Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

It is important to store and stack raw animal proteins prior to cooking properly because raw animal proteins have the potential to contain dangerous pathogens like Campylobacter, Clostridium perfringes, Salmonella, E. coli, Listeria, and other bacteria. These pathogens can be found on the surface of raw animal proteins as well as in their internal juices.

If they're stacked wrongly inside the refrigerator, their juices can drip or run down into other batches of food resulting in cross-contamination and foodborne illness. As a general requirement, all food handlers must know how should raw animal proteins be stacked before cooking.

Raw animal proteins may contaminate other foods in a refrigerator through drippings or contact.

It is crucial to store raw meat and poultry separately from other foods to prevent cross-contamination.

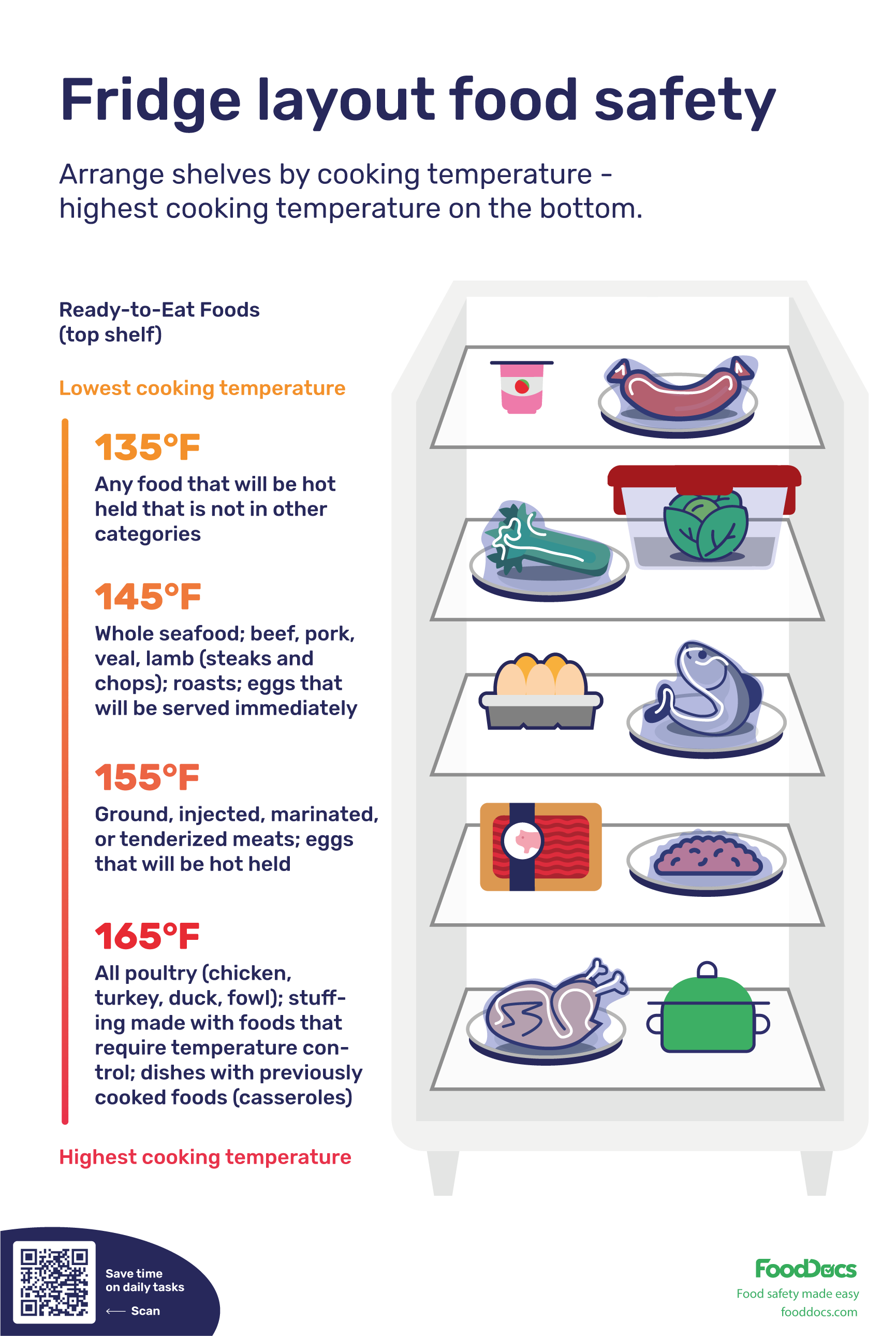

The stacking order of raw proteins in a fridge should be based on their internal cooking temperatures.

Proper storage and stacking of raw animal proteins reduce the risk of foodborne illnesses by minimizing the potential for pathogen growth.

Food handlers must be educated on how to correctly stack and store raw animal proteins to ensure food safety.

Misplaced or improperly stored raw animal proteins can leak harmful bacteria onto other food items, leading to contamination.

Separation and correct packaging of different types of raw animal proteins are essential to maintaining food safety.

Regular monitoring and documentation of storage practices help maintain compliance with food safety regulations.

Training and consistent practice of safe food handling techniques are crucial for preventing contamination and ensuring food safety.

WHAT WE'LL COVER:

Raw animal proteins must be stored separately from one another and from other food products such as ready-to-eat TCS food before cooking. These foods should never touch each other directly, even if you are using different types of packaging and containers.

Food handlers must know how to follow specific rules for stacking foods when stored in a refrigerator or an ambient temperature room to reduce the risk of causing foodborne illnesses.

Sources of animal proteins in the human diet include beef, pork, poultry, fish, and other meat from farmed or wild animals as well as eggs and milk. When we say “raw” animal protein, this pertains to the state of these food products being fresh or uncooked. Any of the mentioned animal proteins is a common ingredient in restaurants and even in individual houses.

Most of them are considered perishable or time and temperature control foods (TCS foods) because of their biological and chemical composition. They are considered under this category along with other foods such as sweet potatoes, leafy greens, rice, and fruits. As such, potentially hazardous foods must be properly stored in a refrigerator or freezer. Their composition makes them optimal for the fast growth of pathogens which causes deterioration of food quality and safety.

Raw animal proteins require specific food safety handling to prevent the growth of pathogens as part of food safety basics. The lean muscle tissue of farmed animals and birds would usually contain 71%-76% of water, 20%-22% content of protein, and 3%-8% carbohydrates and other minor components such as vitamins. These proteins are normally used in food establishments as appetizers or main dishes.

Raw animal protein can be easily contaminated during slaughter, processing, and transport. It can also happen during storage, may it be in a factory, establishment, or at home. If these raw animal proteins are not properly stored, spoilage and pathogenic organisms such as Salmonella, E. coli, and Listeria that cause foodborne illness can easily grow on them and contaminate others.

Most of these pathogenic organisms grow and multiply at a very fast rate in food left at room temperature. Storing raw animal protein or any meat package in the refrigerator (low-temperature preservation) can help prevent or control the growth of bacteria and maintain the product's quality and safety.

Frozen foods or cold foods are less likely to spoil fast, can stay fresh even for weeks or months, and would not cause any disease or health-related issues. This is assuming that the raw materials for food storage came from an acceptable source.

However, it is also important to know the proper stacking of different raw animal proteins (cuts of beef, pork, poultry, and fresh fish) because we do not want cross-contamination to happen within the storage equipment or on food contact surfaces. When improperly stacked, raw foods, even frozen meat, that may potentially have pathogens may come in contact with other ready-to-eat foods.

Raw foods will still undergo processing, whereas ready-to-eat foods will not get any additional time for cooking. Once the latter type of food gets contaminated, it can directly harm customers by causing foodborne illness.

Food handlers must avoid “drippings” or raw meat juices coming from raw materials in food storage such as pork meat to touch ready-to-eat TCS food like vegetables and cooked foods. This includes blood on meat boxes or original packaging. Yes, even properly cooked foods that are can be contaminated by pathogens from raw animal proteins and become hazardous foods. To do this, food must be stored and arranged properly as part of the many steps of food production.

Proper food storage can help prolong the shelf life of animal proteins for months and reduce unnecessary food costs from wastage. Use our freezer storage chart to teach food handlers how to stack raw animal proteins in a cooler.

Thank you for downloading free template!

Want to get a customizable HACCP template?

Or set up your food safety system in 15 minutes?

Raw animal meat should be stored on shelves based on its required internal cooking temperature and the extensiveness of cooking required.

What is this cooking temperature? It is the ideal correct temperature at which an animal protein must be completely cooked to be safe for consumption. Additionally, proper storage in refrigerator should always be followed as it is a basic rule of food safety. It can also help prolong the keeping periods of food and reduce the overall unit cost of the allotted budget for buying in bulk.

Raw products with the highest cooking temperature must be placed at the bottom of the refrigerator. This includes your whole and ground poultry meat and dinner leftovers. Whole cuts of raw beef, pork, fish, and raw ground meat must be stacked on the middle shelves, whereas ready-to-eat food products and other cooked products are placed on the top shelves. This can help prevent using hazardous foods as protein in diet or in dishes you serve.

It is important to follow this order during cold storage to avoid contaminating other contents in the refrigerator and only have safe food. The main thing that we do not want to happen is for these raw animal proteins to touch other foods such as ready-to-eat or any other fresh food. Once contaminated, it will be difficult to destroy some pathogenic organisms from these vegetables since they are commonly cooked using low temperatures or are usually eaten fresh.

Raw animal proteins should also be stacked separately from cooked food when stored inside your refrigerator. This is because bacteria from raw animal proteins can also contaminate cold, cooked food especially if it is not covered securely. It will be dangerous once a person decides to pre-heat the food and fails to thoroughly cook it again. If it was contaminated and eaten, the dangerous bacteria can cause serious illness.

That is why raw food must always be stored in a clean and properly sealed or airtight plastic container. The same thing should be done with cooked foods. These airtight containers must be solely used for storing food to avoid contamination. In cases when you are in a hurry or you do not have enough original containers, you can also use plastic wrap or aluminum foil to cover the meat or other types of food.

Any raw food, regardless of whether it is in a shallow plastic container, must always be placed at the bottom of the shelf.

The safest way to stack your raw animal proteins inside the fridge is based on their minimum temperature for cooking. Based on this information, whole cuts of raw beef and pork can be stored together on the middle shelves, below the top shelves where ready-to-eat foods are stored.

Make sure that beef and pork are properly wrapped in their original container or stored separately in a sealed container that is only up to three inches deep to avoid contamination. A piece of raw beef in pouch or a proper container will less likely contaminate others and cause the growth of bacteria in other foods.

Some thicker foods may require smaller containers to facilitate cooling. Even though they are both raw meats, it is still a custom food handling practice to separate them accordingly in different containers. For ground beef and pork, they must be stacked on a separate level. Undercooked ground beef packages can be placed below the shelves of the whole-cut meat.

Raw chicken and raw pork cannot be stored together since they have different target safe cooking temperatures. Frozen poultry and poultry products must always be placed on the bottom part of the commercial refrigerator whether they are whole cuts or not.

On the other hand, whole cut and ground pork are stacked on the middle shelves. The same as above, you also need to properly wrap or store them in a sealed container separately to avoid any bacterial contamination even though they are placed on different shelves.

If you have raw or uncooked meat and fish to be stored, then you can stack them together on the same shelves, but you need to consider if the meat is whole cut or ground. For whole cuts of raw meat, it can be stored together with your fish on the middle shelves, just below the top shelves for ready-to-eat foods.

Despite being allowed to store on the same shelf, they also need to be separated from each other by putting in a sealed container to avoid contamination. For ground meat and ground fish, however, they must be stacked on a different shelf than that of the fish. They must be placed below the shelves of the whole cut meat.

Unlike whole cuts of meat, more components of ground pork have been exposed to potentially contaminated factors such as during grinding and handling. This makes ground meat more prone to contamination and spoilage and increases its risk of cross-contaminating other foods.

The major factor to consider in storing raw animal protein is a safe temperature. Based on what has already been explained, it is important for food handlers to know the different “internal temperatures” and cooking times of raw animal proteins. This information can help food handlers identify the proper storing location of foods inside a clean refrigerator.

We also compare their cooking temperature with that of cooked foods, raw vegetables, and other food items to make sure that they are stacked separately to avoid any cross-contamination. It is only logical that food handlers must always keep foods that are ready to eat away from products that may contaminate them. Raw animal proteins will still undergo cooking, which may reduce the potentially present bacterial load.

Temperature is also one of the most important factors that can affect bacterial growth in food. Bacteria can easily grow on raw animal proteins especially if they are exposed to the temperature danger zone which is between 40 °F and 140 °F (4°C and 60°C). That is why it is highly advisable to immediately store raw animal proteins in the refrigerator and to make sure that a temperature of 40°F will be maintained.

Temperature control is an important operation as it is responsible for preventing the loss of quality of the raw animal protein and extending its shelf life. Refrigeration (chill) is part of the four guidelines of the United States Department of Agriculture, USDA to avoid contamination and keep food safe.

Having a better understanding of the effect of minimum temperature on raw animal proteins can help people store and protect their food from contamination. Technology and the creation of modern storage equipment will be meaningless if people do not know how to properly use them to their advantage.

Simple knowledge in stacking and storing aspects of food preparation actually protects customers from any food poisoning. Therefore, learning about the relationship between cooking and storage temperature, different food products and their shelf life, and different sources of contamination would support food safety.

Proper food storage is a constant task that needs to be done every day and monitored every minute in your food establishment. Doing so is a legal requirement and part of the proper rules to keep your food safe and your customers away from food poisoning.

Doing such a task multiple times a day can keep your employees away from other operations in your business. At times, quality may suffer if food handlers are not trained well to perform multitasking. Any food safety and quality practice cannot be an afterthought in food service.

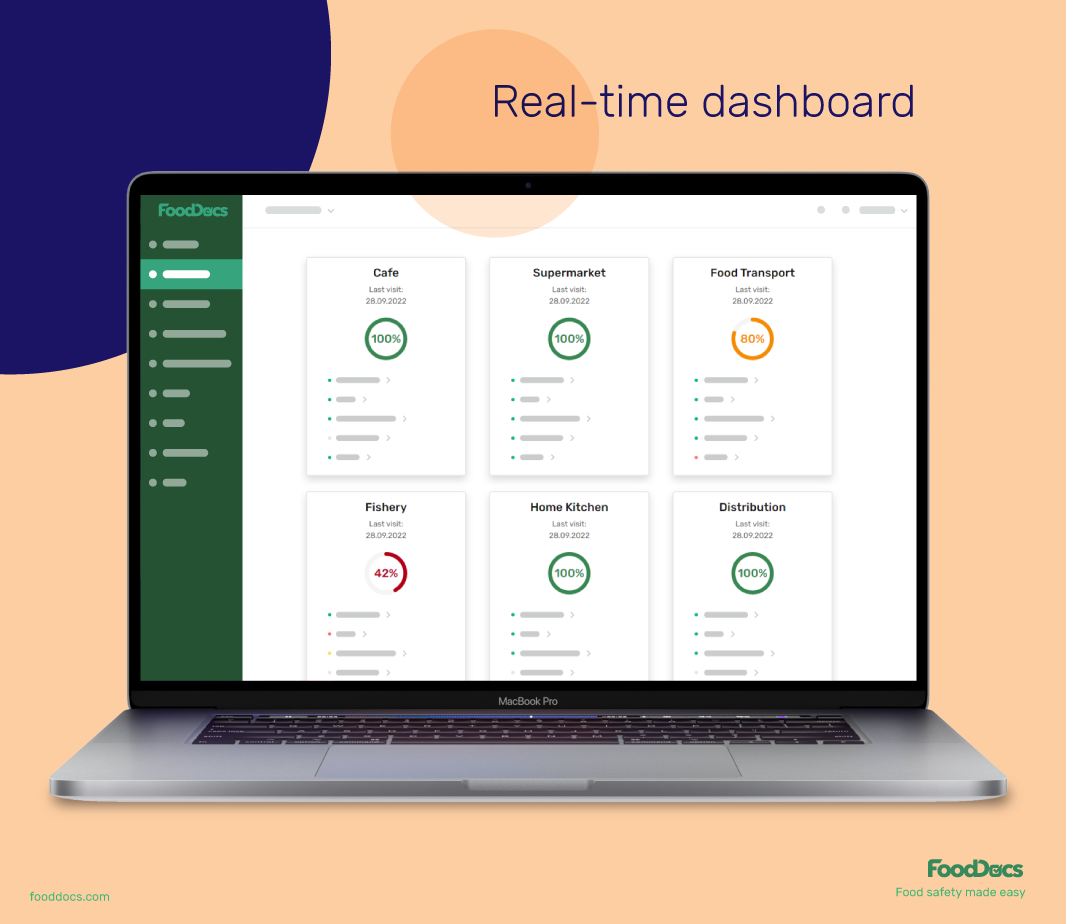

Luckily, our team at FoodDocs has created the best digital solution to help food employees and managers handle all aspects of food safety without having to sacrifice other aspects of your business. Using our digital Food Safety Management System, you can get automatically generated digital food safety documents.

When you use our digital solution, you can get the following features:

Our monitoring forms also feature detailed instructions to help your team understand how to perform the tasks. This feature can also help you or your food safety manager in onboarding your new employees for training on food safety basics.

In addition to food safety features that will help every food handler, we also have digital solutions for food safety managers. We can help you manage your team more efficiently:

The best part about our digital solution is that you do not have to be a tech wizard just to generate a whole digital FSMS. All you need to do is to answer a few questions and our system can automatically generate the whole digital FSMS using artificial intelligence. The whole process would only take an average of 15 minutes to finish!

If you want to experience all of our services and try them for yourself, we offer a free, 14-day trial. Get to know how we have helped more than 20,000 food businesses worldwide maintain food safety compliance now.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...