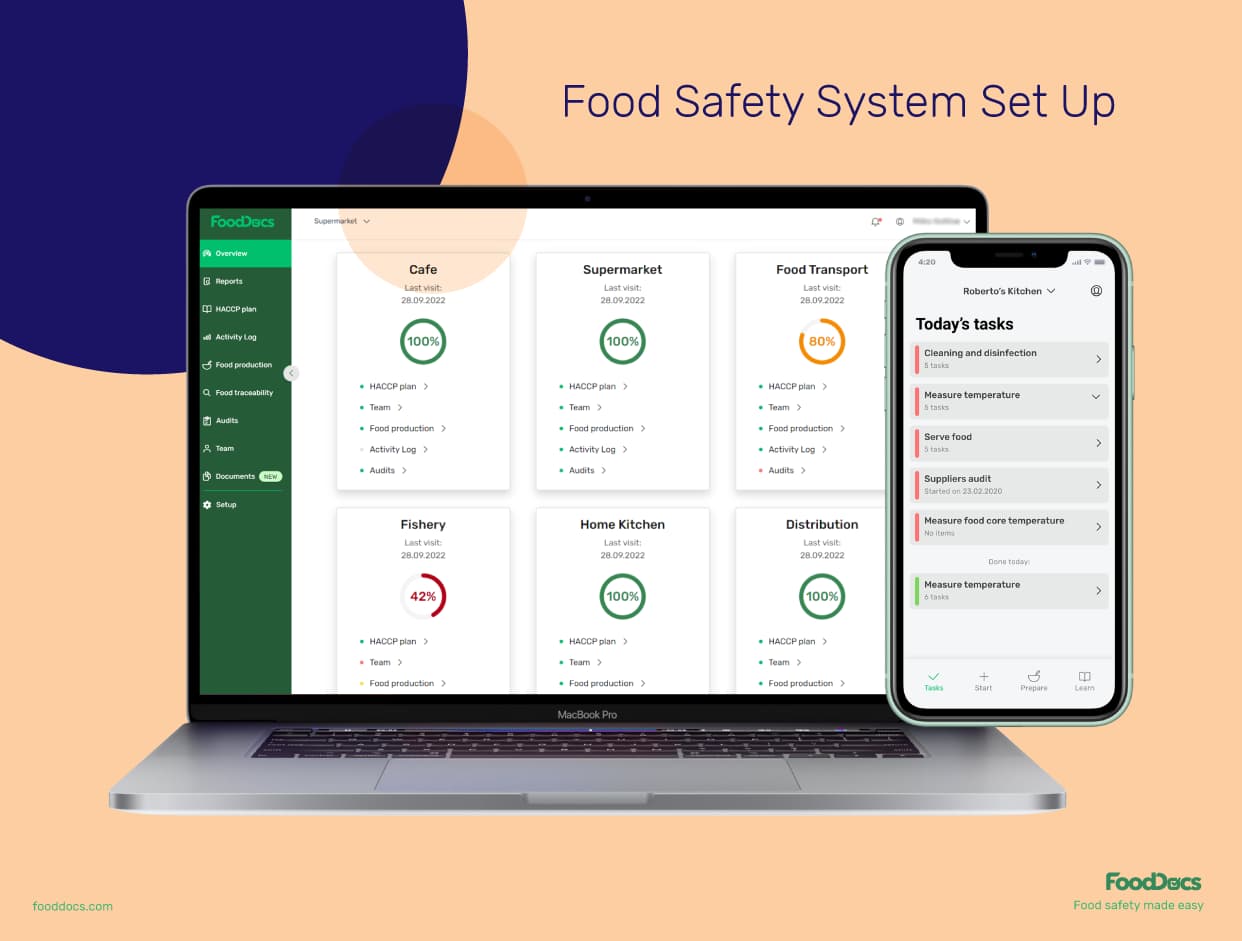

FoodDocs' software is mainly a HACCP-based food safety management system, which is what the SQF program requires. With our digital Food Safety Management System, you can intuitively and efficiently document all policies and food safety tasks. Setting up our digital FSMS software takes only 15 minutes.

With our system, you can check all boxes from the SQF Code requirements. Get the following features that will help you pass an SQF certification and consistently maintain compliance:

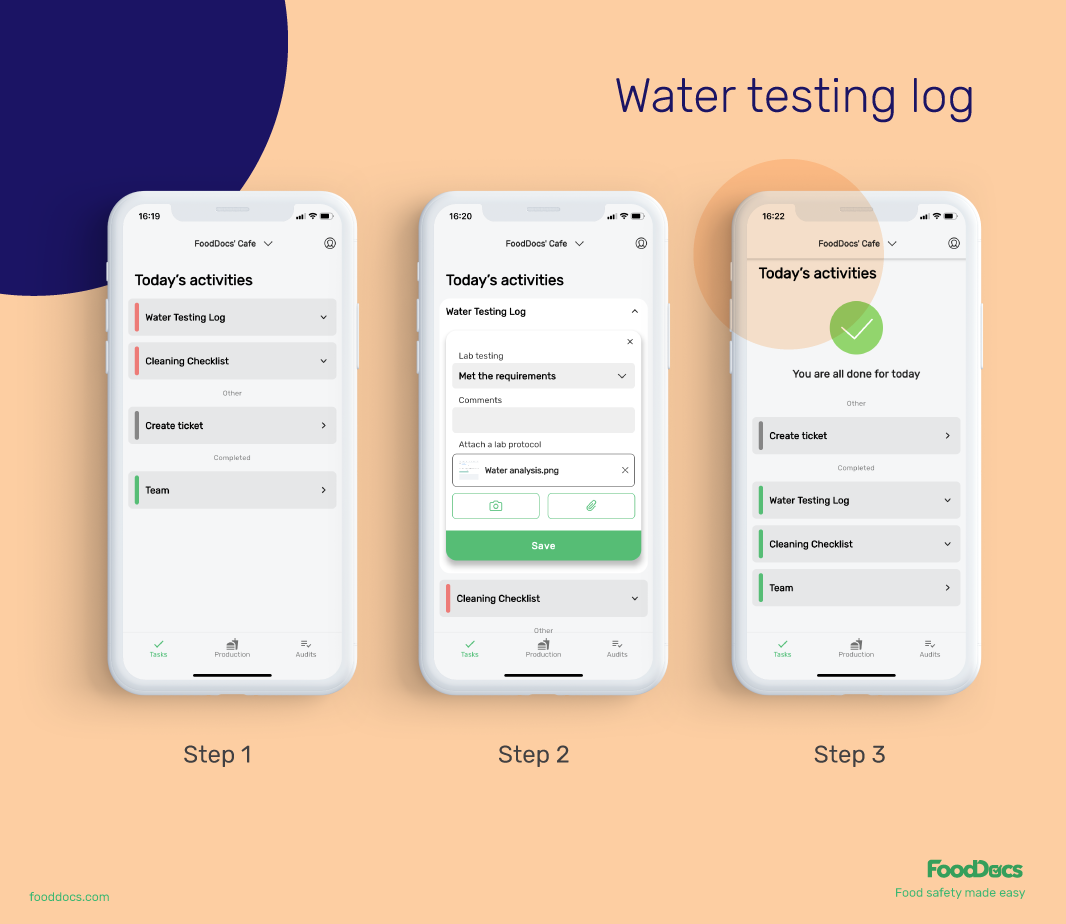

Water Testing Log from FoodDocs

Food Safety System Set Up from FoodDocs

The SQF program used to rely significantly on paper-based documentation. As the industry moved towards the digital era, achieving an SQF certification has become more convenient. With our digital platform, the SQF certification can be a breeze.

Get SQF-certified with the help of our digital solutions. Our system accommodates easy customizations so you can incorporate additional SQF requirements. You can also use this feature to incorporate suggestions from the SQF auditor or create new digital monitoring logs based on the new SQF Code edition.

Start using our system and prepare your team with an internal audit using our software programs now. Use our free 14-day trial to ace your pre-assessment audit and continue your compliance status by purchasing our services now.

Do you need more information about the SQF program? Here are some frequently asked questions about the GFSI-certified certification system.

SQF stands for Safe Quality Foods.

The SQF is a certification system that contains sets of food safety standards based on the HACCP program. The program aims to ensure that certified food businesses are only producing safe and quality foods and are compliant with applicable food laws.

The three main requirements of an SQF certification program are summarized through the following standards:

The SQF certification is globally known and highly favored by food businesses, including service providers, retailers, and food manufacturers, who require a comprehensive food safety management system.

The term SQF certified is awarded to food businesses that satisfied the requirements and standards established in the SQF Code. This title can be achieved by undergoing the SQF certification audit.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...