HOW DO YOU CALIBRATE A THERMOMETER?

This is how our Digital Food Safety platform saves 20% of your time on daily tasks:

- Get upcoming task notifications

- Add data into the app

- Check the status of tasks in real-time

When food safety was still handled on paper, I typically spent a couple of hours per day getting the papers and going around checking or completing tasks… Now I can sit down and it's just all there in one place. It takes me 5-10 minutes.

Ruth B.

Store Manager

How to use the thermometer calibration posters?

Concerned food safety practices such as cooking and storage require consistent and accurate temperature measurement and control to become effective and comply with food safety laws. To achieve this, you need to calibrate all your thermometers regularly.

Follow these easy steps to download our thermometer calibration guides:

- Familiarize yourself with both calibration guides.

- Enter a valid email address under the poster you want to download.

- Click "Download." Your downloaded poster will automatically be saved to your Downloads folder.

- Orient all food handlers on the most applicable thermometer calibration method.

To serve as a reference, post the thermometer calibration guides on any visible wall, preferable where the calibration procedure is commonly performed.

Get a more advanced and intuitive solution to recording your calibration information. Use FoodDocs' smart Food Safety Management System and get a digital Calibration Log equipped with step-by-step thermometer calibration instructions.

Using these features, you can ensure that every food handler will conduct the calibration process accurately according to the approved methods.

Key points covered:

- A calibration poster is an important food safety tool that shows the common calibration methods for food businesses.

- The most common calibration methods for thermometers include the boiling point and ice point methods.

- Calibrating thermometers involve the use of a reference thermometer.

- The ideal calibration temperature for the boiling point method is 212°F (100°C), whereas the ideal temperature for the ice point method is 32°F (0°C).

- Thermometers must be calibrated at first use, during consistent use, or when dropped from a distance.

- FoodDocs' smart Food Safety Management System can automatically generate a Calibration Log that you can use to record temperatures.

- Our smart software contains detailed instructions on the two most common calibration methods and can serve as a reference for food handlers.

WHAT WE'LL COVER:

What is a food thermometer calibration guide?

A food thermometer calibration procedure guide is a visual reference on how to properly calibrate a thermometer used in the food supply chain.

A thermometer is a common kitchen equipment used to measure high or low temperatures by food processors and handlers in any food establishment.

Some of the most common thermometer types include the following:

- Digital probe thermometers

- Common dial food thermometer/ Meat thermometer

- Bimetal thermometer

- Analog thermometer

- Pocket thermometers

- Infrared thermometer

- Glass bulb thermometer

An individual thermometer must be assigned for a specific safe temperature range. That is, one food thermometer must be assigned to measure the internal cooking temperature of food products and another separate food thermometer for measuring storage temperatures.

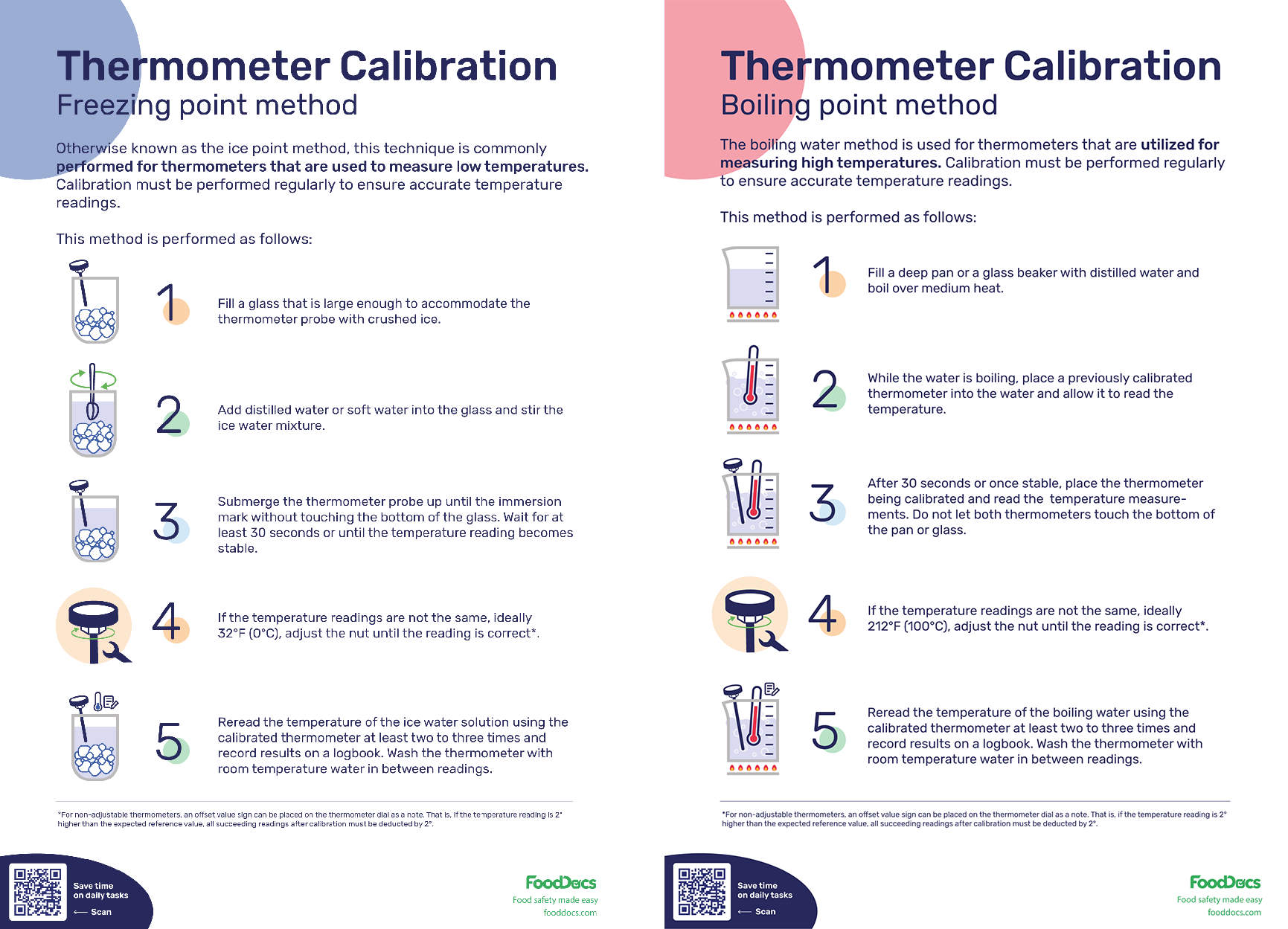

A thermometer calibration guide features two of the most common thermometer calibration procedures: the boiling point or boiling water method and the freezing or ice point method.

Each calibration guide contains detailed step-by-step information on how to operate. The calibration method to use will depend on the type of operations that the thermometer being calibrated is used for. Generally, boiling point calibration tests for hot food and freezing or ice bath tests for cold food.

This guide can help you maintain the accuracy of your temperature readings and ensure food safety in every operation in your food business that requires temperature control.

Get a more advanced guide when you use FoodDocs' smart Food Safety Management System. Our smart software can automatically generate a Thermometer Calibration Log with clear step-by-step instructions on calibrating a thermometer.

With our smart solution, you won't need to print new guides as all instructions are in your smartphones.

How to calibrate a thermometer

Calibrating a thermometer is an important food service operation to ensure accurate temperature readings.

The most effective way to calibrate a thermometer is using any of the following methods:

- Boiling water method

- Ice-point method

The calibration process may vary depending on the type of thermometer at hand. The suitability of the calibration method will also depend on the intended use of the calibrated thermometer.

Here are common steps for both methods of calibration:

- Fill a glass with ice water or a saucepan with boiling water.

- Dip both the reference thermometer and your thermometer into the water.

- Allow the temperature reading to stabilize.

- Read the reference and your thermometer's measurements.

- Adjust the thermometer according to the reference thermometer reading.

- Read and record the temperature again to ensure that the temperature reading matches the reference.

Some steps of the entire process may vary depending on the type of thermometer you are using. This means that you always have to consider the manufacturer's calibration instruction label.

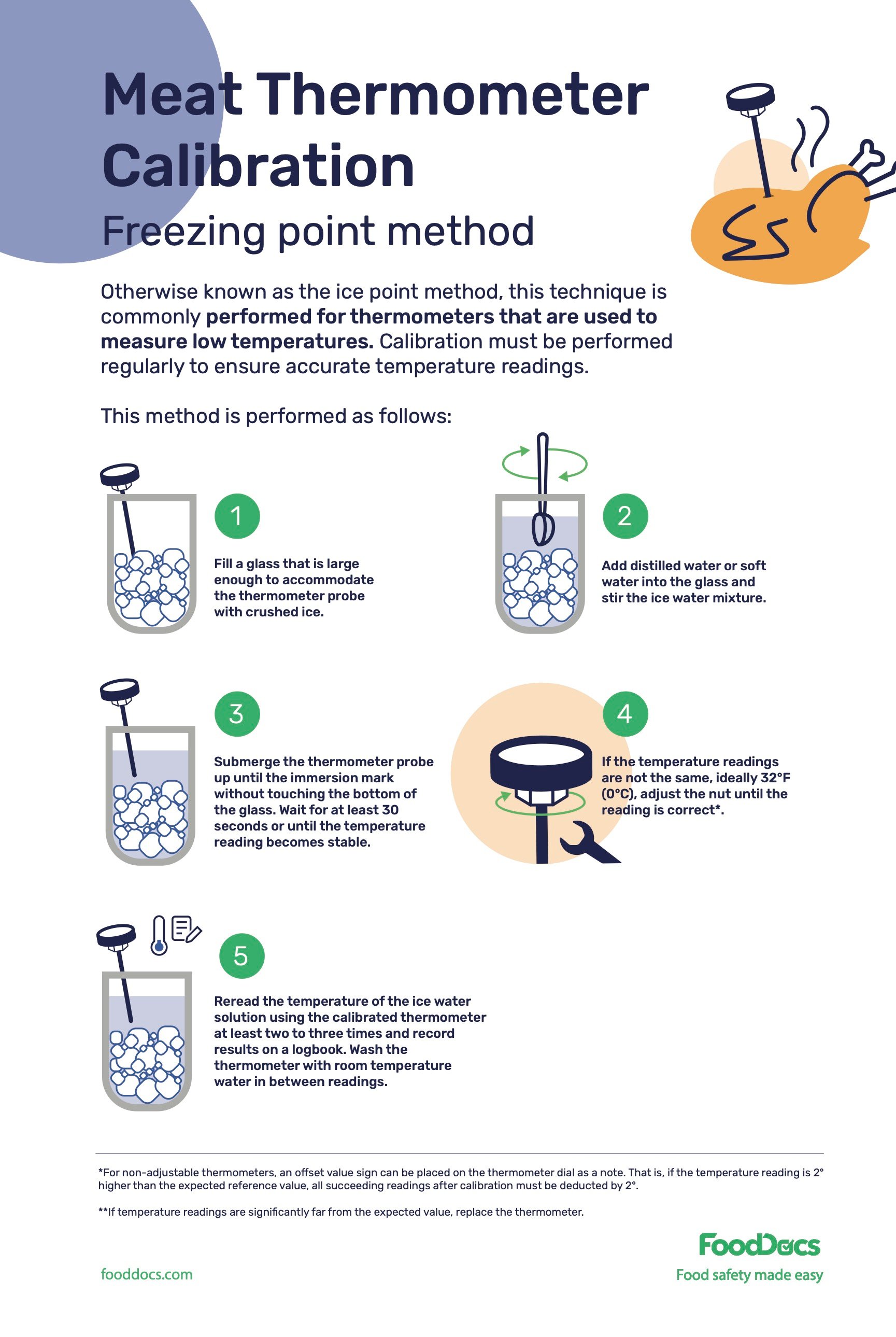

How to calibrate a meat thermometer

A meat thermometer is used to measure the temperature of dishes during cooking. This means that this thermometer is commonly exposed to high temperatures.

As such, the most suitable calibration technique for this type of thermometer is the boiling water method.

Here are the essential steps to calibrate a meat thermometer:

1. Prepare water in a saucepan and bring it to a rolling boil.

2. Submerge the thermometer being calibrated and the reference thermometer into the boiling water.

3. Allow the temperature reading to stabilize and record it.

4. For manual meat thermometers, adjust the calibration nut accordingly. For digital meat thermometers, click the reset or calibrate button.

5. Repeat the temperature reading process and record all measurements.

Remember, accurate temperature readings are vital for food safety. Regularly calibrating your meat thermometer helps ensure that your food is cooked to the appropriate temperature, reducing food safety risks, such as foodborne illnesses.

Calibration can also help you ensure the degree of doneness when cooking meat.

Download our Meat Thermometer Calibration Poster here.

What are the methods on how to calibrate a food thermometer accurately?

- Boiling point method

- Ice point method/ Freezing point method

Each type of calibration process is recommended depending on the intended use of the thermometer. The boiling point calibration method is recommended for thermometers used in cooking, whereas the ice point method is recommended for thermometers used to measure refrigerated temperatures.

Below, we discuss more on how to calibrate your thermometers in detail.

How to calibrate a thermometer with ice and water?

The ice point method is known to be called many different names. This method is also known as the freezing point, cold water, or ice water method.

The idea of this method is to calibrate the thermometer to low temperatures and use a previously calibrated unit as a reference.

- Fill a glass with ice cubes and clean, cold water.

- Stir the ice water solution to achieve an equal temperature.

- Submerge the thermometer stem until the immersion mark. After placement in ice and water, a thermometer should stabilize in about 30 seconds.

- In case of faulty reading, adjust the thermometer according to the reference thermometer's ice water temperature reading.

- Repeat the exact reading and record the measurements until the reading matches.

Some thermometers have an offset value to consider environmental factors. An offset, in the context of thermometers, refers to an additional adjustment in the reading that compensates for the potential impact of environmental elements on temperature measurements. If a thermometer reads as 34°F (1°C), but has an offset of +34°F (1°C), then the reading is actually 36°F (2°C). Always take note of offset values for a more accurate reading.

When using the ice-point method for calibrating thermometers, you should use only distilled water. The purity of the water used for calibration greatly prevents consistent readings.

Thermometers calibrated in a cup of ice water should be set to 32°F (0°C).

How to calibrate a thermometer with boiling water?

The boiling water method is the preferred procedure for calibrating thermometers used during cooking and hot-holding foods.

To calibrate the thermometer, distilled water, a saucepan, a reference thermometer, and a heat source are needed.

- Fill a saucepan with water.

- Bring the water to a boil.

- Use a clamp to submerge the thermometer and reference the hot water. Allow at least 30 seconds to stabilize the reading.

- Adjust the thermometer according to the temperature reading of the reference. Use a wrench to turn the calibration nut.

- Reread the thermometer after calibrating and record the temperature readings.

Thermometers calibrated in boiling water should be set to 212°F (100°C)

Calibrating thermometers used for cooking is a critical task. A few degrees off the target temperature can lead to an undercooked dish, which can cause foodborne illness to consumers.

Regular calibration must be part of every food business's routine to retain compliance with food laws.

What is the correct calibration temperature?

The correct calibration temperature depends on the method being used. The ideal temperature for the boiling point method is at least 212°F (100°C), which is the boiling point temperature of pure water.

On the other hand, the recommended food temperature to reach for the ice point method is 32°F (0°C), which is the freezing point of pure water.

A margin of error or degree difference of about ±1°F or ±0.5°C is allowed to declare a thermometer accurate.

Why do you need to calibrate a thermometer?

Any type of accurate food thermometer may lose its reading accuracy over time. This situation can lead to incorrect temperature readings and increases the risk of allowing harmful bacteria to survive.

- Food safety. An uncalibrated thermometer used for cooking may miss the target internal temperature and lead to overcooking or undercooking. The latter situation can lead to bigger problems, such as causing a foodborne illness outbreak.

- Thermometer maintenance. The loss of accuracy of a thermometer is a natural occurrence. Different reasons, such as frequent extreme temperature changes in targeted readings, can result into this. Regular calibration can help detect potential equipment malfunction and therefore prevent many further problems.

- Consumer confidence. Accurate instruments are keys to maintaining food safety. The safety of your food products and, consequently consumer confidence may depend on how accurate your temperature readings are.

- Quality control. A calibrated thermometer is a must when achieving a consistent quality of food. Accurate temperature readings are essential for cooking meats at a particular level of doneness. Similarly, consistently accurate temperature readings are needed to maintain the temperature of salad bars which are an important component of many food businesses.

- Regulatory compliance. Certain industries, such as food and pharmaceuticals, are subject to regulations that require accurate temperature monitoring and documentation. Calibrating thermometers help ensure compliance with these regulations.

- Cost-saving. In addition, proper calibration can also help your food business save money. An aspect of this benefit is that when your thermometers are always regularly calibrated, the risk of foodborne illness and any other food safety issue is very low. Another aspect of this benefit is that regular calibration helps your team tune-up and detect any problems with your thermometers.

Regularly calibrating thermometers must be a part of every food business's food safety system. Thermometers are essential tools that every food business should have. Over time and use, thermometers can drift away from their original calibration, resulting in inaccurate temperature readings.

Maintain your thermometer's proper calibration through the help of FoodDocs' smart Food Safety Management System. Our intuitive software features detailed instructions, including the two main methods of calibrating accurate thermometers.

Ensure that all employees are properly guided on calibrating thermometers with these instructions.

Who needs to calibrate a thermometer?

Every food business that needs temperature control to maintain food safety would need to know how to calibrate a thermometer. If your food business involves heat processing and cold temperature storage, your team will surely need a calibration guide.

Below are some food businesses that require thermometer calibration and the common tasks that require a thermometer:

- Food services - thermometers are commonly used for cooking foods and refrigeration.

- Food production - thermometers are used in the production of big batches of food.

- Food retail - thermometers are commonly used for cold holding or refrigerating fresh raw materials or cooked foods.

Using our free guides, you can teach food handlers how to calibrate their thermometers properly.

When should thermometers be calibrated?

The frequency of thermometer calibration in your food business depends on your food safety protocols. In some food businesses, thermometer calibration is performed regularly, such as before a shift starts.

A calibration frequency schedule can help a food safety team ensure their operations are always safe.

- When the thermometer is new.

- After not being used for a very long time.

- When the thermometer is used multiple times in a day.

- When the thermometer is dropped.

- When using the thermometer to measure extreme gradients of temperatures (extreme hot to cold temperatures).

- After sanitizing the thermometer.

So how often do you need to calibrate thermometers?

Depending on the type and model of thermometer that you have, reliable thermometer companies may indicate a specific time frame for calibrating thermometers and exact instructions with precise specifications on how to perform the task.

Manufacturers can offer custom thermometer calibration services and a demonstration of thermometer calibration. More sophisticated thermometers, such as digital models, may need the help of expert technicians and would need more than just the regular methods for thermometer calibration.

These types of food thermometers only require calibration quarterly, whereas some only need to be calibrated once a year.

How can you help your team calibrate thermometers?

Temperature calibration logging, along with acquiring accurate food safety information through monitoring, is a very repetitive yet important job.

The actual temperature reading needs to be measured multiple times every day and must be accurately recorded. The information in these monitoring forms proves your team's approach to food safety and commitment to achieving high food safety standards.

Use FoodDocs' smart Food Safety Management System to get digital solutions with smart ways to help you calibrate thermometers.

- Calibration log to help record calibration tasks

- Detailed instructions to ensure accurate calibration

- Smart notification to remind your team about calibration schedules

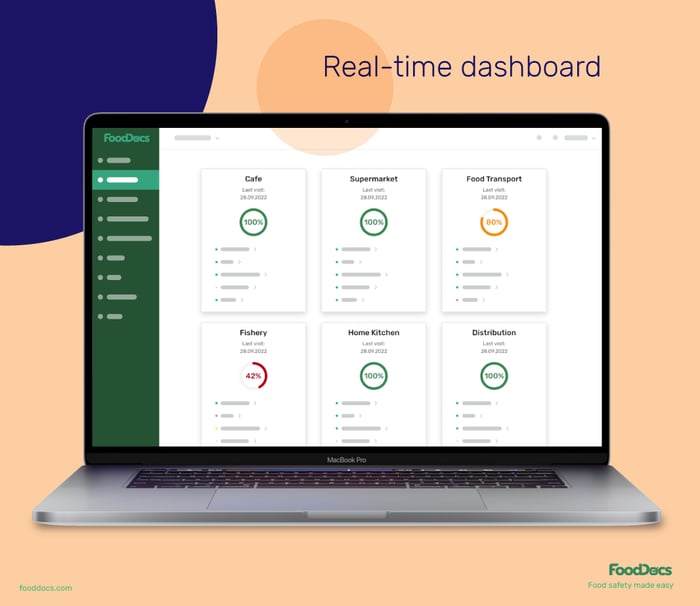

- Real-time dashboard to oversee tasks easily

Calibration log to help record calibration tasks

Once you signup with us, our system automatically generates a Thermometer Calibration Log.

This feature can help food handlers record calibration readings accurately without piling up all the information. The data you log in is safely stored in cloud-based storage along with your other digital documents.

Our digital Calibration Logs are integration-ready. All appliance thermometers for smart equipment will automatically log the information to our system. All that is left to do is to verify the information.

Calibration log from FoodDocs software

Detailed instructions to ensure accurate calibration

Our automatically generated monitoring logs are equipped with step-by-step instructions on how to execute the monitoring task. As such, managers can use these instructions to teach food handlers how to calibrate thermometers properly.

Get detailed instructions on boiling-point and ice-point methods to help ensure accurate calibrations in your food business. Using this feature, you can ensure that all thermometers will give accurate temperature readings.

You can also upload your versions of the calibration instructions to make the system more suited for your business.

Smart notification to remind your team about calibration schedules

Our system features a smart notification system that ensures the calibration process is performed on time and correctly. Using our mobile application, food handlers are alerted through push notifications when the calibration task must be done.

This feature can help you ensure that thermometers are regularly calibrated before use; therefore, all temperature readings are accurate and food safety is always ensured.

Real-time dashboard to oversee tasks easily

You will also get a real-time dashboard, which features an overview of your food safety status and everyday operations. Use this dashboard to save at least 20% of your time supervising your operations.

The dashboard can show you areas where signs of inaccurate readings may be occurring and can be used to identify areas that need improvement. You can quickly address monitoring tasks that use an inaccurate thermometer and issue a calibration task immediately, maintaining food safety at all times.

Real-time dashboard from FoodDocs software

Using our digital Food Safety Management System, you can get automatically generated monitoring forms and protocols after a brief setup process that takes only 15 minutes.

Improve your food safety compliance efficiency and ensure that all your thermometers are calibrated accordingly with our digital FSMS at FoodDocs.

Book a free demo call to learn more about the convenience that our system can bring to your food business.

Frequently Asked Questions (FAQs)

What is an easy way to calibrate your thermometer?

Two of the easiest ways to calibrate your thermometer and improve the accuracy of readings are the boiling point method and the ice point method.

What is the easiest and safest way to calibrate a thermometer?

In terms of safety, the ice point method poses less harm than the boiling point method. The latter method can cause burns when the vessel containing the boiling water is not properly handled.

How do you know if your thermometer is accurate?

To determine whether your thermometer is accurate or not, use a glass of ice-water mixture and dip the thermometer probe or temperature sensors in. If the thermometer reading registers 32°F or 0°C, then the thermometer gives accurate temperature readings. You can also opt to use NIST-certified reference thermometers for this task.

What is the most accurate method for calibrating a thermometer?

The ice-point method is generally considered the most accurate for calibrating a thermometer for a correct temperature reading.

What is one effective way to calibrate a thermometer?

One effective way to calibrate a thermometer is through the boiling-point method. Place the thermometer probe in a pot of boiling water (212°F or 100°C) without touching the sides or bottom. Allow it to stabilize, and if it reads differently, note the difference and adjust future readings accordingly.

How to reset a thermometer?

To reset a thermometer, consult the user manual or manufacturer's instructions, as resetting methods can vary. Generally, it involves pressing a calibration reset button, or a specific button combination, to restore the thermometer to its default settings. This action is commonly necessary for digital thermometers.

How to calibrate a meat thermometer that starts at 120?

Calibrating a meat thermometer that starts at 120°F can be done by adjusting readings based on the known differences. For instance, if the thermometer consistently reads 5°F too high, subtract 5°F from the indicated temperature when using it for meat, considering the discrepancy in your cooking process.