Three types of hazards that make food unsafe

Learn more about the three types of food safety hazards, how to prevent them, and the most significant cases related to them.

A well-prepared and equipped food business can effectively control food safety hazards and protect its consumers from ...

A well-prepared and equipped food business can effectively control food safety hazards and protect its consumers from illnesses.

The food industry is a very complex part of a community. Several factors, including biological, physical, and chemical objects, are combined and come in contact with the processing of food. This essence of the foodservice industry tells us that food safety hazards will never be absent from the food chain. These hazards will always be present in any food business.

Food hazards can only be prevented, minimised, or eliminated by implementing preventive and control measures. Fortunately, there are many smart ways to manage food safety hazards efficiently. In this article, we will cover the main knowledge one should know about food safety hazards and how to limit them from occurring.

Food safety hazards are the main cause of foodborne illnesses. They are capable of causing diseases or injuries to consumers, which can be mild or life-threatening.

WHAT WE'LL COVER:

Food safety hazards are any substance found within the food supply chain that can contaminate food materials and cause unwanted health conditions to the public. The presence of food safety hazards in products is considered as food contamination.

These hazards contaminate raw materials and finished products due to exposure to potential sources. Contamination by food safety hazards can occur anywhere in the food supply chain, including harvesting, transit, processing, packaging, delivery, serving, and even storage.

Food safety hazards can either be naturally present in foods or be introduced from external sources. Different foods have their association with particular food safety hazards. An example would be the high relationship of peanuts to potent fungal toxins such as aflatoxin. Since this type of food safety hazard can be deadly with long-term exposure, strict food safety laws have been established for them.

Additionally, chemical food safety hazards such as acrylamide are common indicators of temperature abuse for heated products and can cause adverse health effects.

Any type of food safety hazard can potentially cause significant foodborne illnesses and injury, especially for immunocompromised individuals such as the elderly, children, and pregnant women. All food handlers must know basic information about food safety hazards. This task is the first step in knowing how to address them properly.

Each type of food safety hazard would need a specific food safety practice to control them.

Ensure that all potential food safety hazards are controlled in your food business with the help of our comprehensive and smart Food Safety Management System. Get automatically generated monitoring logs and checklists equipped with detailed instructions from our software. Use these checklists to ensure control over every food safety hazard accurately in your food establishment.

Food safety hazards can be classified into four (4) types:

Each category describes the nature of the food safety hazard and gives food handlers an idea of the proper practices needed to control them.

These types of food safety hazards include all substances that can cause foodborne illnesses or allergic reactions in consumers.

Depending on factors such as the level of contamination, the likelihood of occurrence, and the potential damage it can cause, these food safety hazards can mildly or significantly affect public health.

Below we discuss each type of hazard and identify its common sources.

Biological hazards are food safety contaminants that originate from living organisms that include:

These hazards can significantly affect the health of the public by causing foodborne illnesses that can range from mild to very severe. They are different from beneficial microorganisms used in fermentation or as probiotics.

Biological hazards may also include natural toxins produced by these pathogens. Biological hazards are the most common causes of outbreaks in the food industry.

Food safety hazards such as bacteria and viruses can easily be transferred to food from cross-contamination. These hazards are also dependent on factors surrounding the host food, such as:

In the food industry, these factors are better known through the acronym FATTOM.

Depending on the presence of these factors, the surviving microbiological hazards may vary. Some dangerous pathogens, such as Clostridium botulinum, known for its potency to kill consumers, can only survive in conditions without oxygen and low acidity, such as in canned goods.

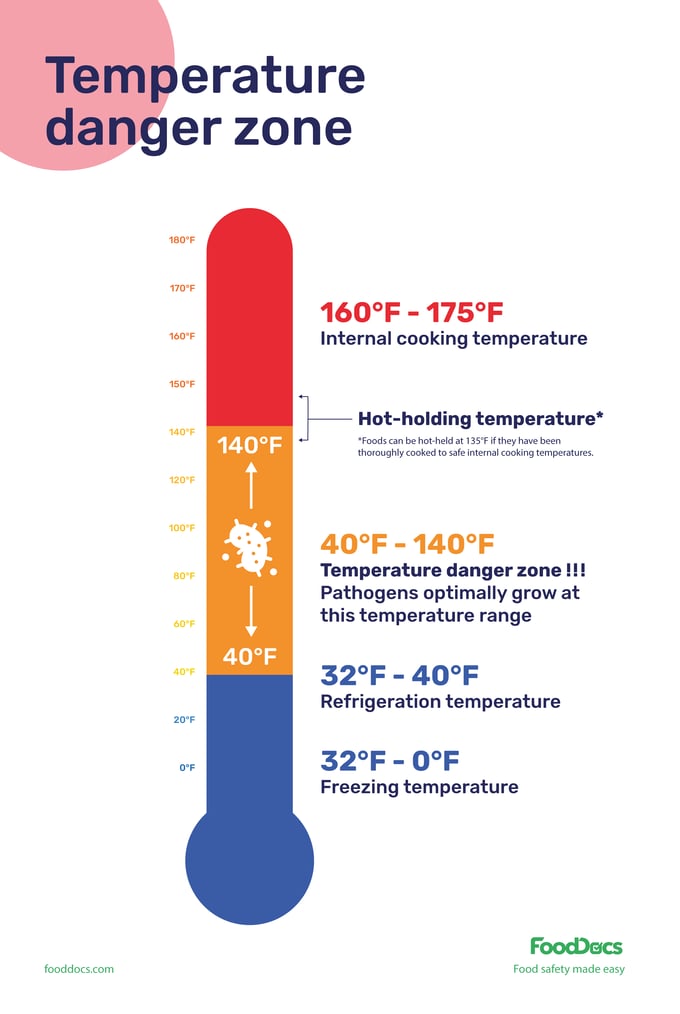

These conditions also determine the rate at which pathogenic hazards multiply. An example of this condition would be the principle behind the temperature danger zone, which is 40°F and 140°F (5°C and 60°C).

This temperature range is where most pathogens thrive best and can easily spoil food. Precautions for biological hazards include proper handling practices such as handwashing, regular cleaning, chilling of foods, and thorough cooking.

Biological hazards are very common in the food service area and food production sites. Their presence is even larger during the harvesting of raw materials.

Here are 6 most common sources of biological hazards within the food supply chain:

Additionally, different types of raw meats may contain and are highly susceptible to microbiological hazards. A good example is the common knowledge that poultry meat contains Salmonella and therefore needs thorough cooking. Depending on the quality of the raw materials, the initial load of these hazards may determine how fast spoilage can occur.

In addition to the natural pathogens on human skin, food handlers are one of the fastest carriers of biological food hazards around. This case occurs as what we know as cross-contamination. Without proper food handling practices, employees can spread biological hazards by holding an unclean surface or food to the food being prepared.

Food handlers are also common hosts of viruses, which can be transferred to the food being prepared.

In the case of refrigerated storage, mixing raw and ready-to-eat foods can spread contamination. Trapped juices or pieces of food in the storage area can also start as a cause of accumulating biological hazards.

Some pathogens can produce colonies on surfaces that protect them from regular cleaning procedures. This event can be caused by inefficient cleaning of surfaces. As such, routine cleaning and sanitation procedures are required to prevent this.

The other way pests can spread biological hazards is through their faeces or urine. Pests droppings are commonly very small and can sometimes go unnoticed. They can easily work their way into the food being prepared.

Biological hazards can come from different sources and cause significant harm when uncontrolled. Some of the best ways to control these hazards include proper food hygiene and thorough cooking of food.

Preventing and controlling biological hazards through strict adherence to food safety protocols, regular sanitation, and employee training are essential to ensure the safety and quality of food products served to consumers.

Read more about biological hazards here.

Hazards under this category are chemical substances naturally occurring or added to foods that can cause foodborne illness or human injury.

Natural chemical hazards are harmful substances that are innately present in foods. A good example of natural chemical hazards is saponins from legumes. This compound is a natural part of the toxic defence of plants against harmful microorganisms and insects. This compound can be risky when ingested in high amounts. As such, legumes are pretreated before cooking or consumption.

In addition to naturally occurring chemical hazards, intentionally added ones such as food additives and preservatives are also present in the industry and can be considered chemical contaminants. These additives and preservatives become hazardous when used excessively or without proper labelling.

On the other hand, chemicals such as pesticide residues, fertilizers, antibiotics, machine oil, and toxic metal compounds are considered unintentional chemical hazards or accidental contamination and have serious effects on humans when ingested.

As mentioned, chemical hazards can be naturally present in materials, intentionally added, or unintentionally introduced to foods. In some cases, chemical hazards can also occur due to processing abuse, especially in heating treatments. Below are some of the common sources of chemical hazards in the food industry:

These compounds become considered chemical contamination when used in unregulated amounts beyond the specified standards.

Unlike other types of hazards, chemical hazards can cause long-term effects with symptoms that can only manifest after a while. Food businesses must be prepared in identifying, controlling, and mitigating chemical hazards to ensure the safety and integrity of their food products.

Strict adherence to food safety regulations, proper handling and storage of chemicals, accurate labelling, and effective communication with consumers about potential allergens are vital in preventing chemical-related incidents and protecting public health.

Read more about chemical hazards here.

Physical hazards are any foreign objects or extraneous material that can contaminate food and cause injury or act as a precursor for the growth of pathogens. Physical hazards can be objects, such as the following:

This type of hazard can naturally come from food materials such as bones from meat, stems from fruits, or shells from seafood. Other types of physical hazards can come unnaturally from broken production materials, including plastics, glass, textiles, or jewellery.

Contaminants such as nails and hair can also come from food handlers. Physical hazards can sometimes be prevented through physical observations and inspection. At times during large-volume productions, an automatic detector can be used.

There are a variety of sources of physical hazards in the production line. They can come from pests, machines, or the food handlers themselves. Detection of physical hazards is important as it can also attract or spread other types of hazards. Here are some common sources of physical hazards:

Preventing physical contamination is crucial for ensuring food safety and protecting consumers from potential hazards. Depending on the size and composition of a physical hazard, the food safety issue they can cause may vary. Some can cause choking, whereas others can cause cutting or lesions.

Read more about physical food safety hazards here.

Allergens are food safety hazards caused by proteins that the immune system of some individuals mistake as dangerous foreign matter and cause dangerous reactions. These proteins are natural parts of some foods.

Allergenic reactions can cause symptoms that include itching in the mouth or other parts of the skin, hives, swelling, abdominal pain, nausea, and vomiting.

In more serious cases, allergens can even cause anaphylaxis which is a severe allergic reaction that causes the blood pressure to drop and for the airways to tighten and block breathing.

In the US, more than 20 million citizens have been reported to have food allergies. In contrast, approximately 2 million people in the UK are diagnosed with at least one food allergy.

The early detection of allergens is a must for individuals. Because the results can be life-threatening, food businesses must be wary of the food they serve and properly communicate with consumers about the potential allergens present.

Notes on the menu or a food allergen poster can be helpful for food businesses. In the US, there are 8 common food allergens, whereas, in the UK, 14 are recognised.

Common allergens

Downloadable Food Allergen Poster

By law, food establishments and manufacturers must declare any food allergen in a food product as part of the allergen management program. Indications may be added on packaging labels or menus as long as they are visible and easy to spot.

There is no way of telling whether a consumer has food allergies by visual observation. As such, it is the responsibility of a food business team to inform them of the potential risks in your food products.

You can read more about the importance of food labelling and the UK food safety law concerning food allergens here.

Each year, at least 600 million people become afflicted with foodborne illnesses because of contaminated foods in a year.

The first step to preventing these foodborne illnesses is properly identifying food safety hazards.

Identification and analysis are proactive approaches to addressing the potential effects of these safety hazards. The basis for hazard identification must be from established and reliable resources, as public health depends on them.

More than just simple foodborne diseases, food safety hazards can cause death or serious injuries in severe cases. This does not only pose a great threat to public health but your food business as well.

Below are different ways and basis that you can use in identifying hazards:

Hazard analysis is the first step of any food safety plan. This step allows you to identify potential hazards in every step of your production process and analyze each one for its potential risk and occurrence.

The process of analyzing hazards involves an organized set of steps that break down the entire food production process. All types of hazards are then identified in each step. This is a collaborative effort by the entire team.

Based on the severity of the identified hazards, the team can establish proper control measures. Regular hazard analysis allows for continuous improvement of food safety practices. As new information and data become available, food safety professionals can update their hazard identification processes to stay ahead of emerging risks.

Over the years and as an effort of the scientific community to keep the food industry safe, related literature on common and more complicated food safety hazards has been studied. These hazards are mostly categorised based on the type of food being prepared. These sets of information contain minimum and maximum residue limits that are allowed for a particular food safety hazard as well as appropriate handling practices to address them.

Peer-reviewed scientific articles on common food safety hazards are normally available online. Alternatively, you can consult with your local food safety authority or larger food safety agencies on the potential food safety hazards and their allowable limits.

In addition to scientific studies, news on cases of foodborne illnesses offers valuable information. These reports of food poisoning include information on any causative agent and the lapses in food handling practices that could have led to the outbreak.

News can include minor cases of foodborne illnesses, major outbreaks, food recalls, significant violations, and new food safety regulations. Food safety agencies usually compile major food poisoning outbreaks as records that you can access to equip your team with proper hazard analysis fully.

In making effective food safety systems, it's important to communicate the plans and procedures with your entire team. During this process, you can gather information from them as well. Those who have already been in the food industry for a long time can offer valuable information from their experiences.

Additionally, you can seek the expertise of food safety consultants in identifying food safety hazards in your process. Their experience can assure you that hazards will be properly identified and analysed.

Food safety hazards, although they will always be present, can surely be controlled or eliminated.

There are many food safety and hygiene practices that have been devised to address different food safety hazards and are proven effective. The first step in knowing how to prevent poor food safety and these hazards is having substantial knowledge about them.

When food handlers know what they should monitor and which practices should be avoided, work becomes faster and more efficient. This also allows your team to identify which practices would be most effective in eliminating specific food safety hazards. It also gives them an idea of which food safety laws must be followed.

Below are some ways that you could implement in your food business to help address food safety hazards:

With sufficient knowledge about the present food safety hazards in your operations, you can formulate plans to address them. Proper identification means listing the potential sources of these hazards and factors that can promote their presence.

From this information, you can develop food safety practices targeting their weaknesses or root cause. Addressing these food safety hazards before they cause widespread foodborne illnesses is more economical and effective in protecting consumer health.

Use our Free Hazard Analysis template to make identifying hazards easier and more organized.

As a food business owner, it's normal to have more than one supplier for the same product. You do not have direct control over their food safety practices, but you can set standards that they will have to follow.

Because you cannot regularly inspect their management system, you can request certificates and test results as proof of the safety of their supplies.

This step requires any supplier to uphold very high standards of food safety practices to satisfy different businesses. In addition, receiving high-quality materials removes the extra burden of implementing very strict inspection standards and preconditioning on your part.

Obviously, food safety hazards can be controlled with basic food safety practices. This step means following basic food safety rules, including:

These basic steps are the foundation of most food safety practices.

They aim to prevent the spread of pathogenic hazards and control their growth. Steps such as cleaning include personal hygiene practices, proper handwashing, and sanitation of different food contact surfaces.

Cooking, on the other hand, eliminates biological food safety hazards by subjecting the food to high temperatures that are unfavourable for pathogens.

Lastly, to prevent the further spread of pathogens and to control their growth, both raw foods and cooked products are chilled in refrigerated conditions.

Learn more about the four core food safety practices here.

Waste materials attract pests, and these pests invite a multitude of food safety hazards. Controlling these factors requires a strict management system to store and dispose of waste materials properly.

Once this has been managed, the first step to eradicating pests, which is removing their food source, is covered. Additionally, potential shelters for pests such as dark spots or rarely used storage areas must be kept clean and regularly checked.

A holistic approach to addressing concerns regarding food safety hazards is having a comprehensive food safety management system (FSMS).

This program contains sets of food handling practices that are particular for the food safety hazards in your operations.

Additionally, food safety rules and regulations are considered in making an FSMS as a reference for monitoring. To ensure that these practices are followed and that laws and regulations are always in check, monitoring procedures and verification methods must be included in an FSMS.

In addition to these suggestions, higher food safety systems are available in the food industry. These systems include HACCP, ISO, and FSSC, which implement strict hygiene and safety standards to protect public health.

In addressing food safety hazards, remember that preventing their spread or mere existence is more economically sound and safe for consumers. This lessens the problems of controlling an outbreak and its negative effects on your food business.

Learn more about getting a comprehensive and smart food safety management system in the next section.

With proper identification, analysis, processing, and monitoring, food safety hazards can be significantly controlled. To do this, food business owners must be able to implement a working and comprehensive FSMS in their food business system.

Use FoodDocs' digital Food Safety Management System powered by artificial intelligence to take out the laborious process of food safety. Our system can generate this program for you in a digital format and just an average of 15 minutes!

When you sign up with us at FoodDocs for our digital FSMS services, you can get the following benefits:

Our smart Food Safety Management System comes with an intuitive solution to remind food handlers of upcoming food safety tasks. With the help of our smart notification system, employees can receive alerts whenever there is a task that needs to be done.

Using this smart solution, you can ensure that all tasks related to controlling food hazards are done on time. Receive notifications through our smart food safety app.

Smart notification system from the FoodDocs software

Food business managers can save more time using our smart Food Safety System. You can get a real-time overview from our dashboard that shows your business's food safety status. This overview reveals which tasks are done correctly and which require more attention.

With the help of this smart feature, you can save up to 20% of your time from managing your team. Get a clear overview of all branches and monitor tasks to ensure hazards are consistently controlled.

Real-time dashboard from FoodDocs software

Get digital monitoring tasks and checklists based on your business profile. These monitoring tasks can help your team ensure that all parameters needed to be monitored for controlling hazards are accurately recorded.

All monitoring logs and checklists can be further customized to fit your unique operations.

Ensure that all of your employees know how to accurately control food hazards with the help of our detailed instructions. Our system automatically generates monitoring logs with step-by-step instructions based on your business profile.

Food safety managers can use these instructions to train food handlers and ensure that their tasks are done accurately and effectively to control hazards. The instructions are available to serve as a reference for food handlers.

You can also upload your own versions as images or videos.

Choose to become more sustainable when monitoring your everyday operations by going digital. Leave behind all paper-based monitoring procedures and make your workforce more efficient as you shift to a digital platform.

With our smart FSMS at FoodDocs, you can rest easy that all food safety hazards can be addressed in a timely and efficient manner. Our system can help you remain compliant with the most significant food safety laws and regulations and protect public health from food safety risks.

Start making your digital FSMS in just 15 minutes with our free 14-day trial, and continue your journey with us by availing of our plans.

To better understand more about food safety hazards, here are a few frequently asked questions about this topic:

The food hazard definition refers to any biological, physical, or chemical agent that can cause foodborne illness or injury when present in food.

The main cause of food poisoning is usually biological hazards, particularly pathogenic bacteria like Salmonella, Escherichia coli (E. coli), and Campylobacter.

Poor waste management can lead to biological hazards, as improper disposal of food waste can attract pests and contaminate food with bacteria and pathogens. Additionally, chemical hazards can result from improper disposal of cleaning agents and other chemicals, leading to potential contamination of food.

The main hazard associated with the delivery of frozen food is a biological hazard due to improper temperature control. During delivery, foods are advised to be stored in a vehicle with a controlled temperature. The target temperature prevents the growth of any foodborne illness.

Sick food handlers are capable of creating biological food safety hazards because of the virus that they currently have. They can spread this hazard through cross-contamination and significantly increase the risk of food poisoning.

Seven of the most common kitchen hazards include:

Five of the most important food safety rules in the kitchen include:

Learn more about the three types of food safety hazards, how to prevent them, and the most significant cases related to them.

Microbiological contamination of food refers to the unwanted presence of pathogenic microorganisms in food. Learn how to avoid it and control it.

Learning how to write a HACCP plan means knowing that this food safety system is based on scientific facts and that all steps must be validated.