Mastering Restaurant Sanitizing: Best Practices for Kitchens and Dining Areas

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

If you’re looking for an effective GMP compliance software, start with this curated list.

In the food manufacturing industry, businesses adopt international standards such as Good Manufacturing Practices (GMP), as developed by the Food and Agriculture Organization of the United Nations’ Codex Alimentarius, to protect their customers.

From food safety documentation and employee training to food handling and facility cleanliness, GMPs help food manufacturers ensure their food products’ safety, quality, and consistency.

Now imagine maintaining all that food safety management information with pen and paper…

With all the employee records, standard operating procedures, and monitoring and traceability logs required to get and stay compliant, maintaining a paper-based GMP food safety management system (FSMS) is near impossible.

Thankfully, GMP software solutions exist and you can learn more about the best ones below.

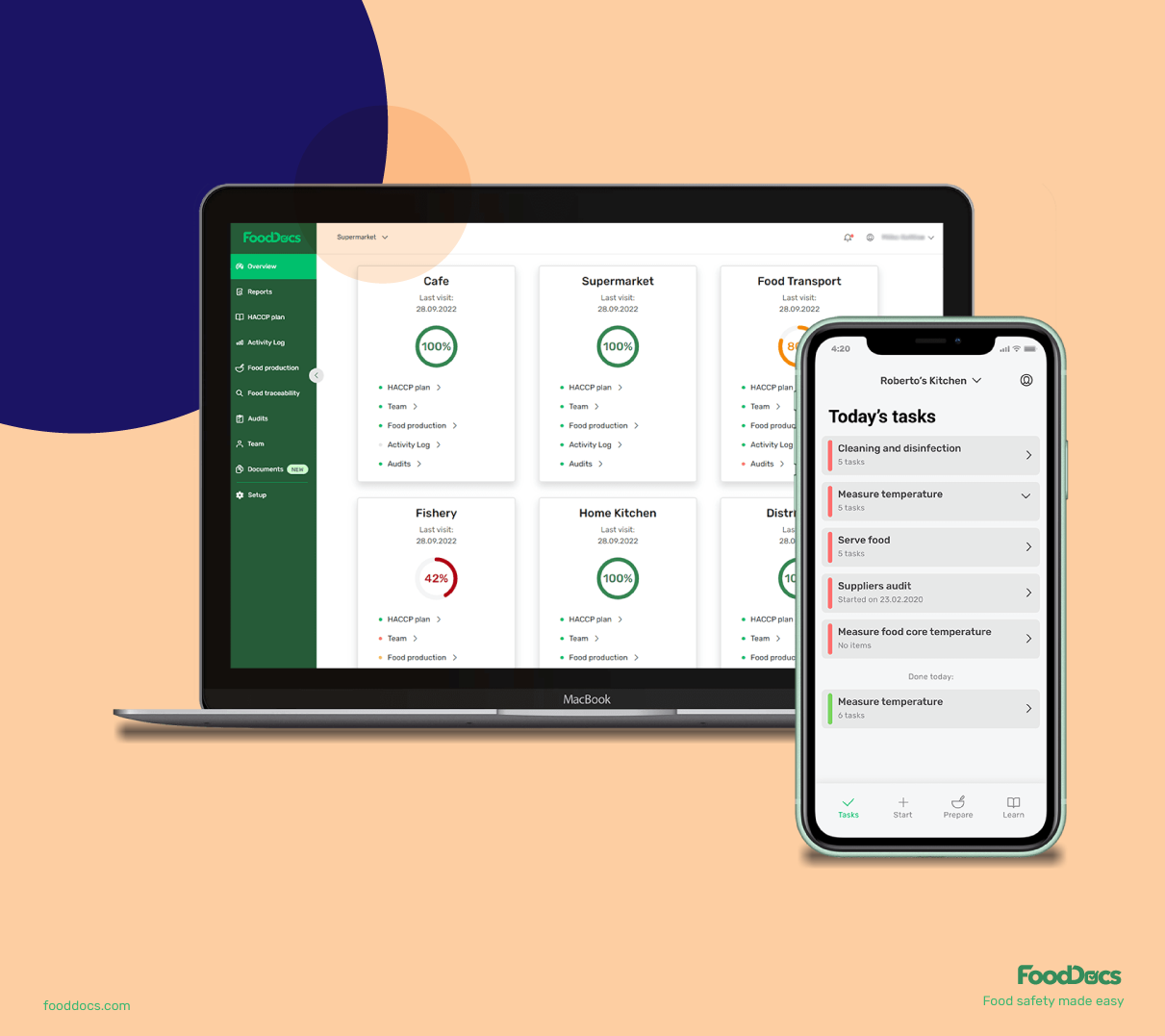

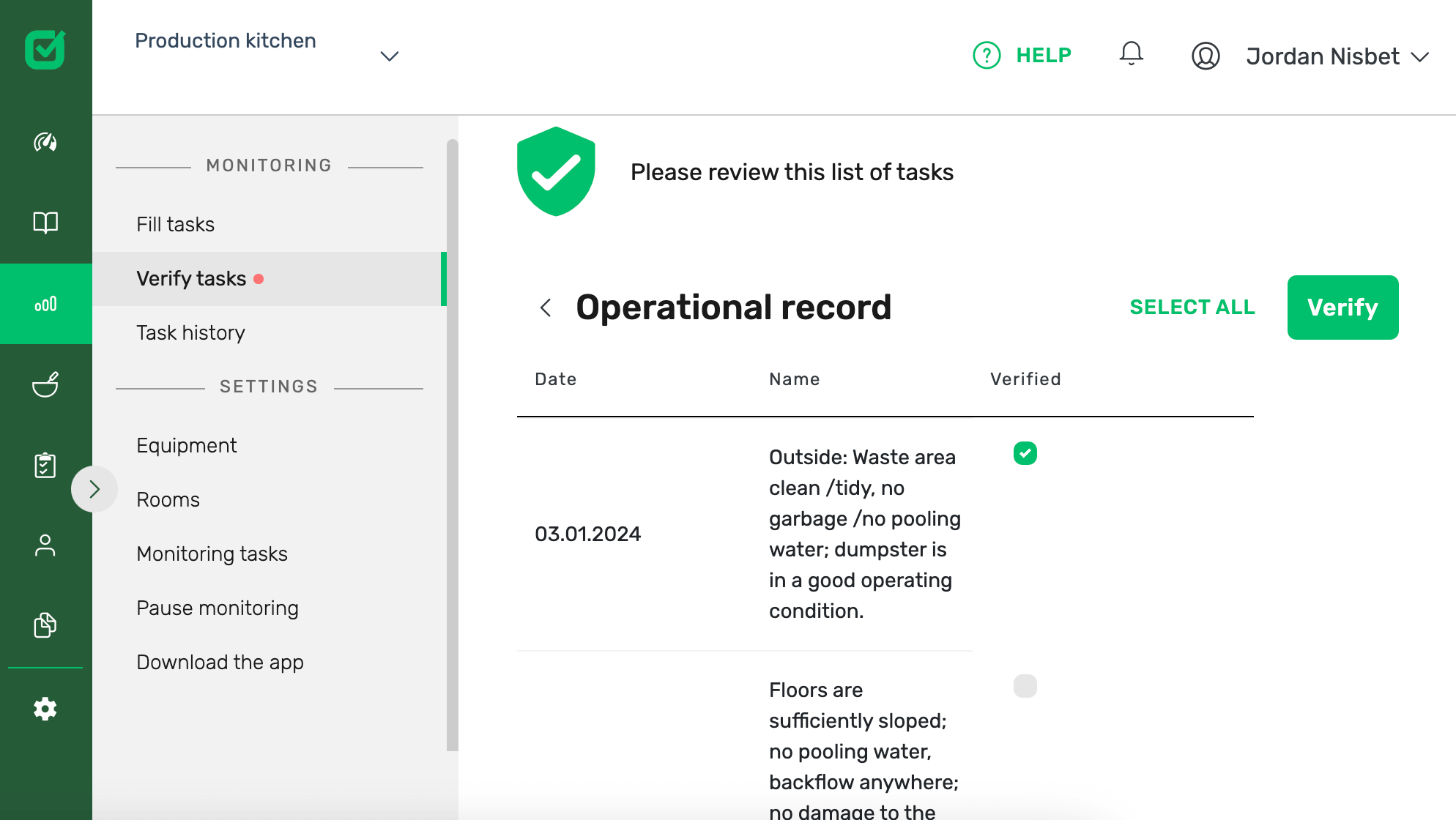

FoodDocs offers a comprehensive food safety management system tailored to help food manufacturers comply with GMP standards. The software is designed to simplify the regulatory compliance process through automated workflows and real-time monitoring. FoodDocs is an especially great fit for small to medium-sized food businesses looking for a cost-effective solution with an intuitive interface to manage their GMP food safety practices.

Free trial: 14 days

Pricing: $250/month

Available on: Web, iOS, Android

MasterControl provides a robust quality management system (QMS) that helps food businesses meet GMP requirements through comprehensive quality control and compliance management. The software is ideal for medium to large enterprises in the food industry that require a scalable solution to manage complex compliance processes.

Free trial: Available on request

Pricing: Not available on website ($25,000/year via Capterra)

Available on: Web

Tulip connects frontline manufacturing operations to GMP compliance, providing visibility and control over the manufacturing process. The software is particularly beneficial for medium to large food manufacturers looking for a flexible solution that integrates seamlessly with existing systems.

Free trial: Not available

Pricing: Starting at $100/month

Available on: Web, iOS, Android

FoodReady offers a comprehensive solution for GMP compliance with features designed to simplify the documentation and management of food safety practices. The software is particularly suitable for small to medium-sized food manufacturers looking for a user-friendly compliance software with in-house consultants.

Free trial: 14 days

Pricing: Not available on website

Available on: Web, iOS, Android

If you're interested, dive deeper into our FoodDocs and FoodReady comparison.

Safefood 360 provides a digital platform for food safety management, focusing on GMP compliance and accurate quality control. The software is ideal for medium to large food manufacturers that require a comprehensive solution for managing complex compliance requirements.

Free trial: Not available

Pricing: Not available on website

Available on: Web, iOS, Android

ETQ Reliance is a flexible QMS that helps food manufacturers manage GMP compliance through comprehensive quality processes. The software is suitable for medium to large enterprises in the food industry that need a scalable and customizable solution for managing quality and compliance.

Free trial: Not available

Pricing: Not available on website ($25,000/year via Capterra)

Available on: Web

TGI provides an ERP solution with built-in GMP compliance features tailored for the food industry. The software is ideal for small to medium-sized food manufacturers looking for an integrated solution to manage both operational and compliance requirements.

Free trial: Not available

Pricing: Not available on website

Available on: Web

SafetyCulture offers a platform for managing GMP compliance with a focus on inspection and quality assurance. The software is particularly suitable for small to medium-sized food manufacturers that need a user-friendly and flexible solution for maintaining high standards of food safety and quality.

Free trial: 30 days

Pricing: $24/seat/month (free version available dependent on users)

Available on: Web, iOS, Android

GMP software in the food industry is designed to help manufacturers comply with Good Manufacturing Practices by automating and managing various aspects of food production to ensure product safety and quality. This includes managing documentation, monitoring production processes, conducting GMP audits, and ensuring traceability.

GMP-compliant software ensures that all procedures are standardized, recorded, and compliant with regulatory requirements, ultimately helping to produce safe and high-quality food products.

Automated workflows reduce manual efforts and streamline processes, which leads to increased productivity and fewer errors. Deciding to start digitizing documentation and automating routine tasks with the help of GMP software minimizes (if not eliminates) the need for manual data entry and paper-based processes. All of which saves time while reducing the risk of human error.

GMP software can automate complex processes such as scheduling inspections, tracking corrective actions, and generating compliance reports, allowing employees to focus on more critical tasks that help grow the business.

Consistent adherence to regulatory requirements through automated compliance tracking and documentation ensures that food products meet safety standards. GMP software provides real-time alerts and reminders for compliance-related tasks, ensuring that nothing is overlooked. It also maintains up-to-date records of all compliance activities, making it easier to demonstrate adherence to regulatory requirements during audits.

Ensuring that all processes are standardized and documented with GMP-compliant software helps food manufacturers maintain continuous compliance with industry standards and regulations.

Real-time data collection and analytics provide insights into production processes, helping to identify and address issues promptly. Many GMP software solutions offer different types of dashboards and reports that highlight key performance indicators and potential areas of concern. This visibility enables managers to make informed decisions quickly, based on accurate and current data.

Identifying trends and patterns in production data will help your business proactively address issues before they escalate.

Detailed records and traceability features ensure that all ingredients and products can be tracked throughout the supply chain, enhancing accountability. GMP software provides end-to-end traceability, from raw material sourcing to final product distribution. This capability is crucial for quickly identifying and isolating any issues that arise, such as contamination or recalls. Especially in the context of FSMA 204 which requires that you provide the FDA with relevant recall data within 24 hours of their request.

Maintaining detailed records of each product batch, including production dates, lot numbers, and supplier information, businesses can increase transparency and accountability at every stage of the food supply chain.

Food businesses should always try to be optimizing their bottom line. Using GMP compliance software is one of the ways they can reduce errors, food product waste, and rework. As a result, food manufacturers benefit from lower operational costs and while preventing costly recalls or non-compliance penalties.

GMP software will also improve process efficiency and product quality, which will likely reduce food waste while increasing cost savingsThe ability to quickly address and resolve compliance issues also reduces the financial impact of potential non-compliance.

The ability to monitor production processes in real-time ensures that any deviations can be detected and addressed immediately. Real-time monitoring provides continuous oversight of critical control points and other key metrics, allowing for instant detection of anomalies or non-compliance issues.

This capability helps prevent minor issues from becoming major problems, as corrective actions can be implemented without delay. Maintaining constant vigilance over production processes will help businesses ensure consistent product quality and safety.

Automatically generating and updating GMP-required documentation helps maintain accuracy and reduces the burden on staff. GMP software automates the creation and maintenance of essential documents, such as Standard Operating Procedures, electronic batch records, and audit reports.

This automation ensures that all documents are consistently formatted, up-to-date, and easily accessible. By reducing the reliance on manual documentation, businesses can improve accuracy and efficiency, making it easier to meet regulatory requirements, pass audits, and get your GMP certification.

Facilitating internal and external audits through scheduling, tracking, and reporting helps ensure continuous compliance. GMP software provides tools to plan, execute, and document audits, streamlining the entire audit process. This includes automated scheduling of regular audits, tracking the progress of audit activities, and generating detailed audit reports.

If you start maintaining a comprehensive record of all audit activities and findings early on, businesses can identify areas for improvement while demonstrating compliance — which regulators appreciate.

Allowing certain users to manage compliance tasks from any device ensures that GMP practices can be maintained on the go. Mobile access enables employees to perform inspections, complete digital checklists, and access critical documents from smartphones or tablets.

This flexibility is particularly valuable for businesses with multiple locations or remote operations, as it ensures that Food Safety or Quality Managers can manage compliance tasks in an efective and timely manner, regardless of location.

GMP-compliant software that seamlessly integrates with other business systems allows for a unified approach to managing operations and compliance, reducing duplication of effort, and improving data accuracy for things like fridge and freezer temperature monitoring.

Consolidating information from multiple sources will give businesses a holistic view of their operations, leading to better decision-making and more efficient processes. Integration capabilities also ensure that all relevant stakeholders have access to the information they need, promoting a strong food safety culture and consistency across the organization.

As you explore the hopefully-smooth transition from a paper-based system to digital solutions, we hope the details above make your search for the best GMP software for your food manufacturing business easier.

The best thing you can do is to experience the GMP food manufacturing software for yourself. What does that look like?

Time is scarce and doing these things will help you make informed decisions and ensure that your business remains compliant with GMP standards.

Master restaurant sanitizing with clear steps for kitchens and dining areas. Learn methods, checklists, and procedures to keep your team safe and...

Learn challenges healthcare foodservice teams face today and key food safety practices to protect vulnerable patients. Get a free healthcare leader...

Learn what Standard Operating Procedures (SOPs) are and how to write effective SOPs that ensure consistency, efficiency, and safety in your...