5 WHYS ROOT CAUSE ANALYSIS TEMPLATE | FREE DOWNLOAD

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

The 5 Whys is a simple yet powerful problem-solving technique that helps identify the root cause of an issue by asking "why" five times.

This method is particularly valuable in the food service and production industries, where understanding and addressing the root causes of food safety issues can prevent recurrences and ensure compliance with regulations.

This guide will walk you through the 5 Whys process, provide practical examples, and offer a free downloadable 5 Whys Root Cause Analysis template to help you implement this technique effectively.

Key takeaways

-

The 5 Whys is a technique developed by Sakichi Toyoda to identify the root cause of a problem by asking "why" five times.

-

In food safety, the 5 Whys helps managers identify and address root causes of issues like contamination and equipment failures.

-

Root cause analysis (RCA) is essential in food safety for identifying underlying causes of outbreaks and contamination incidents.

-

Preparing for a 5 Whys RCA involves assessing capacity, developing plans, training staff, and conducting exercises.

-

The 5 Whys process includes defining the problem, asking "why" five times, analyzing the root cause, developing a solution, and implementing it.

-

Effective communication of 5 Whys findings is crucial for preventing future incidents and involves transparent reporting and stakeholder engagement.

-

Examples of 5 Whys in food safety include contamination issues and equipment failures, where root causes like improper training or maintenance are identified.

-

Benefits of the 5 Whys include improved problem-solving, enhanced food safety, cost savings, and increased efficiency.

-

Best practices for implementing the 5 Whys include involving the right people, being objective, documenting everything, and regularly reviewing procedures.

-

Limitations of the 5 Whys method include oversimplification, subjectivity, and incompleteness, making it less suitable for complex systems.

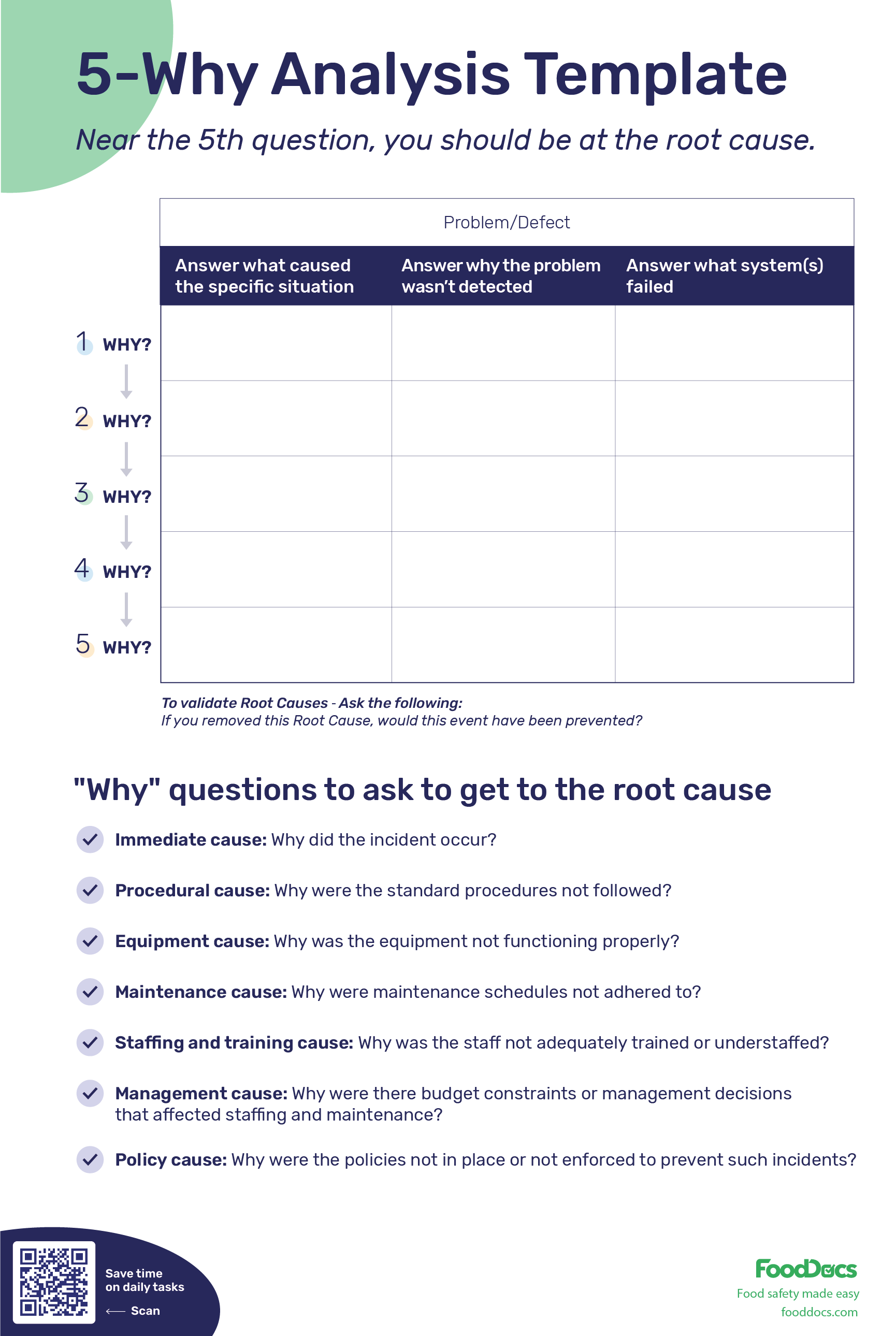

Download your free 5 Whys template

To help you implement the 5 Whys in your food safety management, we've created a free downloadable template which includes a:

- Problem statement section

- 5 Whys analysis table

- Root cause identification section

- Starter questions

The 5 Whys is a powerful tool for identifying and addressing the root causes of food safety issues. Following the steps outlined in this guide and using the provided template will help make implementing the 5 Whys in your food safety management practices more effective.

What are the 5 Whys?

The 5 Whys is a straightforward technique developed by Sakichi Toyoda, the founder of Toyota. It involves asking "why" five times to get to the root cause of a problem. This method is based on the idea that by repeatedly asking why, you can peel away the layers of symptoms that can lead you to the underlying cause of the problem.

Why use the 5 Whys technique in food safety?

In the food industry, ensuring safety is paramount. The 5 Whys can help food safety managers and handlers identify the root causes of issues such as cross-contamination in food, equipment failures, and procedural errors. Addressing these root causes allows you to implement effective solutions that prevent future incidents.

What's the importance of root cause analysis in food safety?

Root cause analysis (RCA) is a crucial tool in the food safety industry, helping to identify the underlying causes of foodborne illness outbreaks and contamination incidents. Understanding and addressing these root causes helps food safety managers prevent recurrences and ensure the safety of the food supply chain.

RCA is particularly important since food production and distribution systems are scaling and, many times, becoming more complex and globalized. Traditional methods of food safety management, such as manual inspections and paper-based record-keeping, are often insufficient to address the challenges posed by modern food systems.

Root cause analysis provides a systematic and data-driven, more scientific approach to identifying and addressing food safety issues, making it an essential tool for food safety managers, directors of operations, and food handlers.

How to prepare for a 5 Whys Root Cause Analysis

Before conducting your 5 Whys RCA, take some time to prepare adequately. Depending on your level of preparedness, this could involve several key steps:

- Assessing capacity: Evaluate the current capacity to conduct RCA for different types of food safety incidents. Determine the number of adequately trained and experienced staff available and identify any gaps in capacity.

- Developing plans and procedures: Develop plans and procedures for conducting RCA, including identifying the necessary resources, such as staff, equipment, and training materials.

- Training staff: Provide training to ensure designated staff have the expertise and familiarity to function effectively as a team. This includes foundational principles, recognizing indicators of when investigation scale-up is warranted, and making appropriate notifications to initiate the expansion when needed.

- Conducting exercises: Conduct exercises to evaluate capacities and build experience by partnering experienced staff with less experienced staff during investigations.

Step-by-step guide to implementing the 5 Whys

Step 1: Define the problem

The first step is to clearly define the problem you are trying to solve. Be specific and concise in your description. For example, instead of saying "there is a contamination issue," say "there is an E. coli contamination in the salad dressing production line."

Step 2: Ask "why" five times

Once you have defined the problem, start asking "why" to drill down to the root cause. Here is an example of how this might look in a food safety context:

- Why did the salad dressing become contaminated with E. coli?

- Because the ingredients were not properly sanitized.

- Why were the ingredients not properly sanitized?

- Because the sanitization procedure was not followed correctly.

- Why was the sanitization procedure not followed correctly?

- Because the staff was not adequately trained on the procedure.

- Why was the staff not adequately trained on the procedure?

- Because the training program was outdated and ineffective.

- Why was the training program outdated and ineffective?

- Because there was no regular review and update of the training materials.

Step 3: Analyze the root cause

After asking "why" five times, you should have a deep understanding of the root cause. In the example above, the root cause is the lack of regular review and update of the training materials.

Step 4: Develop a solution

Based on your analysis, develop a solution that addresses the root cause. In this case, the solution might be to establish a regular review process for training materials and ensure that staff receive up-to-date training on sanitization procedures.

Step 5: Implement and monitor

Implement the solution and monitor its effectiveness. Ensure that the problem does not recur by regularly reviewing and updating your procedures.

How to communicate your 5 Whys Root Cause Analysis findings

Communicating your 5 Whys RCA findings effectively is crucial for preventing future incidents and improving food safety practices. Here are some best practices for communicating RCA findings:

- Transparent reporting: Provide a transparent and detailed report of the Root Cause Analysis findings, including the problem statement, the "why" questions, the root cause, and the proposed solution.

- Stakeholder engagement: Engage stakeholders, including suppliers, regulators, and consumers, in the communication process. This includes providing regular updates and seeking feedback.

- Clear and concise messaging: Use clear and concise language to communicate complex causal relationships. Avoid jargon and technical terms that may not be understood by all stakeholders.

- Visual aids: Use visual aids, such as diagrams and charts, to illustrate the root cause and the proposed solution. This can help stakeholders better understand the findings and the actions needed to address the root cause.

- Action plan: Develop an action plan based on the Root Cause Analysis findings and communicate this plan to all relevant stakeholders. This includes setting timelines, assigning responsibilities, and monitoring progress.

What are 5-Why examples in food safety?

5 Whys example 1: Contamination in Food Processing

Problem: Contamination of chicken products with Salmonella.

5 Whys Analysis:

- Why was there Salmonella contamination in the chicken products?

- Because the chicken was not cooked to the required food temperature.

- Why was the chicken not cooked to the required temperature?

- Because the oven temperature was not calibrated correctly.

- Why was the oven temperature not calibrated correctly?

- Because the maintenance schedule was not followed.

- Why was the maintenance schedule not followed?

- Because the maintenance team was understaffed.

- Why was the maintenance team understaffed?

- Because there was a lack of budget allocation for maintenance personnel.

Solution: Allocate a budget for hiring additional maintenance personnel and ensure that the maintenance schedule is strictly followed.

5 Whys example 2: Equipment failure

Problem: Equipment failure leading to a shutdown in the production line.

5 Whys Analysis:

- Why did the equipment fail?

- Because it was not properly maintained.

- Why was it not properly maintained?

- Because the equipment maintenance logs were not up-to-date.

- Why were the maintenance logs not up-to-date?

- Because the staff was not trained on the importance of maintaining accurate logs.

- Why was the staff not trained on the importance of maintaining accurate logs?

- Because the training program did not cover this aspect.

- Why did the training program not cover this aspect?

- Because the training program was not reviewed and updated regularly.

Solution: Review and update the training program to include the importance of maintaining accurate maintenance logs and ensure that staff are adequately trained.

What are the benefits of conducting a 5 Whys Root Cause Analysis?

The 5 Whys root cause analysis process offers numerous advantages that can significantly enhance food safety management. We put together 15 high-level benefits of using the 5 Whys technique:

- Improved problem-solving: The 5 Whys method helps safety managers and food handlers identify the root cause of problems, rather than just addressing the surface-level symptoms. This leads to more effective and lasting solutions.

- Enhanced food safety: By addressing the root causes of food safety issues, you can prevent future issues and ensure that your products are safe for consumption. This is crucial for maintaining consumer trust and food safety compliance with regulations.

- Cost savings: Preventing food safety issues can save your company significant costs associated with recalls, lawsuits, and damage to reputation. The 5 Whys helps you identify and address potential problems before they escalate.

- Increased efficiency: The 5 Whys process is straightforward and can be implemented quickly. It does not require complex tools or extensive training, making it an efficient problem-solving technique for the food industry.

- Better training and education: By identifying the root causes of problems, you can develop targeted food safety training programs that address specific issues. This ensures that your staff is adequately prepared to handle food safety challenges.

- Continuous improvement: The 5 Whys encourages a culture of continuous improvement. By regularly reviewing and updating your procedures based on the root cause analysis, you can continually enhance your food safety practices.

- Increased transparency: The 5 Whys process promotes transparency by involving different departments and stakeholders in the problem-solving process. This ensures that everyone is aware of the issues and the steps being taken to address them.

- Regulatory compliance: Addressing the root causes of food safety issues helps you meet regulatory requirements and demonstrate your commitment to food safety. This can lead to fewer inspections and penalties.

- Enhanced consumer trust: By ensuring that your food products are safe and addressing any issues promptly, you build consumer trust. This is crucial for maintaining your brand's reputation and market success.

- Data-driven decision-making process: The 5 Whys process relies on data and evidence to identify the root causes of problems. This ensures that your informed decisions are based on facts, rather than assumptions or guesses.

- Proactive approach: The 5 Whys encourages a proactive approach to food safety management. By identifying and addressing potential issues before they become major problems, you can prevent incidents and ensure the safety of your products.

- Employee empowerment: Involving employees in the 5 Whys process empowers them to take ownership of food safety issues. This leads to a more engaged and motivated workforce, which is crucial for maintaining high standards of food safety.

- Reduced waste: By preventing food safety issues, you can reduce waste associated with recalls, spoilage, and other problems. This leads to cost savings and a more sustainable operation.

- Better resource allocation: The 5 Whys helps you identify the most critical areas that need attention. This ensures that your resources are allocated effectively, leading to better outcomes and cost savings.

- Enhanced collaboration: The 5 Whys process involves collaboration between different departments and stakeholders. This leads to better communication, coordination, and a more integrated approach to food safety management.

Implementing the 5 Whys process will help ensure that your products are safe, compliant with regulations, and trusted by consumers.

What are the best practices for a successful implementation of the 5 Whys?

There are four things you can do to help ensure the success of your 5 Whys Root Cause Analysis:

Involve the right people

Ensure that the team involved in the 5 Whys analysis includes people from different departments who have relevant knowledge and experience. This will provide a more comprehensive understanding of the problem.

Be objective and open-minded

Avoid blaming individuals or departments. The goal is to identify the root cause, not to assign blame. Be open to different perspectives and ideas.

Document everything

Keep detailed records of the 5 Whys analysis, including the problem statement, the "why" questions, the root cause, and the proposed solution. This documentation will be useful for future reference and continuous improvement.

Regularly review and update

Food safety is an ongoing process. Regularly review and update your procedures and training programs to ensure that they remain effective and relevant.

What are the problems of the 5 Whys method?

The 5 Whys root cause analysis is widely taught and promoted in the food industry due to its simplicity and pedagogical value. However, depending on your specific operations, it can have some limitations that make it an inadequate tool for root cause analysis in food safety.

Oversimplification and Limited Scope

The 5 Whys method forces users down a single analytical pathway, focusing on a single root cause. This oversimplification ignores the complex and interconnected nature of real-world problems, which often have multiple causes. By limiting the analysis to five "why" questions, the method may miss critical contributing factors and systemic issues.

Example: In a food processing plant, a batch of contaminated salad dressing is identified. Using the 5 Whys method, the analysis might conclude that the contamination was due to a single root cause, such as inadequate training of staff on sanitation procedures. However, this oversimplification ignores other potential contributing factors, such as equipment malfunctions, supply chain issues, or environmental contaminants.

Subjectivity and Lack of Evidence

The effectiveness of the 5 Whys method depends heavily on the knowledge and experience of the person conducting the analysis. Different individuals may arrive at different root causes based on their perspectives and biases. Additionally, the method relies on iterative questioning rather than empirical evidence, leading to speculation and assumptions rather than data-driven conclusions.

Example: Two different food safety teams analyze the same contamination incident but arrive at different root causes. One team might identify poor temperature control as the root cause, while another might point to inadequate storage practices. This subjectivity highlights the reliance on individual knowledge and experience rather than empirical evidence.

Incomplete Analysis

The 5 Whys method may stop at the first plausible root cause, resulting in an incomplete analysis. This can lead to addressing symptoms rather than the underlying issues. The method does not include a validation step to confirm that the identified root cause is indeed the primary cause of the problem.

Example: A food manufacturer experiences a recall due to foreign objects found in the product. The 5 Whys analysis might stop at the first plausible root cause, such as a lack of metal detectors in the production line. However, this incomplete analysis fails to address other potential contributing factors, such as inadequate maintenance of equipment or insufficient quality control checks.

Single Root Cause Focus

The 5 Whys method insists on a single root cause as the target for solutions, assuming that the most distal link on the causal pathway (the fifth "why") is inherently the most effective and efficient place to intervene. However, accidents are seldom the result of a single root cause, and focusing exclusively on one arbitrarily determined root cause is not a reliable method for driving improvement.

Example: In a restaurant, a foodborne illness outbreak is traced back to cross-contamination. The 5 Whys analysis might identify the root cause as improper handwashing practices by staff. However, focusing exclusively on this single root cause overlooks other contributing factors, such as inadequate kitchen design, insufficient training, or lack of proper sanitization protocols.

Inadequate for Complex Systems

The 5 Whys method is not suitable for complex systems where the relationships between causes and effects are not linear. It fails to capture the systemic and organizational factors that contribute to problems, making it less effective in industries with highly complex and interconnected systems, such as the food industry.

Example: A large-scale food recall affects multiple products and suppliers. The 5 Whys method may struggle to capture the systemic and organizational factors that contribute to such complex incidents, such as supply chain vulnerabilities, regulatory compliance issues, or communication breakdowns between different stakeholders.

Pedagogical Value vs. Practical Application

While the 5 Whys method can be a powerful teaching tool, illustrating the need for depth and breadth in analyzing complex problems, its practical application in root cause analysis is deeply flawed. It oversimplifies the process of problem exploration and fails to provide a comprehensive understanding of the underlying issues.

Example: While the 5 Whys method can be a powerful teaching tool in food safety training, illustrating the need for depth and breadth in analyzing complex problems, its practical application in root cause analysis is deeply flawed. It oversimplifies the process of problem exploration and fails to provide a comprehensive understanding of the underlying issues in food safety incidents.

How to conduct a 5 Whys Root Cause Analysis and improve food safety with FoodDocs

Being ready to quickly identify and conduct a 5 Whys Root Cause Analysis will help your food business maintain regulatory compliance in this industry. Food safety regulations vary by region and industry, so it's essential to understand and comply with these regulations. FoodDocs' food safety management software helps you do exactly that.

- Compliance checklists with corrective actions: FoodDocs' digital monitoring checks include corrective actions. If a task is out of range, your team members will get a prompt in the mobile app to guide them on how to respond, ensuring food safety and saving time on training. Use our preset actions or create your own.

- Internal audits: Create, complete, schedule, and manage food safety audits. You'll promote accountability among your team by conducting regular food safety audits to ensure that your business’s food safety standards are high and that, hopefully, you won't ever have to conduct a 5 Whys Root Cause Analysis.

- Food safety training: For every food safety task you create, you can add educational instructions. That way, team members can check the instructions to perform the food safety task correctly. You can use our preset instructions or create your own pictures or videos. This will help you save time on training both new and existing team members.

- Secure document storage: A proper food safety system can consist of hundreds of documents. Everything needs to be stored and found easily in case an inspection or recall. With FoodDocs, you can keep your compliance documents for food inspectors and customers in one place as well as have 24/7 access to your documents so can access them anywhere, anytime.

Frequently asked questions about the 5 Whys Root Cause Analysis

What's the brief history of Root Cause Analysis?

The concept of root cause analysis originated in the manufacturing industry, particularly in the automotive sector. It was developed by Sakichi Toyoda and later refined by Taiichi Ohno, former executive vice president of Toyota Motor Corp.

The Toyota Production System, which incorporated RCA, helped Toyota become one of the world's leading automakers. The success of RCA in the automotive industry led to its adoption in other sectors, including aviation, healthcare, and now the food industry.

In the food industry, RCA has been used to investigate foodborne illness outbreaks and contamination incidents, helping to identify root causes and prevent recurrences. The historical context of RCA underscores its effectiveness in identifying and addressing complex problems, making it a valuable tool for the food safety industry.

What are the common tools for conducting root cause researches?

Several tools can help you conduct an RCA. These tools help organize data, analyze evidence, and identify root causes. Some of the most commonly used tools include:

- Brainstorming: Gather ideas, potential contributing factors, and root causes. This can be structured or unstructured and involves recording ideas on flip charts, index cards, or Post-it Notes.

- Five Whys: A simple, fast problem-solving method that involves asking "why" five times or as many times as necessary until the nature of the incident becomes clear.

- Fishbone diagram (Ishikawa Diagram): A cause-and-effect diagram that visually represents the various categories of factors or events that could have resulted in or contributed to the incident.

- KNOT chart: A tool that allows the investigation team to record all evidence and data collected during brainstorming, interviews, sampling, site visits, etc., and then categorize by know, need to know, opinion, and think we know.

- Fault tree analysis: A deductive procedure that begins with the conclusion and builds potential causes using a fault tree. Events are categorized as the incident, intermediate, basic, and undeveloped events.

How can I improve upon a 5 Whys root cause analysis?

To address the limitations of the 5 Whys method, consider the following recommendations:

- Combine with other tools: Use the 5 Whys method in conjunction with other root cause analysis tools, such as Fishbone diagrams, Causal Tree Diagrams, or Causal Analysis based on Systems Theory (CAST), to gain a more comprehensive understanding of the problem.

- Incorporate data and evidence: Supplement the 5 Whys method with data collection and analysis to ensure that the identified root causes are based on evidence rather than assumptions.

- Involve multiple perspectives: Engage a diverse team with different expertise and perspectives to conduct the root cause analysis. This can help reduce bias and ensure a more thorough investigation.

- Validate findings: Include a validation step to confirm that the identified root causes are indeed the primary causes of the problem. This can involve testing hypotheses and gathering additional data.

- Consider systemic factors: Recognize that many problems have systemic and organizational causes. Conduct a broader analysis to identify these factors and address them accordingly.

- Use more sophisticated techniques: Consider using more systems-focused techniques, such as fishbone or lovebug diagrams, causal tree diagrams, or prospective risk assessment approaches, which can provide a more comprehensive and reliable analysis.