TEMPERATURE LOG SHEET PDF | FREE TEMPLATE

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

Temperature Log Sheet: What Is It?

A temperature log sheet is perhaps the most widely used checklist to monitor food safety in the food industry. It is an essential piece of paperwork in your food safety management system that helps to ensure safe food processing and storage.

A temperature log sheet serves as a monitoring form and a verification procedure for steps that need any type of corrective action in your food safety plan.

Key takeaways:

- Temperature log sheets are one of the most widely used monitoring checklists in the food industry.

- Temperature logs are critical to ensure safe food processing and storage.

- There are many types of temperature logs such as for food, refrigerators, coolers, and freezers.

- You can make a temperature log sheet manually, or use a digital one. Just make sure it includes if you choose to make one yourself on paper or digitally, make sure it includes: time of recording, actual temperature, target temperature, and date of recording at the very least.

- It's essential to keep your food at the required temperature throughout the whole supply chain, including transportation and storage.

- The longer food stays in unsafe temperatures or the temperature danger zone, which is between 40°F and 140°F, the more dangerous it becomes.

- Temperature fluctuations during cold storage and transport can be critical to highly perishable foods such as raw meats that are ground or whole as well as for fruits and vegetables.

- To prevent food safety legal issues, when monitoring temperatures, make sure you use a reliable food thermometer, schedule regular calibrations, and keep a separate log for each device.

- The frequency of measuring and registering your various food and equipment's temperature can be different depending on your company's profile and approach to food safety.

- FoodDocs is a food safety monitoring software that makes logging temperatures easy.

Safe temperatures play an important role in the food industry. Cold temperature is mostly used to extend the shelf-life of foods, whereas high temperatures are used for cooking. As a food manufacturer, it is one of your many tasks to ensure that the acceptable temperature levels for these processes are maintained at all necessary times.

WHAT WE'LL COVER:

3 Common types of temperature log sheets

1. Food Temperature Log Sheet

A food temperature log template can be applied for monitoring temperature on various booking methods, whether hot or cold. Food workers responsible for handling food sensitive to temperature can use this temperature log template to perform regular checks more efficiently.

2. Refrigerator Temperature Log Sheet

You can also use a refrigerator temperature log template to monitor fridge (and freezer) temperatures as well as pantries and delivery vehicles.

3. Cooler Temperature Log Sheet

The same applies to equipment such as walk-in coolers. Using cooler temp logs gives your team the ability to easily and accurately monitoring temperatures.

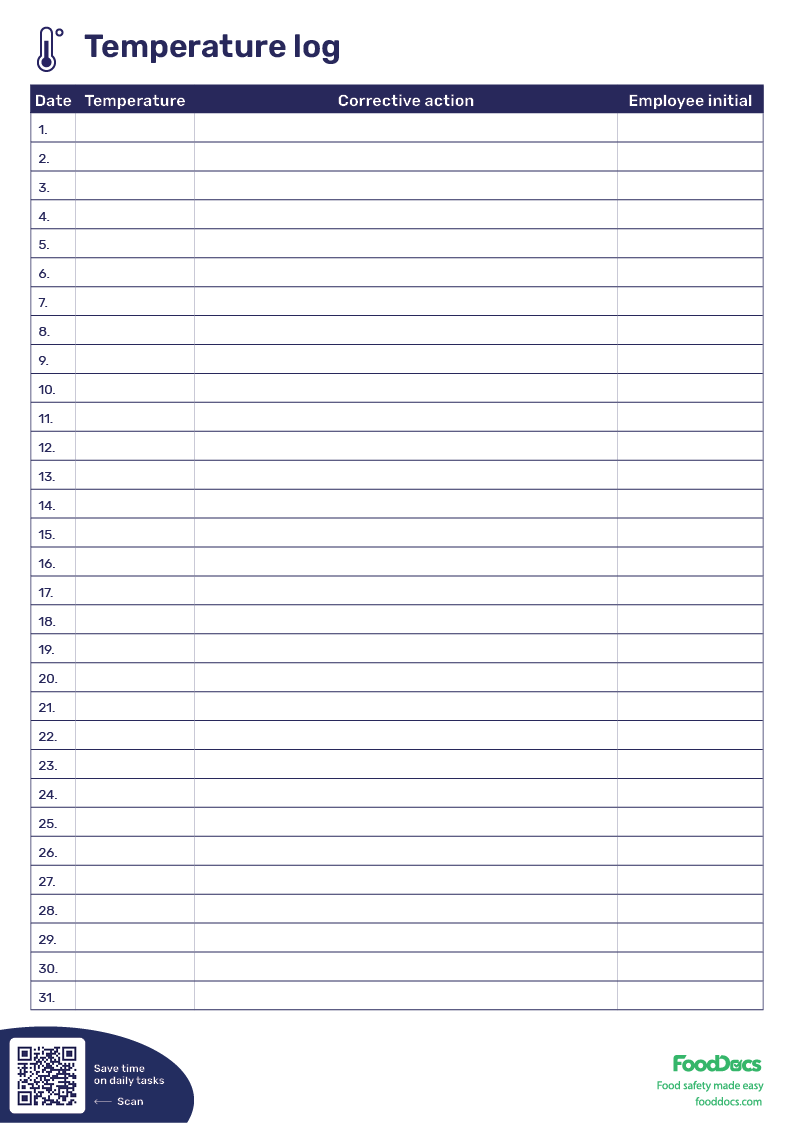

Whether you're using this temperature log sheet PDF for food or refrigerator and freezer temperatures, important information such as time of recording, actual and target temperature, and date must all be present.

In this article, we will guide you through the importance of a temperature log sheet for food business operations such as refrigerated storage and transport.

How to make a temperature log sheet?

Thankfully, you don't have to! Download the temperature log template we've provided for you above and start monitoring temperatures fast.

However, as we mentioned previously, if you choose to make one yourself on paper or digitally, make sure it includes:

- Time of recording

- Actual temperature

- Target temperature

- Date of recording

Why is the temperature log sheet important?

Ensuring that the required temperature is maintained is one of the basic food safety rules that all food businesses need to follow. It's essential to keep your food at the required temperature throughout the whole supply chain, including transportation and storage.

As soon as the temperature falls out of the established standard range, the number of pathogens grows in the food and the likelihood of causing foodborne illnesses due to unsafe food increases.

The longer food stays in unsafe temperatures or the temperature danger zone, which is between 4°C and 60°C, respectively, the more dangerous it becomes. At this temperature range, pathogens are most active. A slightly higher storage temperature over a couple of hours is not a critical safety issue for vegetables but can be extremely dangerous for fish and meat products.

Can you imagine ordering a salmon-sushi that includes raw fish and has been kept in a broken fridge? The temperature log template helps to prevent foodborne illnesses and protects your business.

Using cold storage or refrigerated transport vehicles preserves the food longer because microbiological activities are slowed down, if not stopped. In addition, most common microbiological pathogens cannot survive freezing temperatures and their multiplication is slowed down in chilled conditions.

In freezing conditions, water becomes unavailable for microorganisms to use. Maintenance and verification procedures for keeping the prescribed low temperature in refrigerators are vital to control food safety.

Temperature fluctuations during cold storage and transport can be critical to highly perishable foods such as raw meats that are ground or whole as well as for fruits and vegetables. As soon as the temperature rises because of faulty refrigeration, the inherent microorganisms in these products get the chance to recover and multiply.

If left unmonitored and unresolved, this can cause the likelihood of exceeding standard levels to increase.

Similarly, a temperature log sheet is also needed when it comes to thawing. Your product must be uniformly thawed to prevent the rapid multiplication of microorganisms on the surface of your product and prevent exposure to a contaminated environment.

Using a temperature log sheet, your team can monitor whether the standard conditions are being met and apply corrective actions in case of loss of control.

What to keep in mind when registering refrigerator temperature logs?

Measuring the fridge's temperature might seem like a piece of cake, but when your team has to fill more than 20 refrigerator temperature logs every day, like in most food service companies, it may become a real pain. Keeping a fridge and freezer temperature log sheet helps you organize the information you need and makes it easier for you to remember what information you need when monitoring.

To prevent food safety legal issues, here are some tips when monitoring temperature:

-

Use a reliable thermometer that measures accurate temperature. Most fridges and freezers have temperature displays, so you only need to check and register the refrigerator temperature log sheet.

-

Schedule regular calibration procedures for built-in thermometers as well as hand-held ones to ensure that all data entries are accurate.

-

Make sure that the thermocouples are protected from any obstructions that can cause inaccurate temperature measurements.

-

Keep a separate temperature log documentation for each device within the facility to avoid confusion.

-

Make sure that all temperature logs are properly labeled and have all the information you need. Standards must also be written adjacent to the monitored temperature to serve as a reference value for verification.

-

Keep fridge temperature logs as close as possible and make sure that the correct fridge and freezer temperature log sheet is in place. This way, it's easy to notice for your team.

-

Store your temperature logs according to your food safety management system. Temperature log sheets are commonly stored and filed for around 1-3 years.

-

Always record the correct date, time, refrigerator number, and temperature.

To help you record all the important information in terms of cooking and proper storage, you need to use a temperature log sheet that's versatile and can accommodate all the information you need.

Use our free temperature log sheet and print it out for your whole team. This free temperature record sheet template is just one of our many useful food safety documents at FoodDocs. you can head over to our food safety templates hub for more templates, checklists, posters, and advisories for food businesses.

How often do I need to check the temperature in fridges and freezers?

Depending on your company's profile and approach to food safety, the frequency of measuring and registering your freezer's temperature can be different. Here are some considerations when establishing monitoring procedures for your temperature logs.

Level of risk

The higher the food safety risk, the more often you need to check your freezer's temperature. In some companies, it's either once or twice a day, or it can even be once per week. High-risk or time/temperature control for food safety foods (TCS foods) includes but is not limited to products with eggs, low-acid foods, raw meats (whole and ground), milk, prepared vegetable salad, and fish. These foods require cooler temperatures to remain wholesome.

Weather conditions

In some countries, the frequency of monitoring can also be based on the weather, season, or climate and the insulation of your storage facility. During excessively hot weather, refrigerators usually take longer to reach the correct temperature levels. As such, temperature monitoring must be done more frequently.

Calibration and integrity of freezers and thermometers

Frequency can also depend on the calibration of your refrigerators, thermometers, and thermostats. As much as it is highly unadvised to use faulty or uncalibrated thermometers, there are unavoidable circumstances that lead to such situations. In this case, a backup manual thermometer must be used to double-check the reading and the frequency must be increased.

If your freezers or refrigerators are not consistently functioning well, the frequency of monitoring must also be increased until maintenance and repairs are applied to your equipment.

Size of refrigerators and storage area

For larger storage areas, the frequency of monitoring can also sometimes depend on the location of the fridge and freezer. A regular temperature mapping every 2 to 3 years of the whole storage facility is advised to determine which spot receives the lowest and highest temperatures.

Is the temperature log sheet mandatory?

Yes, the temperature log sheet is mostly mandatory for any food handling business. In addition, cold storage using refrigerators, chillers, and freezers is a common critical control point for food businesses that deal with raw meats and other perishable goods.

Your HACCP food safety program must include setting critical limits, monitoring forms, and corrective actions related to the level of temperature control. To satisfy these requirements, a proper daily temperature log sheet is mandatory.

During regulatory agency visits for scheduled audits, temperature log documentation is reviewed. Improper and inaccurate record-keeping procedures can get your business in trouble.

That's why your cooking log template and freezer temperature record sheet have to be ready for auditing at any time. An up-to-date food temperature log sheet is good evidence that your facility takes food safety seriously and is ready for a food safety inspection.

Even if there are no regular audits, a fridge and freezer temperature log sheet is still mandatory to ensure that you are producing safe food. Failure to apply the established standard limits means that food safety issues will arise and that food hazards will not be controlled.

Even if you can produce safe foods, food items that have been exposed to very low freezing food temperatures tend to lose their correct consistency and can damage their quality. This tells you that applying standard parameters and monitoring cold temperatures in storage facilities is important for food safety and quality.

Using smart fridges and IoT sensors with your temperature log template?

Many companies use smart fridges or IoT (Internet of Things) sensors nowadays. This means that the fridge or freezer's temperatures will automatically be sent to the maintenance team when the temperature is out of range. It seems convenient, but there are some points you should keep in mind:

- Relay of information must be programmable to first reach the quality assurance inspector and then the other involved employees. As soon as the critical limit is breached, corrective action must be applied as soon as possible - whether to close the door to reach the correct temperature level, immediately use the product, or dispose of it. If the information is only sent to the maintenance company, the corrective action cannot be taken straight away, and food safety and hygiene cannot be guaranteed in time.

- IoT sensors must be able to penetrate thick walls and stainless materials to avoid weakening the connections between devices. Food safety is not guaranteed when the information about out-of-range temperatures does not reach the relevant people in time.A sense of urgency is important when it comes to applying food safety corrective actions and additional maintenance.

- Smart fridges and freezers rely on the internet to deliver the data to your main database. In the absence of a strong connection, monitoring can be delayed and quality assurance inspectors may miss any non-compliance.

- IoT device sensors are very sensitive. They can also be easily damaged when mishandled. Damages would mean that faulty reading can be recorded. In such events, a manual thermometer must be ready to double-check temperature readings.

How can I help my team remember to fill food and refrigerator temperature logs?

Filling all of your temperature logs on time can be challenging because of the sheets of paper involved, devices in use, and team members being busy with customers or other tasks

That's why it's important for managers to find a food safety program that will help instead of buden your team with additional obligations.

At FoodDocs, we offer the best digital food safety software solution for monitoring temperature readings. Our system is capable of automatically generating digital and smart temperature monitoring logs for your food safety team.

These digital monitoring forms are equipped with an auto-fill feature which allows our system to pre-fill the forms based on previously logged everyday temperature data. With such a feature, you can help your team save time and focus on the verification of the tasks.

On top of this, our system can even help remind your team when to read current temperature levels. Using our mobile application, our system will send smart notifications to your food employees and remind them of the task. Because we understand how different establishments have varying protocols, you can set the time of whenever a temperature reading is needed and we'll remind your team.

In addition to these features, our system is also compatible with the most advanced smart fridges equipped with IoT sensors. This means that you can integrate our system with your smart sensors for a seamless transfer of temperature readings from your freezer and refrigerators.

This feature can also be used to show information on your food products equipped with barcodes.

How to set up all your food safety monitoring logs in 15 minutes

Here are more food safety solutions that our digital FSMS offers for your team:

- Save your employees' time. App notifications and pre-filled tasks about upcoming monitoring save time on monitoring, audits, reviews, reporting, logistics, training, etc. Our mobile app notifies you of your important daily tasks and when critical limits are breached. Access to monitoring information even becomes easier and more efficient because everything is stored in a single smart software that can help you organize your data.

- Spend less time on supervision. Our digital software enables a real-time overview of food hygiene completion in the team and what units or departments have issues through a food safety dashboard. This feature can help you save at least 20% of your time from supervising every operation in your food business. You can also use this feature to identify areas that need more improvement and have an overview of food hygiene at any time.

- Improve your employees' food safety awareness and food quality with a digital solution. Notifications about scheduled tasks enable quicker response and damage control. Our digital solution also keeps everyone updated with the latest revisions on food regulations and laws.

With the help of our digital FSMS, you can maintain food safety compliance effortlessly. Try FoodDocs today with a 14-day free trial.