HOW TO USE A FOOD THERMOMETER?

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

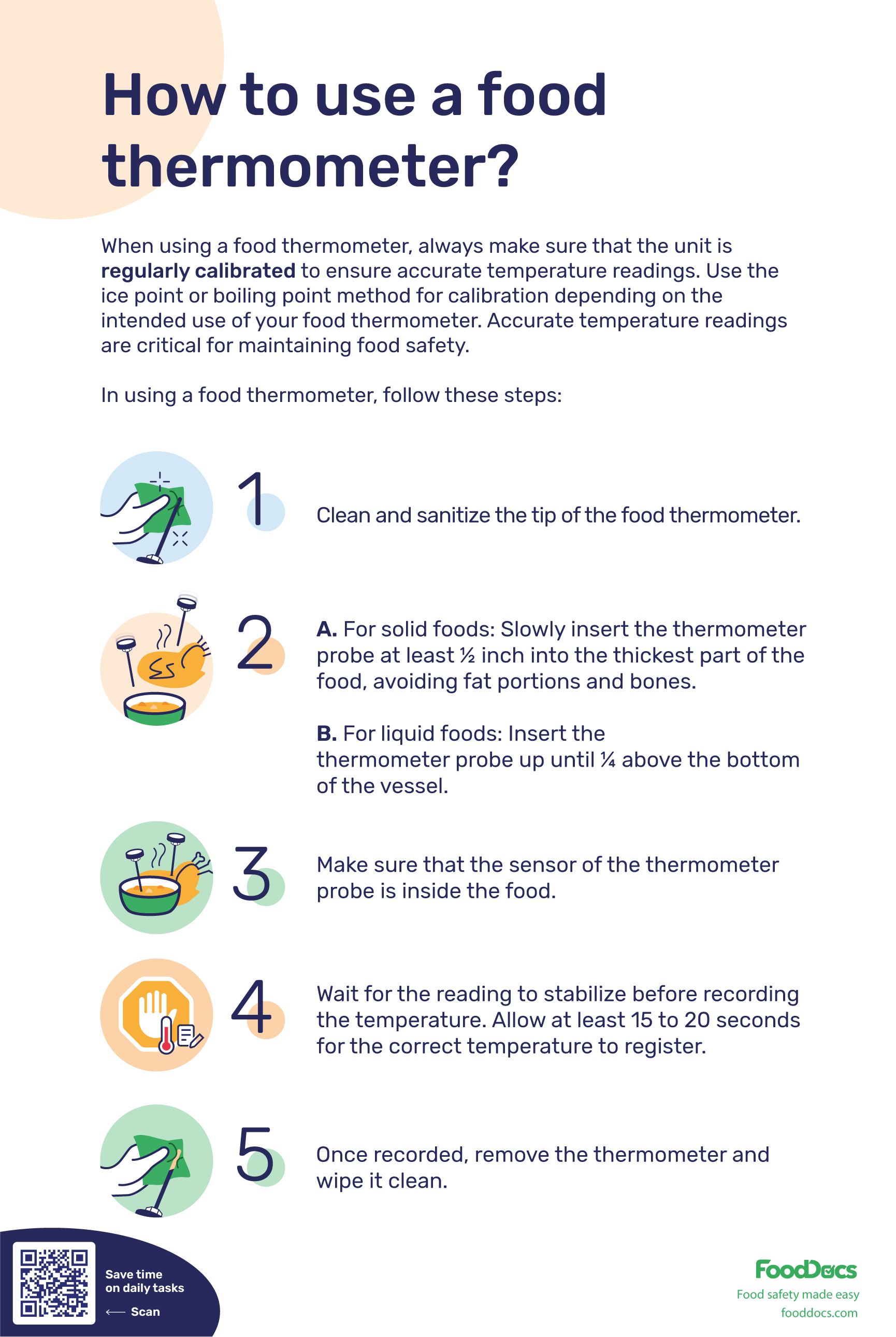

How to use a food thermometer

Temperature measurement is one of the most basic operations in a food establishment. Food safety measures against foodborne bacteria and outbreaks of food poisoning are highly dependent on temperature control. Whether it is for storage or cooking, temperature control will affect the effectiveness of your operation. As such, food service operators must always be trained on how to use a food thermometer regardless of which types of food thermometers you have in your restaurant.

Thermometers, especially the analog types, are commonly composed of a probe or the metal stem and a read-out dial. The probe component was designed to allow it to be conveniently inserted into solid and liquid foods. Almost all food thermometers conventionally work using the same principle and commonly vary depending on features such as display of reading and suitability of the material for extra-high temperatures such as direct exposure from a heat source. Food safety agencies classify using a food thermometer as an essential operation for determining the safety and doneness of foods.

Find out how to properly use a food thermometer with this article, and learn about our digital solution for maintaining food safety.

What is a food thermometer guide?

A food thermometer guide is a visual tool depicting the steps on how to use a food thermometer. This guide can be used by food handlers as a reference when measuring food temperature. Additionally, it can also be used to orient new food workers to ensure that they know how to use your available thermometer.

The proper use of a food thermometer is crucial to be able to acquire an accurate reading. For example, if the dial-type thermometer is not properly inserted up to the sensor of the probe, the thermometer reading may be too low or inaccurate in general. Additionally, food handlers must know how to measure the temperature of hot foods or cold foods being held for storage to avoid the temperature danger zone. In case of large batches of food, an appliance thermometer can be used to prevent unnecessary bacterial growth.

When checking a food temperature, a food handler should monitor the thermometer until the reading becomes stable. The stability of the reading may vary depending on the type of food thermometer. Digital thermometers usually take at least 30 seconds to stabilize, whereas manual food thermometers only require 15 to 20 seconds. Stability, in this case, means that the reading is either not changing or there is only a very small difference in the fluctuation.

Who needs a food thermometer guide?

Every food business including restaurants, retail food stores, food trucks, cafeteria, and even warehouses need a food thermometer guide. All food businesses have an operation that is related to controlling temperature. It can be for food storage, cooking, delivery, or preparation or raw and ready-to-eat foods. All food handlers must be well oriented on the simple steps of how to record the safe temperature for foods.

What is the core temperature of food?

The core temperature of food refers to the temperature of a product at its thickest portion, or the thermal center when subjected to heating. The center of a food product is the location where heat from cooking will take the longest to reach. As the temperature of the food increases in the center portion, the whole product becomes subjected to high and equal temperatures.

The target core temperature of foods is usually based on the associated foodborne pathogen to food. This temperature range is defined to be able to deactivate the pathogen and make it safe for consumption. The core temperature of foods and cooking time are two important factors in any cooking process.

The core range of temperature also serves as a target factor or indicator for cooking any piece of meat to a particular doneness range. Raw meat such as different cuts of beef or even ground meat is assigned a range of core temperatures to target different levels of doneness. The final internal temperature of beef or other foods will determine its eating characteristics and safety.

Why is measuring food cooking temperature important?

The final temperature of a food being cooked can be translated to its level of safety. Each type of food requires a certain target correct temperature to ensure that the pre-existing pathogenic bacteria are killed. Food handlers need a way to determine whether the cooking process was adequate enough to reach the ideal temperature to stop the growth of bacteria. Accurate cooking temperature is also key to avoiding contamination from bacteria.

This objective can be achieved using a properly calibrated, conventional food thermometer. When foods are undercooked due to the wrong temperature, the risk of causing foodborne illness significantly increases. Customers who have weak immune systems are particularly prone to suffering from food poisoning. This group of consumers includes pregnant women, childer under the age of five, the elderly, and those with immune system deficiencies.

In addition to food safety reasons, accurate temperature readings using ensure the quality of food. As food cooks, the quality of the food item changes. The resulting characteristics depend on the extensiveness of the cooking.

How often should you measure food's internal temperature?

For cooking, you would only need to measure the internal temperature of your food once or until the target temperature has been reached. Some types of thermometers such as an oven-safe thermometer are used by inserting the unit into the food while it is being cooked, so you could monitor the internal temperature constantly. Oven-proof thermometers are often made to withstand extreme heat conditions.

Measuring temperature for safety only takes around 15 to 30 seconds depending on the thickness of your food and the type of thermometer you are using. Thinner foods, including liquids, naturally give out faster temperature readings as the heat travels faster. Waiting for the temperature reading to stabilize is a crucial step to avoid causing any gastrointestinal illness.

Target internal food temperatures must always be measured correctly as it is one of the most important aspects of food safety. Inaccurate measurement of temperature may allow harmful bacteria in food to grow and cause significant problems.

What equipment do you need to measure temperature?

The most suitable tool for measuring safe cooking temperature in a restaurant or any food establishment setup is a common kitchen thermometer. Regardless of the cooking method or cooking utensil used to prepare the food, cooking thermometers would be the best tool for measuring temperature.

A thermometer is an essential kitchen tool that can be a standalone unit or equipped as a basic kitchen appliance. With this, food thermometer accuracy must also be assured. It is the most practical tool to measure the temperature of even the thinnest foods to keep customers safe from foodborne illnesses.

Food thermometers come in different shapes and sizes. Some of the most common types of thermometer include:

- Bimetal food thermometer

- Oven thermometer

- Digital thermometer

- Infrared thermometer

- Liquid-filled thermometers with glass stems

A properly calibrated thermometer would be able to accurately tell you whether the food being prepared needs additional cooking or if it is already safe to eat. It is essential to regularly calibrate your thermometers for exact temperature readings and to avoid inaccurate readings. Use the ice water method and boiling point methods for this operation.

To help you monitor your food safety progress, use appropriate monitoring logs. Find out which food safety document is the best fit for your food safety operations from our HACCP plan template hub. Use our cooking temperature logs for monitoring your food cooking temperature or our thermometer calibration forms for recording your calibration readings. The best thing about these food safety documents is that they are all free! You can download and distribute them to your team for your everyday operations.

To help you understand how to properly use a thermometer, here are some frequently asked questions about this topic:

What is the proper way to use a food thermometer?

A food thermometer must be always cleaned and properly calibrated before use. Your thermometer will come in contact with food which can cause cross-contamination.

Follow these steps for reading the temperature of foods using a thermometer:

1. Clean and sanitize the tip of the kitchen thermometer.

2. For solid foods: Slowly insert the thermometer probe at least ½ inch deep into the thickest part of the food, avoiding fat portions and bones.

For liquid foods: Insert the thermometer probe up until ¼ above the bottom of the vessel.

3. Make sure that the sensor of the thermometer probe is inside the food.

4. Wait for the reading to stabilize before recording the temperature. Allow at least 15 to 20 seconds for the correct temperature to register.

5. Once recorded, remove the thermometer and wipe it clean.

What are the three rules for using a food thermometer?

When using a food thermometer, consider the following rules:

- Calibrate your thermometer properly;

- Clean the thermometer before and after use to avoid cross-contamination;

- Insert the food thermometer into the thickest part of the food to acquire the core temperature.

How do you use a digital food thermometer?

Unlike a regular bimetallic or dial thermometer, a digital instant-read thermometer features a digital read-out or digital display. After inserting the digital thermometer at least 1/2 inches deep into the food, it will automatically give you a temperature reading. Allow the reading to stabilize for 20 to 30 seconds to avoid inaccurate temperature readings.

How can you help my team keep in mind measuring meat cooking temperature?

There are more ways to help your employees measure cooking temperature than just providing them with a helpful poster. More pressing matters such as timely execution of food safety operations and more accurate recordkeeping require more advanced solutions. With the constantly changing scenario in the food industry, your team needs to keep up by getting a smarter solution to solve everyday problems.

Food safety operations undeniably take too much time to perform but are requirements if you want to keep operating and serving customers without causing foodborne illnesses. Achieving food safety compliance also needs a lot of admin work such as filing and keeping all documents organized correctly. With all the many different food safety operations needed to be performed in a day, the risk of forgetting a food safety task increases for food handlers.

In addition to our "How to Use a Food Thermometer" poster, we also offer a smarter digital solution for your food safety operations. At FoodDocs, we have developed a digital solution for your food safety plans to help food businesses maintain compliance and protect customers at the same time.

To help you make food safety operations more efficient and effective, we have included some of the most common monitoring operations in our digital solution. When you avail of our services, you can get the following benefits:

-

Save your employees' time. Our digital monitoring forms are equipped with an auto-fill feature to help your team save time from repetitive filling. The information that we use is based on your previously logged data.

-

Get detailed instructions. Not only do we generate monitoring forms, but we also help food employees learn how to perform food safety tasks. With our monitoring logs, we have included a set of detailed step-by-step instructions for a particular task that is important in every food business. New food employees can use this feature to facilitate the onboarding process.

-

Get smart reminders. To help every food handler remember a task that needs to be done, our system can send intuitive notifications through our mobile application. This feature can also be used to remind food handlers of any perishable food that is about to expire. Reduce waste and remember all food safety tasks with our digital solution.

We have also developed digital solutions to help food business managers make managing more efficient and effective:

- Manage your food safety operations remotely. Use our real-time food safety dashboard to get an overview of your everyday food safety operations and save at least 20% of your time from managing your team.

- Get cloud-based storage for your team. Store all your digital documents in your dedicated storage space where you can organize and access everything easily.

What is even greater with our digital solution is that our whole digitalization process would only need an average of 15 minutes. Our system can automatically generate helpful monitoring logs that you can use to record accurate temperature readings.

Using artificial intelligence, our digital FSMS can automatically generate all the important food safety documents for you through a comprehensive digital Food Safety Management System.

Our digital solutions were specifically made to make food safety compliance much easier for food businesses. For operations like temperature reading which is done multiple times in a day, our solution can help food handlers retain consistency and accuracy throughout their daily operations.

You can experience all of our digital solution features by signing up for our free, 14-day trial.