HOW TO USE A MEAT THERMOMETER?

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

How to use a meat thermometer

A meat thermometer is every food handler's handy best friend for the perfect cooking process for an expensive piece of meat for juicy steaks and other delicate dishes. Not only is it necessary to use a meat thermometer to perfect the desired doneness temperature, but it is also needed to ensure food safety. Not all customers want a medium-rare or rare levels of doneness on their steak because of health reasons. To protect such customers from foodborne illnesses, you need to ensure that your food handlers know how to use a meat thermometer properly.

Properly cooking meat ensures that the potentially existing pathogens are removed. Every year, at least 600 million people get sick from foodborne illnesses. A large portion of these foodborne illnesses is caused by inadequate food safety practices. Proper cooking and temperature reading are crucial operations when serving different cuts of meat in every food business. Food handlers are required to understand the principles of using different types of thermometers, including analog and digital thermometers, for reading the current temperatures of food.

Learn how to properly use an accurate thermometer for your food business through this article and download our informative guide.

What is a meat thermometer guide?

A meat thermometer guide is a useful tool that will serve as a reference for food handlers on how to use an accurate meat thermometer properly. Contrary to other food thermometers, a meat thermometer is made to withstand very high temperatures. Some meat thermometers were even built to withstand being inserted in the meat while cooking.

To ensure accurate measurements of temperature and safe cooking temperatures, food handlers must be guided on how to use a meat thermometer. Different cuts of meat such as beef, lamb, pork, poultry, and even seafood are associated with foodborne pathogens and diseases. This category includes ground meat, which requires even harsher heating. Their nature and composition of being rich in nutrients make them susceptible to the growth of dangerous bacteria.

A good example of this is the association of raw chicken with Salmonella. Serving undercooked or raw poultry may potentially cause a wide foodborne illness outbreak. Proper cooking can inactivate this bacteria. As such, food handlers must be aware of how to determine whether the cooking process is enough or needs more cooking time.

Use our smart meat thermometer guide to orient food handlers on how to get accurate thermometer readings.

Who needs a meat thermometer guide?

All food handlers working in a restaurant, food truck, cafeteria, retail food business, and even a deli shop will benefit from learning how to use a meat-specific thermometer. Every food business that deals with serving meat are required to train their employees on how to properly cook foods to protect vulnerable customers. To do this, you can use our trusty meat thermometer guide to demonstrate and orient the dos and don'ts of a thermometer for meat.

What is the core temperature of foods?

The core temperature refers to the wide range of safe temperatures at the thickest portion of food when being cooked. The core of food is the farthest place the heat source has to reach to ensure even cooking. Every type of meat has its own recommended custom temperature (and every part of a meat might have a different recommended internal temperature, such as pork).

As previously mentioned, meats are often associated with a particular foodborne pathogen, such as harmful microorganisms. To ensure that these bacteria are killed, the heat you apply to food must reach the wide range of the core or center of the food.

Accurate readings and correct temperature registers are crucial in ensuring the target core temperature is reached. Using a properly calibrated meat thermometer, food handlers can monitor if they have already applied enough heat to the meat that they are cooking. An inaccurate temperature reading can cause a widespread foodborne illness outbreak.

Why is measuring meat cooking temperature important?

Heat inactivates the present pathogens in meats. These pathogens have a particular maximum temperature threshold, which, when exceeded, will kill them. Target internal cooking temperatures are based on these thresholds, and each type of meat has a particular cooking temperature range. Food handlers must always follow this minimum temperature requirement to keep customers safe.

Constant measuring and monitoring of the cooking temperature will help food handlers ensure whether the target internal temp has been reached or not. Undercooking foods increases the risk of causing foodborne illnesses, whereas overcooked meats lose their quality.

Additionally, measuring the cooking temperature using a type of meat thermometer can help accurately achieve the desired level of doneness before removing food from heat source. Constant monitoring can help you keep track of the cooking progress for the internal temperature of beef for making steaks.

How often should you measure meat internal temperature?

Most meats have an established time of cooking. Use this information to estimate when to check the internal temperature of your meat. The frequency of checking will depend on how close you already are to the target exact temperature.

Alternatively, some analog meat thermometers have been manufactured to be oven-safe. For such types of food thermometers, you can insert the metal probe at least 2 inches deep and correct angle for reading into the thickest part of the meat and leave it on. For some types of meat, such as poultry, the chicken breast is the most advisable to insert the digital probe thermometer.

Using this type of thermometer, you can perform consistent temperature monitoring for the internal temperature of your meat dish or other combination dishes. Record all temperature readings in your cooking temperature log as a reference for safety.

What equipment do I need for measuring meat internal temperature?

A meat thermometer is the essential kitchen tool or piece of equipment for measuring the proper temperature of the meat. This type of dial thermometer was designed to withstand the very high temperatures of meat products while cooking. Basic probe thermometers are a type of kitchen tool made of stainless steel. More convenient options and models such as an instant-read meat thermometer or digital versions with a digital display are also available in the food industry.

Most types of meat thermometers only have an easy-to-read display for the temperature reading, whereas others conveniently have markings of preset temperatures. Some pricier probe thermometers feature a digital screen that shows other factors such as the humidity level of the food's environment. The metal probe has an indicator for how deep the insertion must be to get an accurate reading. To ensure that you will only get accurate temperature readings, always schedule your cooking thermometer calibration and record every calibration reading.

Use the appropriate monitoring logs to record both calibration and meat internal temperature readings. Get the most important food safety documents from our HACCP plan template hub. The best part about our safety tools is that they are all free! Use our handy guide to cooking temperatures for meat from this list of food safety documents.

To help you understand more about how to use a meat thermometer, here are a few frequently asked questions about this topic:

Do I leave the meat thermometer in while cooking?

There are specialized, high-quality meat thermometers that you can leave inside the food while cooking. This type of meat thermometer is specially designed for oven cooking. To know whether your meat thermometer is compatible with this operation, check the original container for the manufacturer's directions or contact your thermometer supplier. A leave-in thermometer offers convenience for food handlers and can verify the readings of an accurate oven thermometer.

When should you insert a meat thermometer?

For oven-safe thermometers, you can insert the thermometer at the proper placement before putting the food inside the oven. Deep-fry thermometers are as sturdy as oven-safe ones. For other types of thermometers, such as digital meat thermometers and lesser quality analog thermometers, you should only insert the thermometer probe towards the end or a couple of minutes before the end of cooking. This operation is done to verify whether the target internal temperature has already been reached or the dish needs more cook time. The digital readouts will reveal the readings in a fast turnout.

How do you accurately read a meat thermometer?

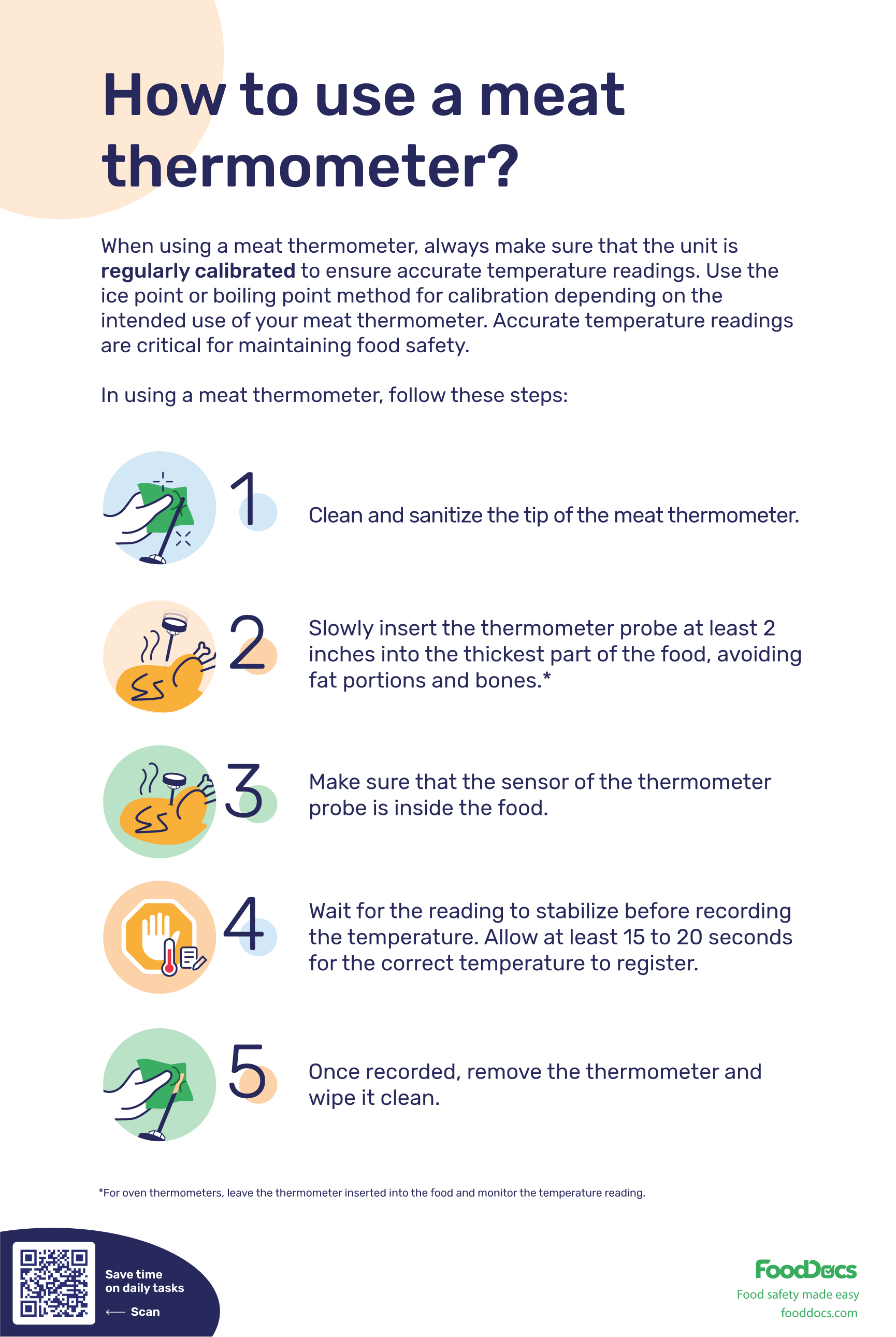

When using a meat thermometer, always ensure the unit is regularly calibrated to ensure accurate temperature readings. Use the ice water or boiling water method as a calibration option depending on the intended use of your food thermometer. Accurate temperature readings are critical for maintaining food safety.

Double-check if your meat thermometer is heat-proof or if it can withstand oven temperatures.

In using a meat thermometer, follow these steps:

-

Clean and sanitize the tip of the food thermometer after removing the stem sheath.

-

Slowly insert the thermometer probe at least 2 inches into the thickest part of the food, avoiding fat portions and bones.**

-

Make sure that the sensor of the thermometer probe is inside the food.

-

Wait for the reading to stabilize before recording the temperature. Allow at least 15 to 20 seconds for the correct temperature to register. Record the temperature readout.

-

Once recorded, remove the thermometer, wipe it clean, and return the protective sheath.

**For oven thermometers, leave the thermometer inserted into the food and monitor the temperature reading.

How far do you insert a meat thermometer?

Most meat thermometers have a marker on their metal probes that indicates the required depth for inserting the thermometer into the meat. Ideally, you need to insert the thermometer probe at least two to two and a half inches into the thickest part of the meat you are cooking.

How can I help my team remember to measure meat cooking temperature?

As meat cooking temperature monitoring is a very critical operation in any food business, food handlers must always be trained to perform it. They must also always be informed when to monitor the temperature and how to record the temperature readings. It does not matter whether you have the top-of-the-line digital instant-read thermometer if you do not know how to use it properly.

At FoodDocs, we have developed a digital solution to solve every temperature monitoring operation for food businesses. Using our digital solution, you can get smart monitoring forms with detailed instructions on performing food handling tasks. With this solution, you can cover your monitoring objectives and onboarding process without the extra hassle. How can we help you, and what do we provide for your team?

Here is a list of benefits you can get from our digital solution:

-

We offer a digital solution through smart notifications to help food handlers remember when to take the temperature. With our mobile application, our system can send smart alerts to remind an employee of a scheduled task. Additionally, you can use this feature to note highly perishable foods in stock.

-

Every monitoring form we generate or you features detailed instructions on how to perform the task. This feature was made to help guide every food handler and ensure that the food safety operation is performed correctly.

-

Using artificial intelligence, our system can refill your monitoring logs based on previous data entries to improve accuracy. This feature saves a significant amount of time for your team. In addition, these logs are intuitive that they can give temperature alerts in case of non-compliance.

In addition to features for food handlers, our digital solution was also built to help food safety managers:

- Our digital Food Safety Management System solution takes 15 minutes to set up. All you need to do is answer a few basic questions, and our system will automatically generate all important food safety documents for you.

- You can also get a real-time dashboard that you can use to save at least 20% of your time managing your team. With this feature, you can have an overview of your everyday operations and easily identify which areas need more attention.

- With our digital solution, you can also get a digital cloud space to store all your digital documents. Store and access all documents in one place for convenience and save time on finding the documents.

Our digital solution was built to make food safety compliance an easy task for all food handlers and help protect customers from food poisoning and related issues. When you sign up with us, you are moving one step forward to sustainability by removing all paper-based monitoring operations.

Get your comprehensive digital FSMS in an average of 15 minutes. Experience our product features firsthand by availing of our free, 14-day trial.