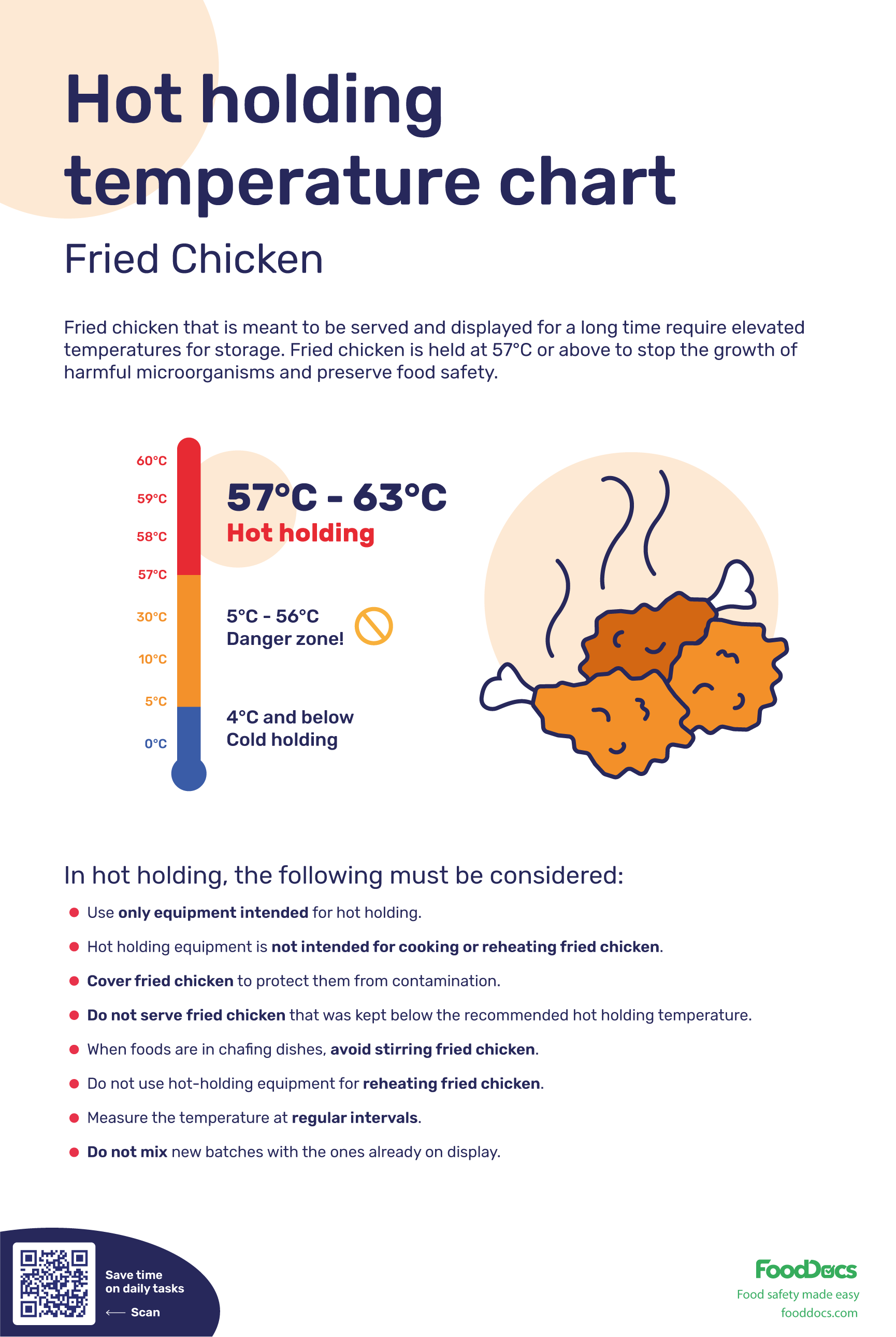

HOT HOLDING TEMPERATURE CHART FOR FRIED CHICKEN

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

What is the minimum hot holding temperature for fried chicken?

Fried chicken is one of the all-time favorite cooked meals for every family and is a hit item in restaurants. It is a straightforward meal to make. Despite this, many food safety operations must be performed to keep it safe from contamination and spoilage. Restaurants are always regulated to cook the fried chicken to the correct internal cooking temp to ensure that it will not cause any foodborne illness. To keep its freshness and safety when serving and displaying for later service, it has to be held at a heated temperature. Food handlers must be aware of what is the minimum hot holding temperature for fried chicken and how to properly maintain it using a guide and a digital thermometer.

Each year, more than half of the recorded foodborne illness outbreaks to the CDC originate from food restaurants as a result of violations of food safety regulations. These outbreaks may have been caused by inadequate food safety practices which include hot holding and incorrect humidity settings. It is part of every food business owner's responsibility to acquaint their food employees with how to properly handle food and devise a way to effectively monitor operations. This is especially true when it comes to food establishments that handle high-risk food products such as poultry and fried chicken.

In this article, find out what is the minimum hot holding temperature for fried chicken and how to effectively monitor the process.

What is hot holding?

Hot holding refers to the operation of holding hot foods at an elevated safe temperature in designated containers to prevent the growth of pathogens and food spoilage. This operation requires a specific hot holding temperature requirement of 57°C and above in hot holding basic cabinet options. The majority of bacteria and other significant foodborne pathogens cannot grow well in this temperature condition and cannot spoil food supplies fast.

The main principle of hot holding food safety temperatures is to prevent foods from being exposed to the temperature danger zone or the minimum temperature range at which foodborne pathogens such as the majority of harmful bacteria grow fastest. Hot holding is commonly used for foods meant to be displayed before consumption, such as in catering services or cafeterias. This also applies to temperature and time control for safety food or TCS food and ready-to-eat foods which can be very prone to spoilage.

Hot holding is different from cooking. While cooking uses very high temperatures with a target core temperature, hot holding only aims to keep the food hot enough to prevent bacterial growth or potential contamination. The cooking process was designed to reduce bacterial levels, whereas hot holding is for prevention.

What is the minimum hot holding temperature for fried chicken?

Properly cooked fried chicken must be displayed at a hot holding temperature of 57°C - 63°C. This safe temperature range ensures that the fried chicken served on display will not have an environment that will promote germ growth, spoil it, and cause foodborne illnesses.

Chicken and other poultry products are considered TCS types of food along with leafy greens, seafood, other meat-based foods, dairy products (e.g. cheese sticks and milk), and plant foods. This means that the temperature adherence around them and the storage time must be closely controlled and monitored. This is because poultry dishes are very high in nutrition and can serve as a good breeding ground for pathogens such as harmful germs, especially at an optimal temperature. In incorrect minimal temperature requirement conditions, the risk of making food unsafe and causing foodborne illnesses increases.

This correct temperature gradient was purely designed to prevent the growth of bacteria and has nothing to do with the quality of fried chicken. As such, the chicken must be properly cooked to prevent the reabsorption of moisture at 57°C - 63°C.

Who needs to monitor the hot holding temperature of fried chicken?

Fried chicken is a very common menu component and a great protein source in a restaurant menu. Restaurants, food trucks, cafeterias, and other food businesses can use a hot holding temperature chart for fried chicken to maintain safety. This chart can become an integral part of your food safety management system documentation if you feature fried chicken on your menu. It can also be used as proof of your strict approach to food safety in case of a food safety inspection is due.

Why should you monitor the hot holding time and temperature for fried chicken?

Fried chicken, including chicken strips and chicken wings, is a very popular dish around the globe. Depending on the process of cooking used, ingredients for coating, and complementary sides, fried chicken is undeniably a star dish. Despite the deliciousness of fried chicken, it is very prone to food spoilage and may cause foodborne illness to consumers. Chicken or any type of poultry is known to be an excellent growing medium and a common source of foodborne bacteria such as Salmonella which makes food unfit for consumption. They need to be thoroughly cooked to the correct internal cooking temperature.

In addition to cooking, they also need to be held at an elevated consistent temperature to maintain their safety and prevent serving hazardous foods. After chicken dishes have been appropriately fried to safe cooking temperatures, they still need to be stored at hot holding food temperatures. This is to prevent the introduction of contaminating bacteria and disallow their growth. Hot holding to keep food warm is a vital food safety operation in combination with other safe food handling practices.

Monitoring the hot holding temperature of fried chicken using a food thermometer in FWE / food warming equipment and containers with a dedicated heat source such as a chafing dish will allow a food service operator to evaluate whether the served food is still safe. Ideally, fried chicken must only be hot held for a maximum of 2 to 4 hours of holding time, depending on the implemented hot holding temperature. The higher the utilized hot holding temperature, the longer you can keep your fried chicken.

In some operations, hot holding is also performed to uphold the quality of fried chicken. Although lower hot holding temperatures can keep the food safe, it allows for moisture to move out of the food items and into its exterior portion. This makes the product softer, an unideal characteristic of fried chicken. At higher temperatures, the quality of fried chicken can be maintained during hot holding.

What are the benefits of a hot holding temperature chart?

A hot holding temperature chart can serve as a general guide for food handlers. It contains the most critical information when it comes to the storage conditions for highly perishable products such as fried chicken. Specifically, this chart can help achieve the following benefits:

- Food safety. The main objective of this chart is to protect customers from the considerable food poisoning risks of storing fried chicken at the wrong storage temperature and serving cold meals. In unsuitable temperature conditions, highly perishable items such as fried chicken can spoil very fast and cause foodborne illnesses to consumers. With proper guidance, food handlers can create a safe environment for every customer and ensure serving only safe food.

- Food safety training. Hot holding is a part of the very long list of food safety practices that every food handler must be aware of and well-versed in. A hot holding temperature chart can be used to orient food handlers regarding the significance of the hot holding operation as well as the potential consequences of non-compliance. A food business owner can use this tool to properly facilitate learning and ensure that accurate information is used to teach food handlers.

- Cost-saving. When food handlers are all aware of the important food safety practices and how to perform them correctly, your food business becomes secure from food safety issues. These issues can be potentially damaging to your food business and a threat to health safety as they will not only affect customers' perception of your services but their confidence in your approach to food safety as well. Additionally, food safety issues can escalate into damaging lawsuits when situations such as foodborne illness outbreaks arise. The risk of damage can potentially stop your business operations.

- Quality maintenance. For most food products, hot holding is not just performed for food safety but for the quality of hot meals as well. The hot-holding temperature threshold and proper humidity levels protect foods such as fried chicken from losing their desirable eating characteristics. A higher range of temperatures of hot holding prevents foods from reabsorbing moisture during storage, making the texture go bad and even initiating germ growth.

The hot holding temperature chart for fried chicken is just one of our food safety documents at FoodDocs. In our HACCP plan template hub, we have made and collected the most important food safety guidelines and documents that can be used for your food business. These documents can complement and complete your food safety management system in guiding food handlers on proper food safety operations.

Find out and use our list of templates, checklists, monitoring forms, posters, and consumer advisories. The best part about these tools is that they are completely free! Download, print, and use them for free to improve your food safety team's operations.

To help you further understand topics on what is the minimum hot holding temperature for fried chicken, here are a few related questions:

- What is the minimum holding temperature of fried chicken on a buffet table?

The minimum temperature requirement for holding a fried chicken on a buffet table is 57°C. At this temperature, most foodborne pathogens will not be able to multiply fast enough to spoil foods.

- What is the minimum internal cooking temperature for chicken and how long must it hold that temp?

For hot holding to become effective, chicken and other poultry products must be cooked to an internal temperature of 74°C for at least 30 seconds.

How can you help your team to monitor hot holding?

Hot holding can only become effective if it is consistently applied and monitored with constant operator observation at the same time. When the hot holding temperature for foods is inaccurately maintained for a long time without being able to detect temperature fluctuations or if the temperature of food falls into the temp danger zone, the problem can increase the risk of food poisoning and can put your customers in a dire situation. This is why operations such as properly calibrating kitchen thermometers used for measuring hot holding temperatures are important as well as keeping an accurate temperature reading record for food safety.

The problem is, that monitoring hot holding temperature is not an easy task as it needs to be done for every warming equipment and type of food. Food handlers must dedicate their time to monitoring the temperature which needs to be done every one to two hours for consistency. The more frequent the temperature monitoring, the faster food handlers can apply appropriate corrective actions.

With the dawn of technological advancements in the food industry, advanced solutions have started to offer more convenient ways of controlling food safety. Your best bet to become onboard with the digital age is to use digital Food Safety Management System.

Digital system makes hot holding temperature easier and reduces the need to manually do everything. Using artificial intelligence, our system can automatically generate a digital FSMS complete with intuitive monitoring systems based specifically on your food safety operations.

How can our system help you in your hot holding monitoring tasks?

Here are some of the main features that FoodDocs offers:

-

Easily monitor and find your food products using a QR code scanner featured in our system. This feature will show the most updated status of the scanned product for quick assessments and decision-making.

-

Our hot holding temperature monitoring forms are automatically filled based on your previous monitoring logs. This increases the accuracy of your data entries and reduces the time needed to fill-out forms. Simply instruct employees on how to verify the information and ensure correctness.

-

Our system is equipped with an intuitive timer which you can set for every hot held food. Once the food has reached the maximum time, our system will send smart notifications to remove it from hot holding.

-

In case of non-compliant temperature readings, our system automatically suggests appropriate corrective actions. The list of corrective actions can be further customized in the account setup. A food worker should be guided accordingly on how and when to apply these corrective actions.

How to use our hot holding features at FoodDocs?

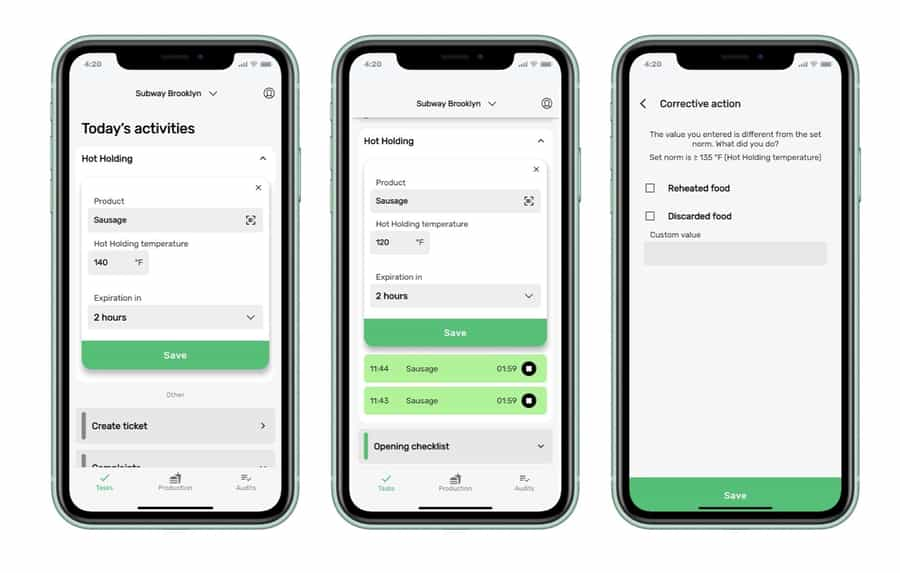

Using our mobile application, you can easily keep track of every perishable food under hot holding. Follow these easy steps to ensure food safety:

Step 1: Select a product or easily find it with the QR scanner;

Step 2: Insert the hot holding temperature or use our automated temperature pre-filling solution. If the temperature is incorrect, the app will ask you to insert the corrective action

Step 3: Track the hot holding duration with the expiration timer. FoodDocs app will automatically send a notification when the food should be removed from the hot hold.

In addition to these hot holding-specific features, our system also offers a real-time dashboard that can give you a quick overview of your food safety operations progress. This feature can be used to save at least 20% of your time from supervising every operation yourself. Additionally, you also get cloud storage where you can secure every digital food safety document in your food business.

Our digital FSMS was built to make food safety compliance such as temperature adherence easy and not complicated at all. As long-time food safety practitioners, our team understands the need for a system that is efficient and can speed up the process of achieving food safety.

Become more sustainable by ditching the traditional, paper-based FSMS and switching to our digital platform. In just an average of 15 minutes, you can get a thorough system that will help you ensure that every food safety operation is fulfilled on time and correctly.

Experience the convenience that our system offers now. Avail of our free, 14-day trial which you can use to explore every food safety feature of our system free. Build your digital FSMS in just an average of 15 minutes now.