Recalled products require critical attention and proper handling to contain potential food safety issues.

Food recalls are bad news for food businesses and public health authorities alike. They require undivided attention from the food business involved to become successful.

Food business operators must oversee every step taken to ensure that no further problems arise and that the affected customers are compensated and attended to.

In this post, we will discuss how to properly handle recalled products to maintain food safety.

Key points covered:

- A food recall is a voluntary or mandated action performed by a distributor or manufacturer to pull out products that may have caused food safety issues from the market.

- Recalled products refer to food items that are proven to carry significant health hazards when consumed.

- Identified recalled products must be separated from safe food products until a final decision is made on whether they will be disposed of or reprocessed.

- Restaurant managers are in charge during a food recall.

- FoodDocs' smart Food Safety Management System features an all-in-one traceability system that can be used to collect critical information for a food recall.

- Our system also features customizable monitoring tasks that can be attached to the traceability system to further enhance legal compliance.

What is a food recall?

A food recall is an action taken by a food manufacturer, distributor, or regulatory agency to remove those products from the market that may pose adverse health consequences to public health. It can be voluntary or mandated by government agencies.

Common reasons behind a food recall include contamination, consumer issues, cases of foodborne illness, mislabeling, undeclared ingredients, or the discovery of potentially undeclared allergens in the product.

What are recalled products?

Recalled products are items that have been identified as potentially harmful or in violation of safety standards. They are removed from distribution and sale to prevent further consumption by the public.

These products may have foreign objects that could cause injury or have the potential presence of bacteria that could cause foodborne illness.

Food businesses must understand how to properly handle recalled products, as they can potentially have harmful elements. This is why they should be separated from safe food and handled with care.

What is the best way to handle recalled food items?

In case of a food recall, recalled products should be separated from the food being served until they’re cleared by the relevant authorities.

This is key to preventing further food safety issues for any type of recall.

If you are a business owner dealing with a recalled food item, handling the situation swiftly and responsibly is crucial to protect your customers and uphold your business's reputation. You want to follow the following steps for handling recalled food items:

- Stop distribution of products.

- Isolate the remaining inventory of food products.

- Communicate with suppliers.

- Inform parties involved about the recall.

- Post recall notices or consumer alerts.

- Cooperate with regulatory agencies.

- Implement corrective actions.

- Communicate with all affected parties.

- Review and revise procedures.

- Rebuild trust with consumers.

You can also use FoodDocs' two-in-one traceability system to handle recalls professionally. It allows you to easily identify and collect information about the affected products and issue detailed recall notices or public health alerts.

Our traceability system also features an advanced search option that allows you to access the information needed for a food recall quickly. This streamlines the communication between your business and regulatory agencies to minimize further food safety issues.

When an operation is notified of a food item recall, what is the best action for the person in charge to take?

When an operation is notified of a food item recall by a ffood safety agency, the person in charge (PIC), who's often one managing recalls, should first verify the accuracy and relevance of the recall information, ensuring it applies to the products found in their inventory.

The PIC in a food company must maintain detailed records, cooperate with regulatory authorities, follow health codes, and remove affected products from shelves. They are also responsible for implementing rules to avoid cross-contaminating food products and releasing consumer guides for those affected by the food product recall. In most cases, the PIC will also be required to compensate for any medical bills and health care provider fees resulting from the contaminated product.

In addition, the PIC must perform a comprehensive review of food safety procedures, staff training, and ongoing monitoring and evaluation to prevent future incidents.

What must a manager do with a recalled food item in the operation?

When there's a recalled food item in the operation, a manager must:

- Locate and list all products subject to recall.

- Extract these products from inventory and secure them in a designated area.

- Ensure these items are stored away from food, utensils, equipment, linens, and disposable items.

- Clearly mark the items to avoid their reintroduction into inventory.

- Communicate to all staff members that these products are not to be used.

- Consult the vendor’s recall notice or notification to determine how to properly handle or discard the recalled products.

What is a restaurant manager's responsibility when notified about a food recall?

When a restaurant manager is notified of a food safety recall, their primary responsibilities involve fast verification of the recall's applicability and identification and isolation of the affected products within the inventory.

They are also responsible for communicating with health agencies in controlling the recall process and releasing alerts about the health hazard situation.

Managers are also responsible for minimizing any health hazards, such as potential food poisoning or allergic reactions that their product may have caused. They must stay aware of the reasons for consumer recalls and communicate the recall internally to the recall response team, and externally to customers.

Proper procedures outlined in the recall notice, such as removal or return of products and compliance with health authorities, must also be efficiently conducted.

In addition, the manager must ensure that all food safety records are available and accessible for verification.

Once the recall is over, it is part of the food manager's responsibility to conduct a post-assessment of the recall. This includes verification of the precautionary measures in place to prevent unsafe products from being released.

Managers can use FoodDocs' traceability system to manage a food recall efficiently. It features advanced search options that you can use to access information about the recalled product instantly. With just a few clicks, you can get a detailed summary of the product batch in question and print it for the food safety inspector.

Why is it important to handle recalled foods properly?

Handling recalled foods with precision and care is critical to responsible food management in the industry. It is essential for safeguarding consumer health, maintaining legal compliance, and preserving the reputation of food establishments.

Let’s take a deeper look:

- Consumer safety. One primary concern is the protection of consumer health. Recalled foods may pose health hazards due to foreign objects or the presence of major allergens. Proper handling ensures that consumers are not exposed to potentially harmful products.

- Legal compliance. Proper handling of recalled foods helps the food establishment comply with local, national, and international regulations, avoiding potential legal consequences and liabilities.

- Reputation management. The way a business responds to a food recall can significantly impact its reputation. Handling recalls transparently, efficiently, and responsibly demonstrates a commitment to customer safety and can mitigate reputational damage.

- Risk reduction. Proper handling ensures that recalled products are promptly removed from the market, preventing further distribution and consumption. This containment is essential to minimize the potential impact of the recall and maintain consumer confidence.

- Cost reduction. Properly handling recalls can reduce the risk of lawsuits and regulatory fines.

Handling recalled foods carefully is critical for any food business. It's not just about following rules — it's a basic duty to keep customers safe and retain their trust. Doing it right also helps the business keep running smoothly, lowers the risk of legal action, and demonstrates a commitment to continuous improvement.

How can FoodDocs help in handling food recalls?

Your team must act quickly and efficiently during a food recall to contain damage. You can do this only if you already have a comprehensive recordkeeping system. This is where FoodDocs' smart Food Safety Management System with a traceability feature comes in. It offers:

- An all-in-one Traceability System for more efficient handling of recalled foods

- Customizable monitoring tasks that will help support traceability records

All-in-one Traceability System for more efficient handling of recalled foods

During a food recall, worsening the damage is the last thing that you want to do. Using our all-in-one traceability system, you can control the issued recall by quickly accessing information about the product in question.

You can also store your ingredient and product information in our system and access them using our advanced search options. In the event of a food recall, simply enter the production batch number of the product in question and our system will present to you all related information in one file. This includes:

- Product name

- Ingredients

- Batch number/production dates

- Target amount

- Expiry date

Swift access to information will allow you to present it to the food inspector and quickly identify all affected products.

Two-in-one Traceability System from FoodDocs software

Customizable monitoring tasks that will help support traceability records

You can also use monitoring tasks to support traceability further and prepare related information for a smoother food recall.

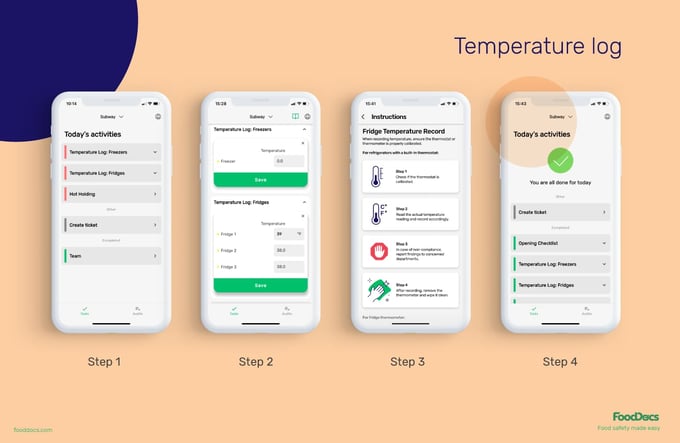

Our food safety monitoring software can automatically generate customizable monitoring tasks that can be used to record critical information about your operations. Examples of logs include:

- Receiving chilled goods log

- Temperature log

- Freezer log

Customizable monitoring tasks from FoodDocs software

You can demonstrate your compliance efforts by presenting detailed records to the food safety inspector. In addition, you can use these monitoring tasks to identify the root cause of the food recall.

Simply attach the monitoring task to a particular product batch in our traceability system and keep all information organized.

While it is critical to separate products for a food recall, it is also important for a food business to be able to present supporting documents that will help in identifying the root cause of the problem.

This simple yet vital practice is a key step in ensuring consumer safety, adhering to regulatory requirements, and safeguarding the reputation of businesses. By diligently isolating and clearly marking recalled items, establishments demonstrate their commitment to responsible operations and contribute to the overall integrity of the supply chain.

Learn more about how our system can help you handle food recalls by booking a demo with our experts.