Plus, download a free hot holding temperature log sheet!

Ensuring food is kept at safe temperatures isn’t just a legal requirement. It’s a critical food safety practice that prevents foodborne illnesses and keeps your customers happy.

While cold holding focuses on slowing down bacterial growth, hot holding keeps food out of the temperature danger zone, where amounts of bacteria can multiply.

This guide will walk you through everything you need to know about hot holding temperatures, from minimum requirements to essential safety tips.

What's the holding temp for hot food?

The general rule is simple: the holding temperature for hot food is 140°F or higher, according to the USDA. This is the baseline temperature that is in line with temperature danger zone food safety guidelines and ensures food stays safe from harmful bacteria such as E. coli.

Minimum hot holding temperature

Other state-specific resources from Minnesota Department of Health Food Business Safety and Florida Department of Agriculture and Consumer Services, for example, state that the minimum hot holding temperature for food is 135°F or higher.

Maximum hot holding temperature

But how high is too high? Technically, there’s no maximum hot holding temperature set by food safety regulations. But holding food at excessively high temperatures can cause problems.

Not only do you risk burning the food handlers working with the dishes and warming trays. The food quality will start to suffer, too. Nobody wants dried-out chicken or overcooked pasta.

So to be safe, food service operators should stick to that 140°F to ensure they're balancing both food safety and quality.

What is the correct temperature and time used for reheating hot holding food?

Reheating food for hot holding isn’t the same as simply reheating for immediate service. For one, the correct temperature and time for reheating hot holding food depends on where it was made.

Take this table, for example:

| If food is... |

It must reach... |

| Made in-house and reheated for hot holding |

Internal temperature of at least 165°F |

| Made in a food processing plant, opened in the food establishment, and reheated for hot holding |

Temperature of 135°F |

Always reheat food quickly — ideally within two hours — and make sure it reaches the safe internal temperature before serving or holding. When done right, reheating also helps retain both the safety and quality of the food.

But remember: internal cooking temperature comes first; meeting holding temperature comes second.

Before you can even think about holding food hot, it needs properly complete its cooking process. For example, one of the most common questions that pops up is:

What temperature should vegetables be cooked at to hold them hot?

The minimum internal temperature that vegetables should be cooked at to hold them hot is 135°F (57°C). This applies to both fresh vegetables as well as those that are commercially processed and in the ready-to-eat foods category.

This ensures that any harmful bacteria are eliminated before hot holding begins and reduces the risk of food poisoning. Once food hits that safe temperature, then you can move on to keeping it hot for service.

5 Safety tips for holding hot food

Maintaining safe hot holding temperatures isn’t just about keeping food at the right number. It’s about doing it in a way that keeps your kitchen efficient and your food safe. Here are some tips to ensure you're doing it right:

- Reheat food quickly: If you need to reheat food for hot holding, make sure it happens rapidly. Ideally within two hours. The faster it reaches the correct internal temperature, the safer it is.

- Preheat hot holding equipment: Never place food in cold or lukewarm equipment. Always preheat chafing dishes, soup kettles, and any other holding devices. Equipment that's not hot enough can promote dangerous growth of bacteria.

- Use the right equipment: Not all equipment is built for long-term hot holding. Invest in gear like chafing dishes or specialized food warmers that are designed to hold food safely for extended periods.

- Allow proper stand time: Follow the manufacturer’s instructions for food stand times. If none are available, allow at least two minutes of stand time for thorough heating.

- Cook food to a safe cooking temperature before holding: Hot holding equipment isn’t made to cook or reheat food. It’s designed to maintain safe temperatures. Always ensure food is fully cooked and steaming hot before putting it into the hot holding.

What to do if a food dish is not hot enough during hot holding

Despite your best efforts, sometimes food in hot holding just doesn’t stay hot enough. If you notice a dish dipping below the safe temperature, here’s what you can do:

- Reheat it once: Get the dish back up to steaming hot, then place it back into the hot holding equipment to prevent any food safety issues.

- Cool and reheat later: If reheating isn’t an option immediately, cool the food safely (e.g., two-stage cooling method) and reheat it again later to the proper temperature.

- Discard the food: If you can’t safely reheat or cool the food, it’s time to throw it away. While this isn’t ideal, serving food that’s been held below the safe temperature could lead to a foodborne illness outbreak.

How to prevent hot holding equipment from failing in the future

Maintaining the right temperature depends on more than just keeping an eye on the food thermometer. It’s also about making sure your food warming equipment is up to the task.

Here’s how you can prevent hot holding equipment from failing and resulting in food spoilage:

- Conduct regular audits: Schedule monthly inspections of your hot holding equipment to ensure everything is functioning correctly.

- Set a higher temperature baseline: Some kitchens play it safe by setting their hot holding equipment a few degrees above the required temperature. This buffer helps ensure food never falls into the danger zone temperature range.

- Train your food handlers: Food safety training should cover more than just cooking techniques, including the proper use and maintenance of hot holding equipment. Refresher courses on the most common food safety practices ensure that your team knows what to do if something goes wrong.

- Use kitchen thermometers regularly: Don’t rely solely on the equipment. Take occasional one-off temperature checks with a digital thermometer to make sure everything’s on track in the food warmers.

- Verify temperature logs: When dealing with any number of batches of food, it's critical that food handlers accurately record temps on a temperature log sheet, and supervisors verify that they've been recorded accurately to prevent any food safety issues.

With food safety management software like FoodDocs, you can enable verification tasks that make it easy to ensure your team is staying compliant and properly logging food temperatures that are outside of the temperature danger zone.

Hot holding temperature log (free download)

Speaking of that last point, we've created a free hot holding temperature log that food safety teams can use to record food safety temperatures.

Thank you for downloading our free template!

Want to create a full HACCP plan in 1 hour?

How about a digital Food Safety Management System in 15 minutes?

GET STARTED FREE

Popular hot holding temperature charts

We've also got a chart with general hot holding temperature guidelines as well as more specific food products:

Food service operators should have a clear, easy-to-reference hot holding temperature chart that's readily available in any commercial kitchen. It helps ensure your staff can quickly check that food is held at the right temperature, reducing the risk of human error.

This approach to food safety is especially helpful if you regularly work with high-risk TCS food items.

What is the minimum hot holding temperature requirement for...

Specific charts don't exist for these foods (yet), but here are the minimum temperature requirements for more popular hot holding foods in the food industry:

- Macaroni and cheese: The minimum hot holding temperature requirement for mac and cheese is 135°F or higher.

- Baked potatoes: The minimum hot holding temperature requirement for baked potatoes is 135°F or higher.

- Chicken strips or nuggets: The minimum hot holding temperature requirement for chicken strips and chicken nuggets is 135°F or higher.

- Fried shrimp: The minimum hot holding temperature requirement for fried shrimp is 135°F or higher.

- Shredded pork: The minimum hot holding temperature requirement for shredded pork is 135°F or higher.

- Hot soup: The minimum hot holding temperature requirement for hot soup is 135°F or higher.

- Pasta with Alfredo sauce: The minimum hot holding temperature requirement for pasta with Alfredo sauce is 135°F or higher.

As you can see, the 135°F (57°C) or higher figure is common for many foods across the board. So even downloading the general hot holding temperature chart should suffice in helping teams stay out of the temperature danger zone.

Food product temperature must be verified (and food safety software will help)

While hundreds of people every month download our free food safety templates, many of them end up using (or at least trying) FoodDocs' digital Food Safety Management System to simplify food safety task completion, verification, and more.

It takes paper-based systems and quickly digitizes them so that teams can more easily ensure food safety compliance, from monitoring to traceability.

Level up your temperature logging procedures

Hot holding, cold holding, refrigerators, freezers — whatever you need to log temperatures for, FoodDocs will support you.

You can use our food safety software's automatically generated logs or create entirely custom temperature logs based on your hot holding operation.

Whatever you decide, digital hot holding temperature logs will result in more accurate readings for two reasons:

- Smart notifications: Team members responsible for food safety tasks such as logging hot holding temperatures during a shift will get timely notifications so they never miss another log again.

- Corrective action prompts: If a team member inputs a hot hold temperature that's outside of your pre-defined acceptable range, the FoodDocs mobile app will immediately prompt them with corrective action instructions according to your food business's standards.

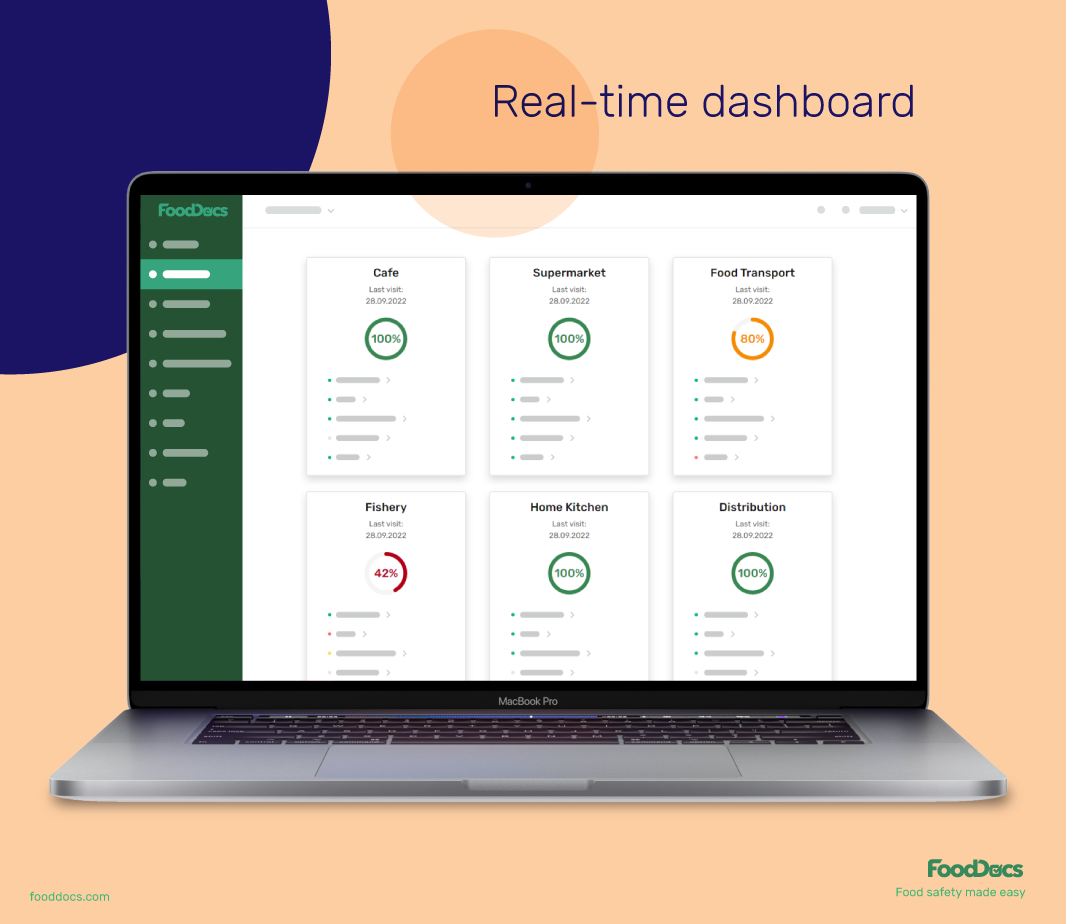

If you're the one responsible for your business's overall food safety compliance, the real-time overview dashboard will be a key part of your day. From there you get a high-level view of which departments or locations/units are in full or partial compliance.

Whether you’re on-site or remote, you can set up monitoring food safety tasks that always need to be verified once team members complete their entries. This feature is essential for food establishments that hold their food safety operation to very high standards.

See how the FoodDocs Monitoring and Traceability system work in this quick explainer video!

Hot holding temperature FAQs

How long can food stay in hot holding? What's the maximum hot holding time?

Food has a safe hot holding duration of up to four hours. Beyond that, food quality and safety begin to decline whether you're working with one chafing dish or multiple batches of food.

What’s the minimum temperature requirement for hot holding equipment?

The equipment used for hot holding should be set at 135°F (57°C) or higher as an optimal temperature range, depending on the food being held.

Green beans cooked for hot holding on a buffet must reach a minimum internal temperature of?

Green beens cooked for hot holding on a buffet must reach a minimum internal temperature of 140°F (60°C) in order to prevent dangerous bacteria growth that can cause foodborne illnesses.