Kitchen Prep List Template: How to Create One for Maximum Efficiency

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

Behind every smooth restaurant service is a morning of diligent prep work. Kitchen prep lists — those trusty production sheets that outline every chopping, mixing, and pre-cooking task — are the unsung heroes of an efficient kitchen.

Picture the quiet hours before the restaurant opening: the prep cooks are washing produce, dicing vegetables, simmering sauces, and portioning proteins, all guided by a clear prep list. Without this plan, even the best team can end up scrambling mid-service.

In this guide, we’ll break down what kitchen prep lists are, why they’re essential, how to create and use them effectively, and how digital tools can take your prep process to the next level.

Whether you’re a seasoned kitchen manager or a prep cook just starting out, these insights will help ensure no task is left undone and no ingredient runs out when the dinner rush hits.

Top 6 Free Restaurant Management and Safety Resources

What is a kitchen prep list?

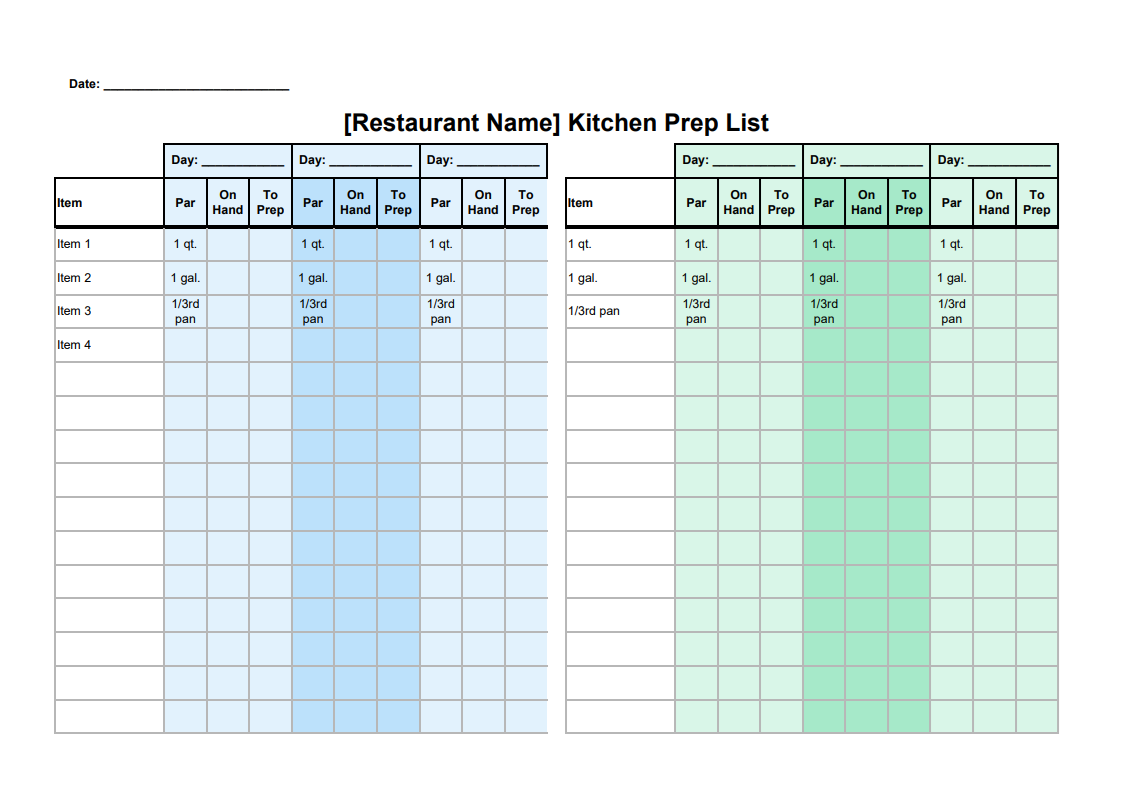

A kitchen prep list (also called a restaurant prep list, prep sheet, or par sheet) is a printed or digital guide detailing all the food prep tasks that must be completed for a given day or shift. It’s essentially the game plan for your kitchen’s mise en place.

The prep list outlines which ingredients or menu components to prepare, and in what quantities, to meet the expected demand of service. Without a prep list, your cooks would have no clear idea how many portions to prep.

For example, how many heads of broccoli to blanch or how much steak to cut for the night. The result would be guesswork at best and chaos at worst.

Why is a kitchen prep list so critical?

For one, it ensures consistency and prevents costly mistakes. Providing exact targets (often called par levels) for each item will prevent you from over-prepping your prep list and creating unnecessary food waste.

It’ll also help you avoid under-prepping, which can lead to 86’ing popular dishes mid-service. It’s the tool that helps your team prep the right ingredients in the right quantities every time. In short, a prep list is the safety net that catches oversights before they happen.

It keeps the kitchen running like a well-oiled machine: you never miss a sale because you ran out of something, and you don’t end the night throwing away tubs of unused prep.

The prep sheet is what the kitchen staff uses to make sure they're prepping the right ingredients in the right amounts.

How can technology streamline kitchen prep?

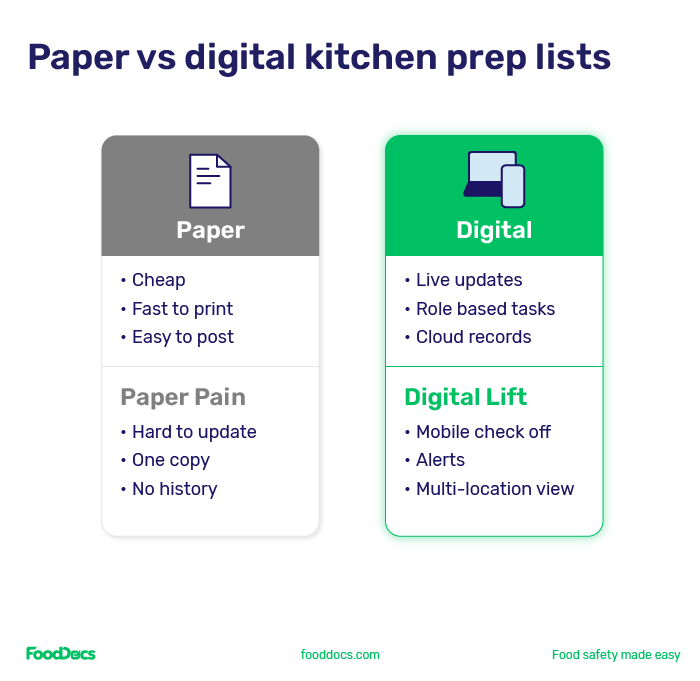

Traditionally, kitchen prep lists are printed on paper or scribbled on a whiteboard. While a paper checklist does the job, it has drawbacks. They:

- Get lost or messy

- Are not easily updated in real-time

- Sit in the kitchen where a manager off-site can’t see it

That’s where digital solutions can improve operations and processes when it comes to kitchen prep lists and restaurant management and food safety monitoring as a whole. They make life easier for both kitchen staff and managers.

Consider the benefits of taking your prep list digital: a digital checklist can be accessed on a tablet or phone, meaning it’s available to everyone on the team in real time, and managers can see updates instantly.

Rather than a single paper hung on a clipboard, each cook could view their prep tasks on a mobile app and check them off as they go. See how it works with FoodDocs!

Many restaurant operators are now using food safety and kitchen management software that allows all daily checklists (from opening duties to prep tasks) to be completed via mobile device.

Key takeaways

-

A kitchen prep list is your daily plan that keeps service steady and stops waste.

-

Par math is simple: par minus on hand equals to prep.

-

Use a weekly list for base batches and feed a daily list from it so today’s prep matches demand.

-

Set pars from sales and covers, then use a small waste log to raise or drop them when patterns repeat.

-

Label every item with date, time, and initials, and use clear shelf life rules to keep food safe.

-

Add allergen flags and plan the order of prep to lower cross-contact risk.

-

Group tasks by station and run a five-minute huddle and end-of-shift handoff so nothing is missed.

-

Hold cold at 41°F or below, hold hot at 135°F or above, and cool through the danger zone on time.

-

Block prep time on the schedule by station and assign a name to every line on the list.

-

Going digital with FoodDocs' restaurant food safety software lets you scale recipes with prep instructions and an automated allergen matrix.

What are the main benefits of using a kitchen prep list?

Using a daily prep list brings several concrete benefits to any commercial kitchen:

- Reduces food waste: Accurate par levels on the prep sheet prevent the team from over-prepping ingredients that won’t be used, thus cutting down on food waste. Prepping only what’s needed means less excess wilting in the walk-in.

- Helps you meet demand: No chef wants to 86 a best-selling menu item at 7 PM. Prep lists help ensure you meet customer demand by having sufficient portions of each component ready, so you never miss out on a sale due to a lack of prep.

- Speeds up service and reduces wait times: When the right tasks are completed before the rush, line cooks can assemble dishes quickly. Proper prep reduces guest wait times because the ingredients are cleaned, cut, and measured in advance.

- Keeps the kitchen organized: An organized prep sheet keeps the prep team focused and on-task. Everyone knows what needs to be done and who’s doing it, which speeds up prep work and ensures nothing is overlooked. This organization early in the day translates to a more streamlined, less chaotic operation during service.

Successful kitchen prep starts with a well-crafted prep list. It’s a simple tool that has a powerful impact on food cost control, food quality, and service efficiency.

What’s the anatomy of a kitchen prep sheet?

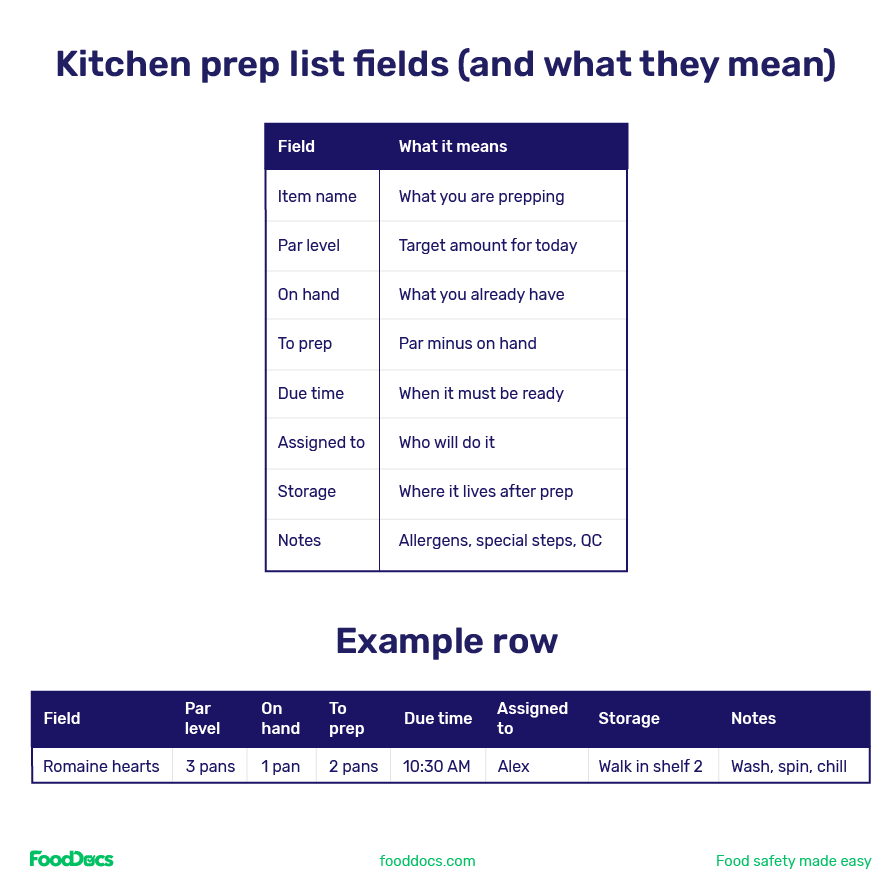

So, what does a kitchen prep list actually look like? Most prep sheets use an easy-to-read grid or table format. While specific layouts can vary, a typical prep list includes the following five columns or elements:

- Menu item / ingredient: The specific food item that needs prepping (e.g. “Romaine Lettuce,” “Tomato Soup,” “Chicken Breast, diced”).

- Par level: The target quantity needed for that item for the day or shift. The par is usually based on expected sales or covers. For example, if you usually sell 25 orders of a dish that uses rice, the par for cooked rice might be enough for 25 portions. Par levels are often given in kitchen-friendly units (e.g. “3 pans of salad greens” or “5 lbs of diced onions”).

- Quantity on hand (QOH): How much of that item is already prepped and available from previous shifts or earlier prep. Before doing new prep, the team checks what’s left from yesterday or from the morning deliveries.

- Quantity to prep: The amount that needs to be prepped today to reach the par level. This is usually calculated as Par minus Quantity on Hand. If the par is 3 pans of lettuce and you already have 1 pan left from yesterday, for example, you need to prep 2 more pans.

- Actual prepped / total: After prepping, the sheet will record how much was actually prepped and the new total on hand. Often this is just a confirmation that QOH + prepped = Par (or the required total). There may also be a space for the prep cook’s initials or signature once the task is done.

One crucial element on prep lists is the concept of Par Level. A par level is the optimal amount of each ingredient or prep item that should be on hand to meet the anticipated demand for a given service.

Setting par levels is a balancing act: too high and you waste food, too low and you might kick yourself for running out and losing sales. Par levels are determined by historical sales data, portion sizes, and sometimes gut feeling/experience.

For example, if on Fridays you typically go through 25 orders of fish and chips, you’d set a par of the ingredients (battered fish, portioned fries, tartar sauce, etc.) sufficient for at least 25 orders. If you consistently find you’re short or have excess, the par level needs adjustment. We’ll dig into how to fine-tune par levels shortly.

How should you handle allergens and cross-contact in the kitchen prep list?

Add allergen info to the template so cooks do not guess and plan the order of prep to lower risk. Start by adding these fields:

- Allergen flags

- Clean zone needed (Yes or No)

- Tools needed or color code

Here are some simple rules to follow:

- Prep allergen-free items first

- Use color-coded cutting boards and knives

- Wash, rinse, and sanitize

between tasks - Label allergen items clearly with name and date

- Store allergens under ready-to-eat items to avoid drips

Download your free food allergen posters

What are examples of daily and weekly prep lists?

Daily kitchen prep lists cover what you need for today. Weekly kitchen prep lists cover your base work for the week.

Daily prep list focus

- Salad greens washed and spun

- Cut vegetables

- Cooked grains and rice

- Backup sauces and dressings

- Portioned proteins

- Garnishes and toppings

Weekly prep list focus

- Stocks and broths

- Demi and mother sauces

- Marinades and brines

- Pickles and ferments

- Spice blends and rubs

- Doughs and batters for freezing

How to use both types of prep lists

- Build the weekly list from your core menu

- Feed the daily list from those base items

- Review both on Mondays and Fridays (and adjust)

What are the 10 steps to using a kitchen prep list?

Having a prep list is only half the battle. Your team also needs to use it correctly. Using a kitchen prep list becomes second nature once you get the hang of a few basic steps.

Here’s a straightforward procedure to follow each day when executing your prep, adapted from the 10 most common best practices:

- Review the menu and stations: First, make sure you have the right prep sheet for the upcoming service (e.g., lunch vs. dinner, or specific stations like salad prep, grill, etc.). Some kitchens use separate prep lists per station to stay organized.

- Locate each item on the list: Go through the prep list one item at a time. For each ingredient or component (say, marinara sauce or diced onions), identify it in the first column of the sheet. The list may be grouped by station or category to make this easier.

- Note the par level: For the item, check the par level listed. This is your target quantity for that item for today. Keep this number in mind because it’s what you need to end up with after prepping.

- Check quantity on hand: Before you start chopping or cooking, see what’s already on hand from previous prep or deliveries. Look in the fridges, storage, or yesterday’s labeled containers. Is there leftover soup from yesterday? Do you have any diced onions remaining from the morning delivery? Count or measure what you have and note it.

- Verify quality of leftovers: If you do find pre-prepped items from before, ensure they’re still good to use. Discard anything that’s past its prime, including wilted greens, sauce that’s been held too long, etc. Only wholesome, safe, and high-quality leftovers should count toward today’s prep.

- Calculate what to prep: Now do the simple math: Par Level - On Hand = Amount to Prep. For example, if the par is 3 pans of salad greens and you have 1 pan left, you need to prep 2 more pans of fresh greens. This calculation ensures you top up to the required par without overshooting.

- Get prepping: Perform the prep work for that item. This could be chopping, cooking, mixing, or other related tasks. Focus on one item at a time so you can measure accurately and not miss anything.

- Record the results: Once the task is complete, record on the sheet how much you prepped and, if required, sign or initial that line. For instance, if you were to prep those 2 pans of salad greens, mark “2 pans prepped” (some sheets have a column for “Qty Prepped”) and add your initials to show accountability.

- Label everything: Immediately label the prepped food item’s container with the date, time, and your name or initials (if not already portioned in dated containers). This is Food Safety 101: labels ensure first-in, first-out usage and traceability. It also helps the next shift or your chef quickly identify what was prepped and when.

- Store properly and move on: Place the prepped item in its proper food storage location. This could be in the walk-in cooler, the line’s reach-in, or the dry storage. Make sure it’s covered and stored at the right temperature. Then, go back to the list and proceed to the next item, repeating the process.

Following these steps, item by item, ensures that by the time you’re done, every required prep task is completed and documented. A good prep list should have everything checked off before service starts. Many kitchen teams have one person coordinate or double-check the prep list (often a sous chef or kitchen manager), making sure nothing is skipped.

When every item’s prepped and accounted for, you and your team can head into service confident that you won’t be caught off guard.

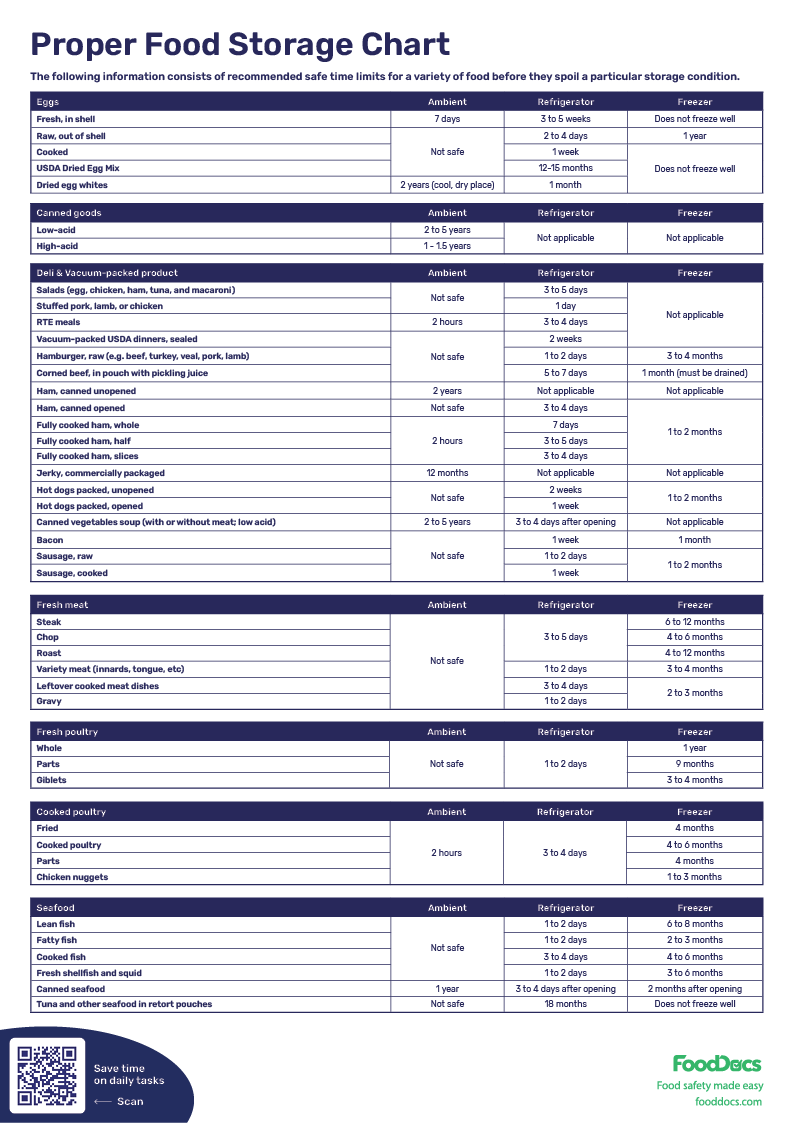

Get your free proper food storage chart

What are some examples of station-based prep?

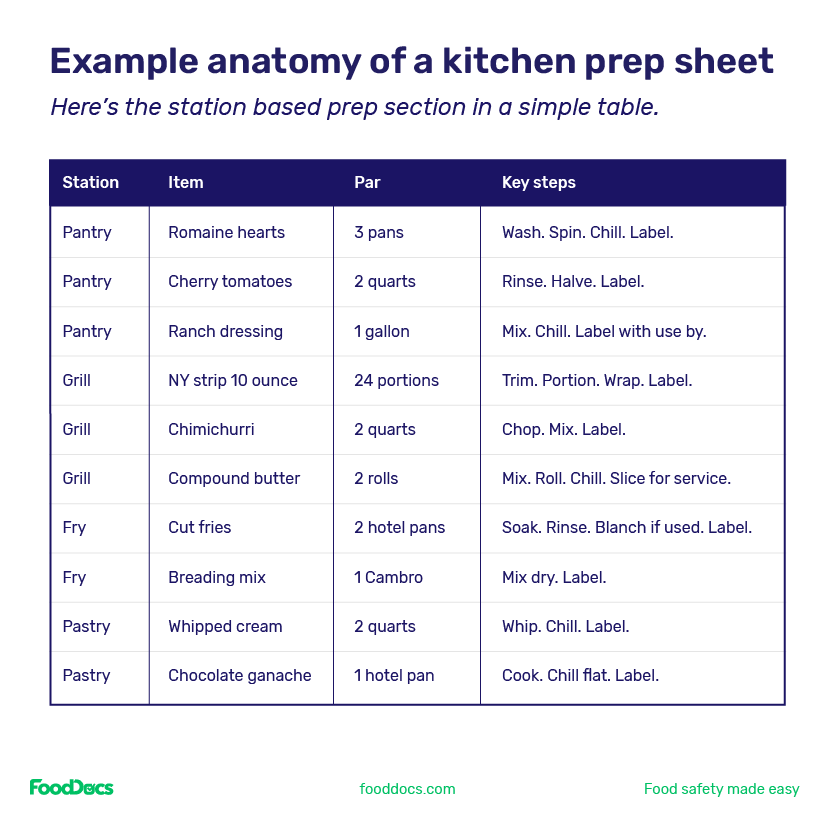

Here’s the station based prep section in a simple table.

|

Station |

Item |

Par |

Key steps |

|

Pantry |

Romaine hearts |

3 pans |

Wash. Spin. Chill. Label. |

|

Pantry |

Cherry tomatoes |

2 quarts |

Rinse. Halve. Label. |

|

Pantry |

Ranch dressing |

1 gallon |

Mix. Chill. Label with use by. |

|

Grill |

NY strip 10 ounce |

24 portions |

Trim. Portion. Wrap. Label. |

|

Grill |

Chimichurri |

2 quarts |

Chop. Mix. Label. |

|

Grill |

Compound butter |

2 rolls |

Mix. Roll. Chill. Slice for service. |

|

Fry |

Cut fries |

2 hotel pans |

Soak. Rinse. Blanch if used. Label. |

|

Fry |

Breading mix |

1 Cambro |

Mix dry. Label. |

|

Pastry |

Whipped cream |

2 quarts |

Whip. Chill. Label. |

|

Pastry |

Chocolate ganache |

1 hotel pan |

Cook. Chill flat. Label. |

What can you do to ensure proper labeling, shelf life, and food storage during prep?

Clear labels and smart storage keep food safe and cut waste.

Consider adding these fields:

- Date and time prepped

- Use by date

- Storage location and temperature

- Prep cook initials

Common shelf life guides include:

- Cut leafy greens, 2-day shelf life stored cold

- Cooked rice, 2-day shelf life, stored cold

- Cooked proteins, 3-day shelf life stored cold

- Egg- or dairy-based sauces, 3-day shelf life stored cold

- Oil-based dressings, 5 to 7-day shelf life stored cold

Of course, you’ll need to set your limits according to your chef and local code.

As a best practice, follow these food storage tips:

- Use shallow pans for fast cooling

- Keep lids loose until Items are cold

- Place newer batches behind older batches

- Post a small FIFO sign in each cooler

What’s the key to creating an effective kitchen prep list?

If you’re in charge of making the food prep list itself (rather than just using one), this section is for you. Crafting a prep list tailored to your kitchen involves two main components: identifying the prep tasks and setting accurate par levels. Let’s break down each part.

1. List all prep tasks (analyze your menu)

Start by reviewing your menu in detail and listing out all the prep tasks that can or should be done ahead of service. Essentially, you’re doing a mini analysis of each menu item to figure out its make-ahead components versus what must be cooked à la minute. For every dish (i.e., appetizers, mains, sides, desserts, as well as garnishes and sauces), ask: What steps can be done in advance?

For example, consider a classic hot wings appetizer. If you break down the preparation of buffalo wings, you might get two lists like this:

- Prep work (do before service): Thaw frozen wings; cut and portion wings into servings (e.g. 10-piece portions); pre-make all the wing sauces and keep them warmed; wash and cut celery sticks; prepare blue cheese and ranch dipping sauces.

- Cooked to order (at time of service): When an order comes in, fry the wings; toss them in the pre-made wing sauce; plate them up hot with the pre-cut celery and a ramekin of dip.

And don’t forget non-menu-specific prep tasks like daily butchery (e.g., trimming steaks) or backing up pantry items like refilling salad dressings into line bottles. Compile a master list of all these prep tasks.

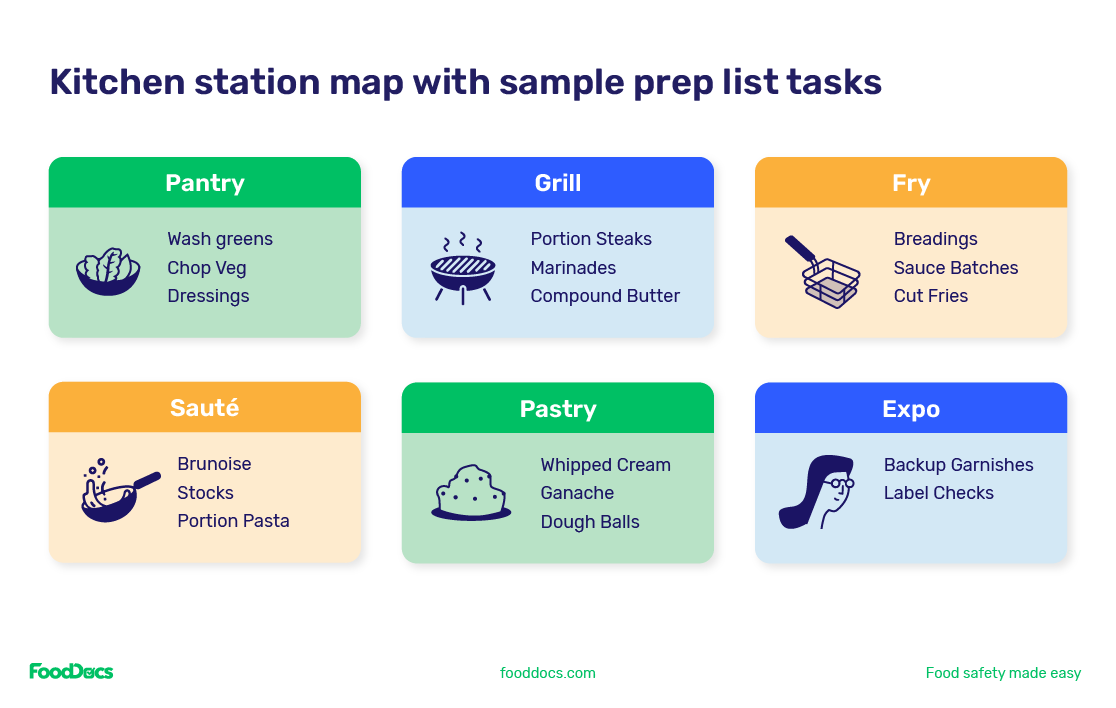

Now, organize the list in a way that suits your kitchen. Some kitchens organize prep lists by station, e.g., Pantry (salads, cold apps) has its own prep list, Hot Line (grill, sauté) has another, and pastry has another. Others make one big list but group it by category. Choose what ensures clarity for your team because the goal is to make it easy for everyone to find their tasks on the list.

2. Set realistic par levels for each item

The second (and arguably more tricky) component is determining par levels for all those prep items. Setting the right pars is crucial for controlling food cost and avoiding waste. But how do you decide on the numbers?

If your restaurant is brand new, you’ll have to make educated guesses at first. Start with conservative estimates for each item (perhaps based on seating capacity and a bit of market research or chef’s intuition), then adjust after a few weeks once you see actual sales.

It’ll take about 3-4 weeks to gauge the proper par levels in a new restaurant operation. During those first weeks, track how much of each item you actually use and note patterns.

For established operations, use historical sales data. Look at your POS reports or sales logs: how many of each entree, side, soup, or dessert do you sell on typical days?

If Fridays are busy and you sell 50 burgers, ensure the prep list covers at least 50 burger setups (buns, patties formed, veggies sliced, etc.). If the crème brûlée dessert rarely sells on Wednesdays, you’ll know to prep fewer of them mid-week.

On the flip side, if you keep running out of the soup of the day by Sunday evening, that’s a sign the par for soup on Sundays should be higher. Par level setting is iterative: you increase or decrease targets as you observe trends.

Finally, document these par levels clearly on the prep list (and update them when they change). When everyone knows the targets, they can prep with confidence.

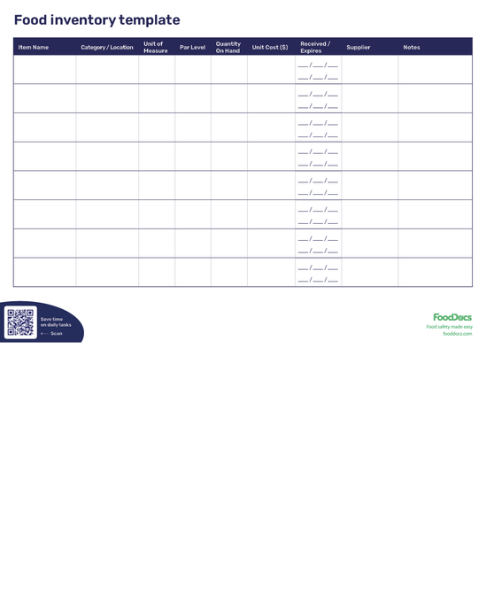

Get your free restaurant food and equipment inventory template

What are some tips for keeping your team consistent when calculating yields, scaling batches and making conversions?

Put the math in one place so anyone can scale a recipe or a par.

Quick conversions

- 1 gallon equals 16 cups

- 1 cup equals 8 fluid ounces

- 1 pound of diced onion equals ~3 cups

- 1 bunch of chopped parsley equals ~1 cup (loose)

Scaling tip

- Add a “Portions Needed” cell on your sheet

- Let a formula fill “To Prep” based on portions

- Link it to expected covers or reservations

Yield notes

- Record how much a batch makes after trim or cook off

- Update your recipe card so the next batch is accurate

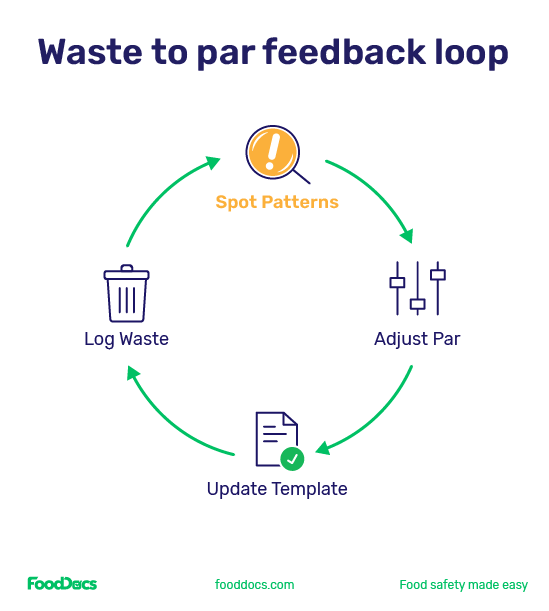

How can keeping a waste log and par tuning support an effective kitchen prep list?

A small restaurant waste log will pay for itself in a week.

Track:

- Item

- Amount tossed

- Reason

- Shift

- Cook initials

Tune pars weekly:

- If you toss it two days in a row, drop the par

- If you run out to days in a row, raise the par

- Recheck after one week and lock the new par

How can FoodDocs' software support your kitchen prep tasks?

Digital restaurant prep lists mean easier monitoring and compliance.

FoodDocs’ digital restaurant Food Safety Management System, which includes features perfectly suited for managing kitchen prep lists, cleaning checklists, food temperature logs, and more. The restaurant software uses smart automation to create digital monitoring logs and checklists tailored to your exact operations, with full customizability (if needed).

For example, when setting up FoodDocs for your restaurant, you could have it produce a daily “Kitchen Prep Tasks” checklist as part of your food safety routine. This checklist would live in the FoodDocs mobile app, and your prep cooks could tick off tasks on their smartphone or tablet as soon as they’re completed.

Restaurant Managers and Executive Chefs can also assign tasks to specific team members based on their roles. During the setup, you can specify which tasks go to which station or cook, and each person will see only the tasks relevant to them on a given day.

This role-based approach means a prep cook in the pastry section isn’t distracted by prep tasks for the grill station, and vice versa. It brings clarity and accountability: everyone knows their duties, and managers can see at a glance who’s responsible for each item.

FoodDocs also integrates educational instructions and media into the checklists. All digital logs and checklists come with built-in step-by-step instructions on how to perform the tasks correctly. You can even upload your own photos or training videos for your recipes and prep tasks.

This is helpful for maintaining consistency and training new staff. Imagine a new prep cook being able to tap on a task in the app (say, “Prep Hollandaise Sauce”) and instantly see the recipe card or a short video of the head chef demonstrating the steps.

FoodDocs’ Smart Recipe Book feature is essentially a digital recipe library that complements the prep list by ensuring your team has all the preparation instructions and recipes at their fingertips.

Recipes can be organized and stored in the cloud, complete with allergen info and even photos of each step, so your crew always follows the same standards.

This not only saves time on training, but ensures that the quality of prepped components (sauces, mixes, batters, etc.) is consistent no matter who is on duty.

Organization is the foundation of great cooking. When you master your kitchen prep lists (and leverage digital tools to enhance them), you’re setting your team up for success before the first ticket of the night even prints.

Try FoodDocs with a 14-day free trial!

Frequently asked questions about kitchen prep lists

Do I need due times or just priorities?

Use both. Add a due time for items that must chill or set before service. Add a simple priority tag like 1, 2, or 3 so cooks know what to start first.

What if we fall behind on kitchen prep?

Triage by menu mix. Finish high sellers first. Batch partials if time is tight. Ask a nearby station for a hand. Buy a short term backup only if it keeps service steady.

How do I forecast pars for events or weather swings?

Start with covers times average portions per item. Add a small bump for events or hot days if cold items sell more. Write the change on the sheet and review it the next day.

How do I stage kitchen prep so it finishes on time?

Start long lead tasks first. Get ice baths ready before hot batches begin. Move items that need chilling up the list so they are cold by line set.

What belongs on a monthly kitchen prep day?

Do deep batches and base work. Stocks, demi, spice blends, infusions, pickles, frozen sauces, and doughs. Add a calendar reminder so it never slips.

How do I handle items near the use by date?

Move them to the front of the line. Use in staff meals or a special the same day if allowed. If it is not safe or does not fit the menu, log it as waste and toss it.

What if an allergen item was prepped in the wrong area?

Treat it as cross contact. Discard the batch. Wash, rinse, and sanitize tools and surfaces. Reset the clean zone. Re prep with the right setup and log the incident.

Can I add simple color alerts in sheets?

Use conditional formatting. If To Prep is greater than zero, highlight the cell. If the due time is past now, turn it red. Keep it simple so cooks can read it fast.

How many prep cooks do I need on a given day?

Add up prep minutes for the day. Divide by the minutes before line set. That gives you heads needed. For example: with 900 minutes of work and 150 minutes available, you need six people.

What should I track each week to improve my kitchen prep list and processes?

Track waste cost, stockouts, late tasks, and overtime minutes. Adjust par levels and staffing based on those numbers. Small changes each week add up.

What if food cooling times are not met?

Reheat to one hundred sixty five and cool again with shallow pans and ice baths. If you cannot, discard it.

What is the minimum prep list column set for a small kitchen team?

Use five fields if space is tight. Item, Par, On Hand, To Prep, Assigned To. Add a notes line at the bottom for due times and storage.

What are best practices for using a kitchen prep list in Microsoft Excel or Google Sheets?

Many teams start with a spreadsheet. Keep it simple so cooks use it.

Setup tips

- Freeze the header row (i.e., usually Row 1)

- Use drop-downs for storage and allergen flags

- Add a “To prep” formula par minus on hand

- Print one page wide with large fonts for posting

- Keep a master sheet and duplicate a fresh copy each day

Google Sheets advantage

- Share with managers

- Real-time edits

- Quick mobile viewing

Save a PDF version for a clean printable.