ECOSURE INSPECTION CHECKLIST | FREE DOWNLOAD

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

In a Food Safety Insights survey about businesses' top priorities for their food safety programs going into 2025, three topics took the majority of total responses:

- Food safety culture (20%)

- Microbiolotical/Environmental monitoring (20%)

- Sanitation/Hygiene standards (16%)

As a Food Safety or Quality Manager, those same priorities ring true because you understand the importance of maintaining a clean and safe environment for your customers. One way to ensure this is by conducting regular EcoSure inspections, which evaluate the safety and quality of your food handling and preparation processes. That's what this free EcoSure inspection checklist is designed to help you do.

Key takeaways

-

Food safety culture and microbiological and environmental monitoring are top priorities for food businesses in 2025, with "food safety culture" and "sanitation standards" leading industry concerns.

-

Regular EcoSure inspections are essential for evaluating and improving food handling, preparation, and safety compliance.

-

The EcoSure inspection checklist includes key safety areas such as hygiene, sanitation, pest control, and documentation.

-

Proper food storage and handling practices, including temperature control and separation of raw and cooked foods, are emphasized in inspections.

-

Employee hygiene is a major inspection focus, ensuring handwashing, glove use, and hair restraint policies are followed.

-

Inspections assess for pest activity and verify that pest prevention systems are in place and maintained.

-

Regular maintenance ensures that kitchen equipment is functioning correctly and doesn't pose food safety risks.

-

Establishments must have clear emergency procedures for situations like foodborne illness outbreaks or power failures.

-

Inspectors review documentation to ensure cleaning logs, training records, and temperature checks are accurate and up-to-date.

-

Best practices like self-inspections, food safety training, and digital record-keeping improve inspection outcomes and ongoing compliance.

If your business uses EcoSure's food safety program (which is likely why you're reading this), you'll understand why inspections are critical for any food safety program.

But if you're learning more about EcoSure's food safety program and what an inspection or audit process looks like, then keep reading to learn more about the solution they offer as well as how you can reduce the risk of foodborne illnesses, improve customer trust and confidence, and enhance your reputation and brand protection.

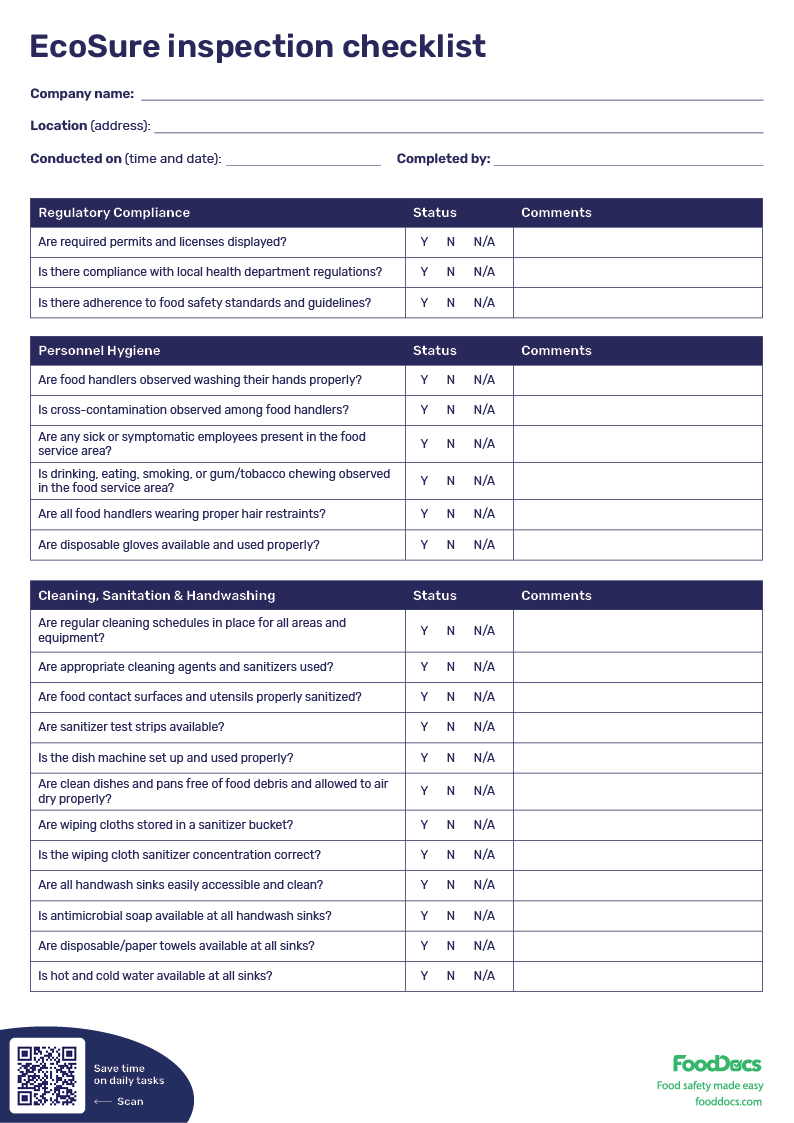

What's on this EcoSure inspection checklist PDF?

In addition to details such as your company name, location, date and time the inspection is conducted, and who completed it, this EcoSure inspection checklist covers the following food safety areas:

|

REGULATORY COMPLIANCE |

|

Are required permits and licenses displayed? |

|

Is there compliance with local health department regulations? |

|

Is there adherence to food safety standards and guidelines? |

|

PERSONNEL HYGIENE |

|

Are food handlers observed washing their hands properly? |

|

Is cross-contamination observed among food handlers? |

|

Are any sick or symptomatic employees present in the food service area? |

|

Is drinking, eating, smoking, or gum/tobacco chewing observed in the food service area? |

|

Are all food handlers wearing proper hair restraints? |

|

Are disposable gloves available and used properly? |

|

CLEANING, SANITATION & HANDWASHING |

|

Are regular cleaning schedules in place for all areas and equipment? |

|

Are appropriate cleaning agents and sanitizers used? |

|

Are food contact surfaces and utensils properly sanitized? |

|

Are sanitizer test strips available? |

|

Is the dish machine set up and used properly? |

|

Are clean dishes and pans free of food debris and allowed to air dry properly? |

|

Are wiping cloths stored in a sanitizer bucket? |

|

Is the wiping cloth sanitizer concentration correct? |

|

Are all handwash sinks easily accessible and clean? |

|

Is antimicrobial soap available at all handwash sinks? |

|

Are disposable/paper towels available at all sinks? |

|

Is hot and cold water available at all sinks? |

|

PEST CONTROL |

|

Are there any signs of pests or rodents in the establishment? |

|

Are proper pest control measures in place? |

|

Are entry points sealed to prevent pest intrusion? |

|

Are pest control devices in place and regularly maintained? |

|

Are food and waste stored in pest-proof containers? |

|

ALLERGEN MANAGEMENT |

|

Are allergens clearly labeled on menus and food items? |

|

Have food handlers received proper training on handling and preventing cross-contact with allergens? |

|

Are allergenic ingredients separated to avoid cross-contamination? |

|

WASTE MANAGEMENT |

|

Is waste and trash disposed of properly in sealed containers? |

|

Is waste regularly removed to prevent odors and pest attraction? |

|

Are different types of waste separated where applicable? |

|

EQUIPMENT MAINTENANCE |

|

Are kitchen equipment and appliances regularly inspected and maintained? |

|

Are temperature gauges and appliances calibrated? |

|

Is damaged equipment immediately repaired or replaced? |

|

EMERGENCY PROCEDURES |

|

Are procedures in place for handling foodborne illness outbreaks? |

|

Is emergency contact information available? |

|

Have employees been trained on emergency procedures? |

|

Are fire extinguishers and other safety equipment easily accessible and inspected regularly? |

|

FOOD STORAGE & HANDLING |

|

Are perishable items stored at proper temperatures? |

|

Are raw and cooked foods separated to prevent cross-contamination? |

|

Are stored food items properly labeled and dated? |

|

Are any expired products present? |

|

Are there any swollen, dented, or rusted cans in storage, or other damaged packaging? |

|

FOOD PREPARATION & COOKING |

|

Are calibrated thermometers used to check cooking temperatures? |

|

Are proper thawing methods used for frozen foods? |

|

Are utensils and surfaces sanitized between food preparations? |

|

Is packaged food stored in contact with water or ice? |

|

Are pre-chilled ingredients used in salads and sandwiches? |

|

Are pasteurized eggs used for uncooked products? |

|

Are raw, whole shell eggs pooled? |

|

Are proper thawing techniques used? |

|

Is hazardous food left at room temperature? |

|

DOCUMENTATION & TRAINING |

|

Are records of cleaning schedules, maintenance, and staff training available? |

|

Is evidence of ongoing staff training on food safety protocols available? |

|

Are logs for temperature checks and other critical control points maintained? |

|

CUSTOMER SAFETY |

|

Are walkways and exits free of obstructions? |

|

Is proper signage in place for wet floors and other hazards? |

|

Are emergency exits clearly marked and accessible? |

|

Are first aid kits available and stocked? |

What does EcoSure partner with food businesses to do?

There are six key areas that EcoSure partners with food businesses to accomplish:

- Determine program priority areas: EcoSure collaborates with your leadership team to identify the most critical areas for your brand, such as food safety, public health, guest experience, sustainability, and workplace safety. For instance, a quick-service restaurant might prioritize food safety and speed of service, while a food production facility may focus on sanitation and contamination prevention.

- Customize program design: Based on your identified priorities, EcoSure designs a tailored program that aligns with your operational goals and brand standards. This includes developing specific assessment criteria, reporting structures, and food safety training modules that address your unique challenges and objectives.

- Conduct on-site visits: EcoSure's expert team performs regular on-site assessments to evaluate compliance with established protocols and identify areas for improvement. These visits provide real-time insights into everyday operations, allowing for immediate feedback and corrective actions.

- Discover actionable insights: Using data collected from assessments, EcoSure provides detailed reports and dashboards that highlight trends, pinpoint problem areas, and offer actionable recommendations. This data-driven approach enables you to make informed decisions to enhance operational efficiency and safety.

- Recommend program enhancements: EcoSure continuously monitors the effectiveness of your program and suggests enhancements to address emerging challenges or changes in regulations. This proactive approach ensures your operations remain compliant and aligned with industry best practices.

- Deliver an elevated customer experience across your brand: By integrating assessments of customer-facing elements, such as service quality and facility cleanliness, EcoSure helps you maintain a consistent and high-quality customer experience. This consistency strengthens brand reputation and fosters customer loyalty.

What's the goal of EcoSure's food safety program?

EcoSure's primary goal is to help create a custom food safety program for your business. Whether you're in a food and beverage processing plant or work in the food service and restaurant industry, in their own words:

EcoSure’s program empowers your teams to proactively address food safety concerns and related operational issues, minimize risk and create spaces that will drive customer satisfaction and improve brand reputation.

To accomplish that goal, you can expect their team to explore:

- Cooking temperatures: Proper cooking temperatures are crucial in preparing your dishes to perfection and decreasing the chance of transmitting harmful pathogens.

- Food safety knowledge: They assess the food safety knowledge of your team, empowering them to maintain impeccable standards throughout your operation.

- Contamination prevention: Safety begins at the source. They help you implement contamination prevention measures, with the goal of safeguarding your products from start to finish.

- Beverage stations: They evaluate your bar and beverage stations for proper maintenance and cleanliness practices.

- Hot and/or cold holding: Temperature control is critical. They verify that your hot holding and cold holding equipment maintains the ideal conditions to keep food safe.

- Food preparation and storage: Their experts inspect every step in your food-handling processes to ensure compliance with safety standards.

What is an EcoSure Inspection?

An EcoSure inspection is a comprehensive evaluation of your food handling and preparation processes, including your facilities, equipment, and personnel. The inspection is designed to assess your compliance with food safety regulations and standards, as well as your overall food safety culture.

The EcoSure inspection checklist is a valuable tool that can help you prepare for and conduct an EcoSure inspection. The checklist includes a range of categories and sections, such as personnel hygiene, cleaning and sanitation, pest control, and food storage and handling.

Why are EcoSure audits important for food service and production businesses?

EcoSure audits are essential for food businesses as they help ensure that your food handling and preparation processes are safe and compliant with the requirements of regulatory bodies. By conducting regular EcoSure audits, you can:

- Reduce the risk of foodborne illnesses

- Improve customer trust and confidence

- Enhance your reputation and brand protection

- Ensure compliance with food safety regulations and standards

Conducting regular EcoSure audits will help prevent foodborne diseases and ensure that your food products are safe for consumption.

What does EcoSure check?

The EcoSure inspection checklist includes a range of categories and sections, such as:

- Facility cleanliness and sanitation: Inspectors assess the cleanliness of floors, walls, ceilings, and all food contact surfaces. They verify that cleaning protocols are effectively implemented, equipment and utensils are properly sanitized, and pest control measures are active and effective.

- Food storage and handling: Evaluations ensure that perishable items are stored at safe temperatures (cold foods below 41°F, hot foods above 135°F), properly labeled with expiration dates, and that raw and cooked foods are stored separately for cross-contamination prevention.

- Employee hygiene: The inspection verifies that employees practice proper handwashing techniques, wear clean uniforms and appropriate hair restraints, and use disposable gloves correctly when handling ready-to-eat foods. It also checks for compliance with policies prohibiting eating, drinking, or smoking in food preparation areas.

- Food preparation: Inspectors confirm that cooking equipment is clean and well-maintained, proper internal cooking temperatures are achieved for all foods, and separate cutting boards and utensils are used for raw and cooked items to prevent cross-contamination.

- Chemical storage and use: The assessment ensures that chemicals are stored away from food and food contact surfaces, safety data sheets (SDS) are available for all chemicals, and employees are trained in the safe use and proper labeling of cleaning agents.

- Documentation and record keeping: Inspectors review records to confirm that temperature logs, cleaning schedules, pest control logs, and staff training documentation are up-to-date and accurately maintained, demonstrating ongoing compliance with food safety protocols.

- Equipment maintenance: The inspection includes checking that all equipment is functioning correctly, regularly maintained, and that any damaged equipment is promptly repaired or replaced to prevent potential food safety hazards.

- Emergency procedures: EcoSure evaluates whether the establishment has clear, documented emergency procedures in place for situations such as power outages, equipment failures, or foodborne illness outbreaks, ensuring that staff are trained to respond effectively.

The inspection will evaluate your compliance with food safety regulations and standards, as well as your overall food safety culture. The inspector will review your facilities, equipment, and personnel to identify potential risks and hazards that could compromise the safety and quality of your food products.

What are the best practices and strategies for EcoSure inspections?

To ensure a successful EcoSure inspection, it's essential to implement best practices and strategies that prioritize food safety and quality. Some tips include:

- Conducting regular self-inspections (aka mock inspections or internal audits) to identify potential risks and hazards.

- Implementing a food safety management system that includes procedures for handling and preparing food.

- Providing regular training and education for food handlers on food safety and quality procedures.

- Maintaining accurate and detailed records of food safety and quality procedures.

- Using digital checklists and inspection tools to streamline the monitoring of food safety practices and ensure real-time compliance tracking.

How to prepare for an EcoSure inspection?

To prepare for an EcoSure inspection, in addition to the best practices listed above, follow these tips to prepare for an EcoSure inspection:

- Reviewing and updating your food safety policies and procedures at a regular cadence (e.g., quarterly) or as things change

- Conducting regular self-inspections and audits to identify potential risks and hazards

- Providing regular training and education for food handlers on food safety and quality procedures

- Maintaining accurate and detailed records of food safety and quality procedures

How to understand EcoSure inspection scores and results

The EcoSure inspection report will provide a detailed evaluation of your food safety and quality procedures, including a score and recommendations for improvement.

The score will be based on your compliance with food safety regulations and standards, as well as your overall food safety culture. The report will also provide recommendations for improvement, which should be implemented to ensure that your food handling and preparation processes are safe and compliant with regulatory requirements.

How much does an EcoSure inspection cost? How long does it take?

On average, an EcoSure inspection can cost anywhere from $500 to $2,000, depending on the size and complexity of your food business. The inspection can take anywhere from a few hours to several days, depending on the scope and frequency of the inspection.

Some sources show a one-time assessment and training price of $325. However, this pricing seems to be company-specific pricing based on an assumed 1.5-hour time-on-site visit.

Factors affecting the cost and duration of EcoSure inspections include the size of the facility, the complexity of operations, the number of locations, and the specific services required during the inspection.

Is Ecolab the same as EcoSure?

Ecolab is a leading provider of food safety solutions and services, including the EcoSure program. The EcoSure program is designed to help food businesses ensure that their food handling and preparation processes are safe and compliant with regulatory requirements.

Ecolab provides a range of services and solutions to support food safety and quality, including training and education, consulting and assessment, and auditing and certification.

If you choose to partner with Ecolab, you can access a range of resources and expertise to help you maintain a safe and compliant food safety program.

How to use food safety management software to digitize your EcoSure monitoring program

EcoSure inspections are a critical component of any food safety program, as they help ensure that your food handling and preparation processes are safe and compliant with regulatory requirements.

As a business with a food safety program, you've still got to manage it. Compared to digital solutions, managing food safety on paper takes a lot longer and increases the risk of incomplete, damaged, or lost records.

You can use FoodDocs' digital Food Safety Management System and our easy-to-use mobile app in many ways to support your EcoSure program, including:

- Monitoring checks: Set up your Food Safety Management System in a matter of minutes by answering some simple questions about your business. Our AI creates your first monitoring tasks automatically, and you can start monitoring right after finishing your sign-up.

- Traceability logs: Choose the product you need to trace by searching manually or using the scanner (i.e., your phone or tablet camera) to speed up the process. Calculate product ingredients automatically by entering the amount that you need to produce and skip filling a separate production calculation log. Ingredient batch codes and best-before dates are pre-filled automatically based on previously used data to save you from filling in repetitive data.

- Internal audits: Promote accountability among your team by conducting regular food safety audits. Audits help you ensure that your business’s food safety standards are high.

Other features include fully customizable food safety tasks, automatic corrective action prompts, secure document storage, and more.

Try FoodDocs with a 14-day free trial or book a demo to get a personalized look at how food safety software can benefit your business.